POWER AND RENEWABLE ENERGY

REVOLUTIONIZE YOUR ENERGY INFRASTRUCTURE: HARNESSING RENEWABLE POWER FOR A SUSTAINABLE TOMORROW

As a leading provider of cutting-edge technologies and services, we assist businesses in streamlining their operations, optimizing their productivity, and staying competitive.

Whether our clients seek to optimize their manufacturing processes, cut costs, or increase productivity, our customized solutions are intended to fit their specific requirements. Our skilled professionals have decades of expertise in the manufacturing and automation industries, and we are committed to offering our clients the most outstanding quality of service and support.

Top 5 Challenges for Power and Renewable Equipment Designers

1. Energy Storage and Management

- Problem: Balancing energy generation with consumption is challenging, especially in renewable systems with intermittent supply (e.g., solar or wind).

- Solution: Advanced energy storage solutions such as high-capacity batteries, supercapacitors, and energy management systems (EMS) that optimize storage, distribution, and grid interaction.

2. Grid Integration and Stability

- Problem: Integrating renewable energy sources into the grid can create instability due to fluctuating power outputs and the need for synchronization.

- Solution: Inverters with grid-tied synchronization, power conditioning equipment, and smart grid technologies to maintain grid stability and ensure seamless integration.

3. Efficiency and Loss Minimization

- Problem: Energy losses during conversion, transmission, and storage reduce the system's overall efficiency.

- Solution: High-efficiency power converters, transformers, and advanced materials that reduce losses while maintaining performance under varying loads.

4. Environmental and Climatic Durability

- Problem: Renewable energy systems, particularly solar and wind, are exposed to harsh environmental conditions such as extreme temperatures, humidity, and storms.

- Solution: Ruggedized, weather-resistant components such as corrosion-resistant enclosures, UV-stabilized materials, and robust mechanical supports for long-term reliability.

5. Scalability and Modularity

- Problem: Renewable energy projects often require the ability to scale up or down based on demand, making fixed-capacity systems less practical.

- Solution: Modular power generation and storage solutions that can be expanded or reconfigured easily, along with flexible control systems to adapt to changing capacity needs.

Featured Products

PLC

HMI

Remote I/O

Relays

Enhance power distribution and efficiency in renewable energy with cutting-edge relay technology for optimal performance.

Circuit Breakers

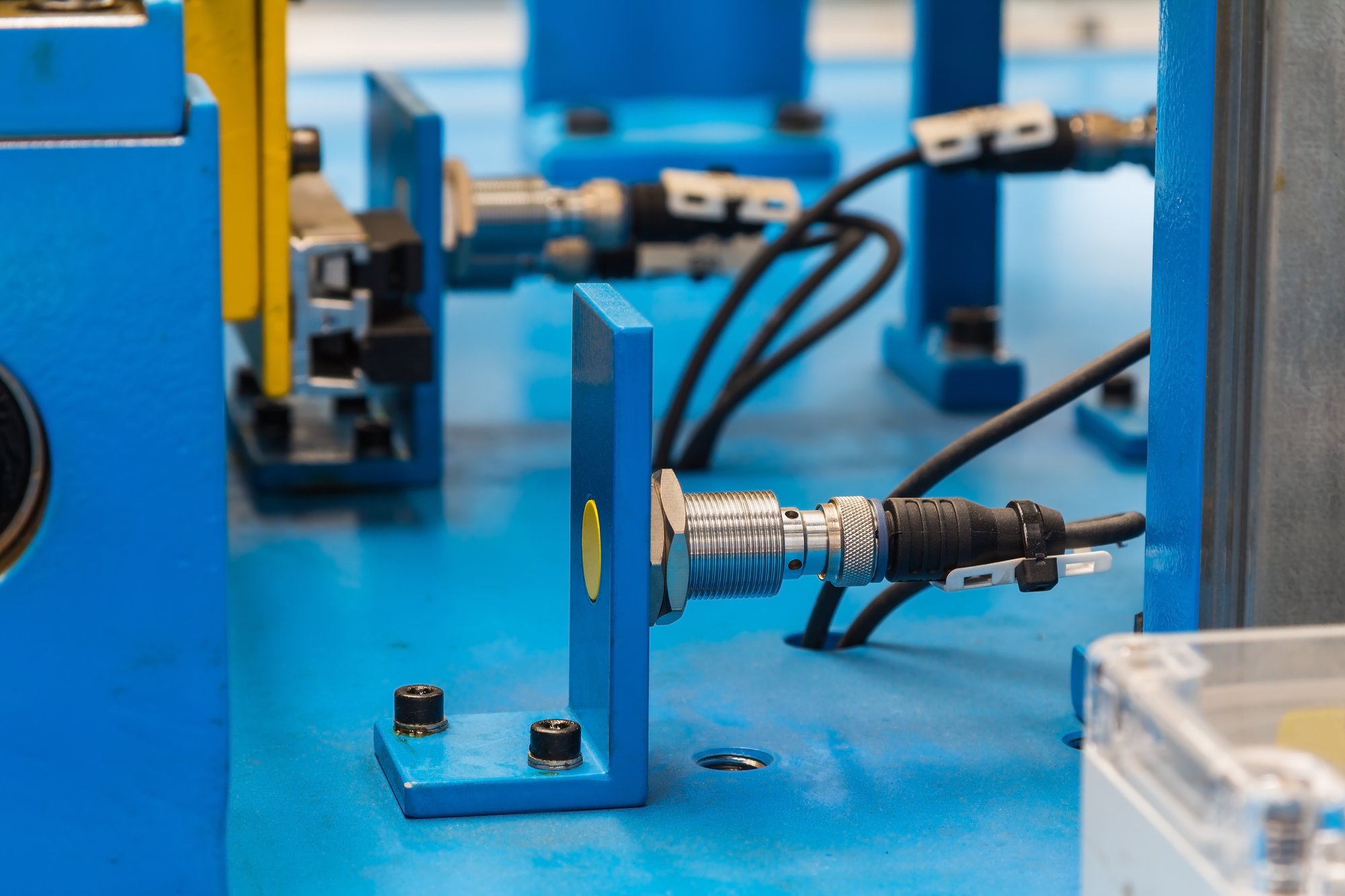

Sensors

Inverters

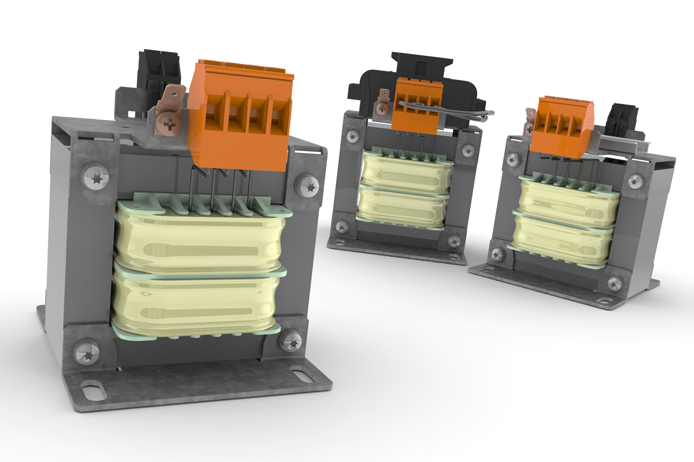

Transformers

Maximize Power Efficiency and Performance: Transform Your Energy Infrastructure with Cutting-Edge Transformers.

Power Conditioning

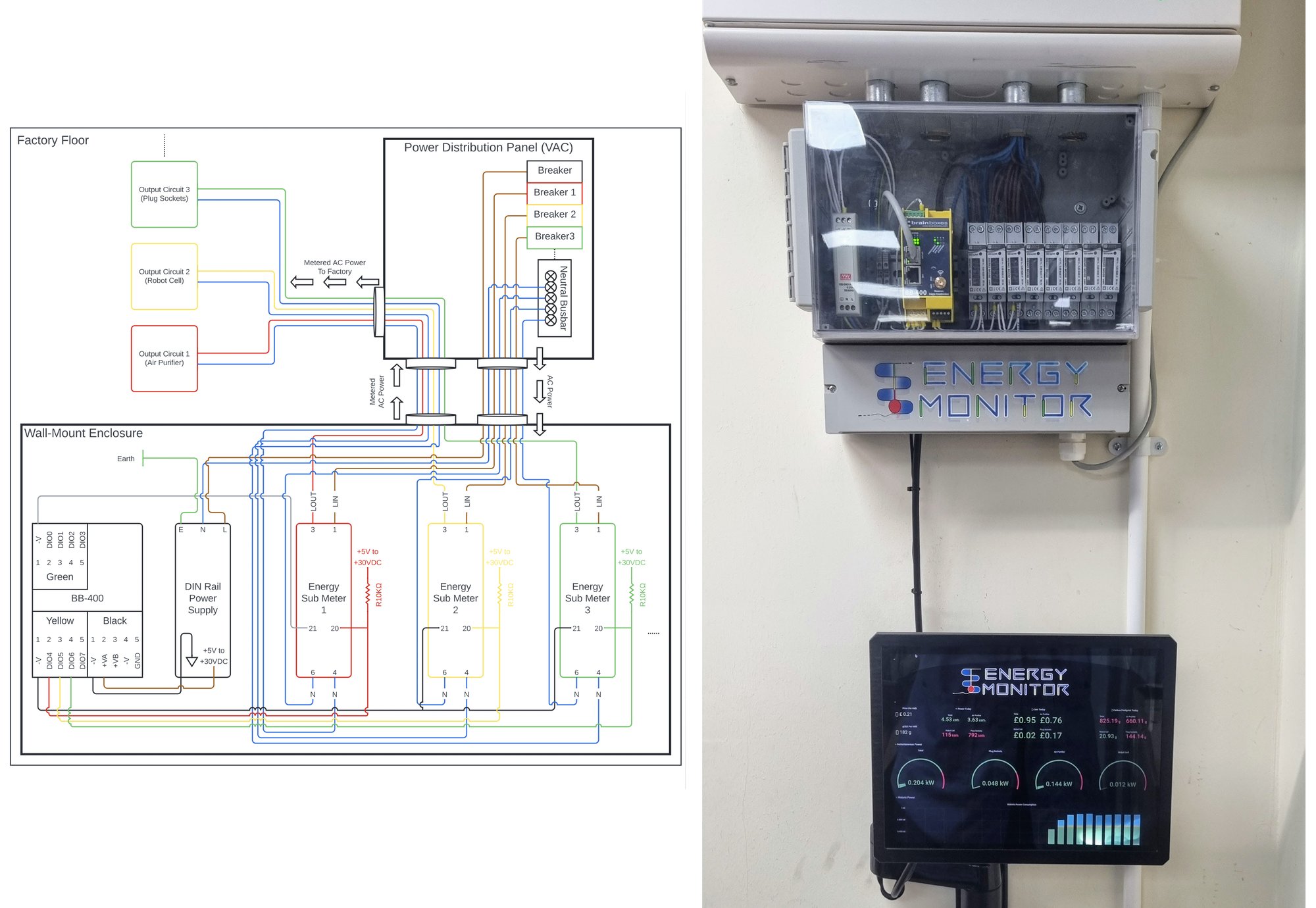

Energy Monitoring

Switchgear

-

With the ability to monitor and control production processes in real-time, businesses can quickly identify and resolve issues, minimizing downtime and maximizing productivity.

-

With Ethernet communications, businesses can create a reliable and efficient network infrastructure that supports real-time control and monitoring of production processes.

-

Businesses need to prioritize safety in their industrial processes to ensure the well-being of their employees and equipment.

-

Automation systems and control panel building technologies can help businesses reduce labor costs and increase production output by streamlining and automating routine tasks.

-

For systems that are less then 600V, considering a busbar systems can reduce panel size by 25%.

-

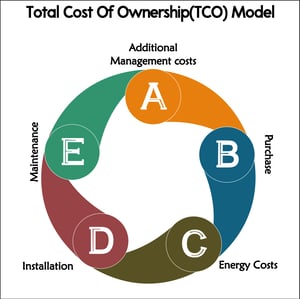

When considering TCO, it's crucial to consider maintenance costs, software and licensees, training, energy efficiency, downtime, and productivity factors.

HOW CAN WE HELP DESIGN YOUR NEXT SYSTEM?

- Control

- Communications

- Safety

- Labor

- Space

- TCO

Control

An electrical control system is a physical interconnection of devices that influences the behavior of other devices or systems. It comprises an input, a process, and an output. Input devices such as sensors gather and respond to information and control a physical process using electrical energy as an output action.

An electrical control system is a physical interconnection of devices that influences the behavior of other devices or systems. It comprises an input, a process, and an output. Input devices such as sensors gather and respond to information and control a physical process using electrical energy as an output action.

Control systems enable businesses to optimize production processes, reduce costs, and maintain consistent product quality by monitoring and regulating various industrial processes. Automation and electrical control panels allow manufacturers to streamline processes, reduce labor costs, and minimize the risk of human error. Control systems also enable companies to manage their production processes, ensure safety, and maximize productivity.

Communcations

Industrial networks and Ethernet communications enable seamless and fast data exchange between machines, devices, and components, allowing businesses to optimize production processes, reduce costs, and maintain consistent product quality.

Industrial networks and Ethernet communications enable seamless and fast data exchange between machines, devices, and components, allowing businesses to optimize production processes, reduce costs, and maintain consistent product quality.

Industrial networks and Ethernet communications enable seamless and fast data exchange between various machines, devices, and components, providing a foundation for a fully integrated and interconnected industrial ecosystem.

Safety

Safety systems are essential for ensuring the safety of employees and equipment in an industrial environment, such as emergency shutdown systems, interlock systems, fire suppression systems, and personnel protection systems. By integrating safety systems into industrial control systems, businesses can minimize the risk of accidents and protect their employees and customers from injury or harm.

Safety systems are essential for ensuring the safety of employees and equipment in an industrial environment, such as emergency shutdown systems, interlock systems, fire suppression systems, and personnel protection systems. By integrating safety systems into industrial control systems, businesses can minimize the risk of accidents and protect their employees and customers from injury or harm.

Safety is critical in an industrial setting that uses automation, electrical control panels, and industrial control components, ensuring the safety of employees, equipment, and anyone who may come into contact with them. The most important thing for a business is to minimize the risk of accidents and downtime.

Labor Savings

Automation systems and control panel building technologies can help businesses reduce labor costs and increase production output by streamlining and automating routine tasks. By utilizing automated equipment and robotics, companies can improve their production processes and reduce the need for manual labor. Reducing manual work can significantly save labor costs and improve overall efficiency. In addition, automation systems and industrial control component technology can help businesses minimize the risk of human error, ensuring consistent and reliable product quality.

Automation systems and control panel building technologies can help businesses reduce labor costs and increase production output by streamlining and automating routine tasks. By utilizing automated equipment and robotics, companies can improve their production processes and reduce the need for manual labor. Reducing manual work can significantly save labor costs and improve overall efficiency. In addition, automation systems and industrial control component technology can help businesses minimize the risk of human error, ensuring consistent and reliable product quality.

Companies must invest in the right technology and systems to effectively create savings, and partner with vendors to consult on new machines and processes. By doing so, businesses can benefit from increased efficiency, productivity, and profitability and maintain a competitive edge in their industry.

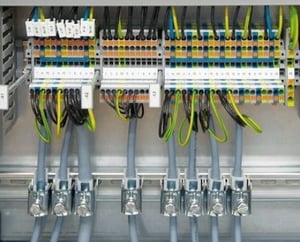

Space Savings

Saving space in an industrial control panel is essential to optimize available space and maximize efficiency. Using compact components such as miniature circuit breakers, slim relays, and smaller or multi-level terminal blocks can help save space in a control panel.

Saving space in an industrial control panel is essential to optimize available space and maximize efficiency. Using compact components such as miniature circuit breakers, slim relays, and smaller or multi-level terminal blocks can help save space in a control panel.

When designing you should use compact components, plan the layout, use modular designs, utilize vertical space, optimize wiring, and use color-coded wiring. These strategies can help businesses save space in their control panels and optimize available space, leading to improved efficiency, reduced costs, and increased productivity.

Total Cost of Ownership

When building or specifying industrial equipment for a manufacturing environment, it is important to consider the total cost of ownership (TCO). TCO considers not only the upfront cost of purchasing the equipment, but also the cost of operating and maintaining it over its lifespan. This includes maintenance costs, energy efficiency, downtime, and productivity factors. By analyzing these factors, businesses can make more informed decisions about which equipment to purchase and can optimize their overall costs over the long term. This can lead to improved efficiency, reduced costs, and increased profitability.

When building or specifying industrial equipment for a manufacturing environment, it is important to consider the total cost of ownership (TCO). TCO considers not only the upfront cost of purchasing the equipment, but also the cost of operating and maintaining it over its lifespan. This includes maintenance costs, energy efficiency, downtime, and productivity factors. By analyzing these factors, businesses can make more informed decisions about which equipment to purchase and can optimize their overall costs over the long term. This can lead to improved efficiency, reduced costs, and increased profitability.