RELIABLE CONTROLS FOR HIGH PERFORMANCE SYSTEMS

Dynamic partners with your engineering team to build production-ready machines powered by reliable control hardware, modern network architecture, and rugged electro-mechanical systems.

From Power To Connectivity, we help future-proof your designs

Dynamic helps engineering teams build smarter, resilient machines by focusing on the core systems that matter most.

From stable power and secure wiring to intelligent control and reliable connectivity, every element is chosen for performance, protection, and future scalability.

Stable Power & Electrical Safety = Reliable Machine Foundation

Ensure consistent, protected electrical performance.

- System Focus: Power supplies, breakers, surge protectors, disconnects

- Engineering Advantage: Voltage stability, inrush protection, compliance-ready design

Machine Intelligence & Control = Intelligent Operations

Bring your system to life with smart, responsive controls.- System Focus: PLCs, HMIs, motion control, safety relays

- Engineering Advantage: Scalable, deterministic control with future upgrade paths

Industrial Data & Connectivity = System Communication

Enable real-time machine insight and integration.- System Focus: Ethernet switches, I/O modules, protocol gateways

- Engineering Advantage: Edge computing, secure remote access, SCADA/IIoT readiness

Secure Wiring & Cable Integrity = Clean Infrastructure

Connect every component with reliability and traceability.

- System Focus: Industrial-grade cables, connectors, labeling, cable trays, wire duct

- Engineering Advantage: Reduce EMI, streamline maintenance, improve build quality

Thermal Management & Protection = Environmental Safeguards

Keep systems cool, dry, and protected from the elements.- System Focus: Enclosures, fans, cooling units, panel heaters

- Engineering Advantage: Match IP/NEMA ratings to the environment, prevent shutdowns.

Products From Specialized Manufacturers = Project-Based Personalization

We only partner with established and certified parts providers, no exceptions- System Focus: Engineering components

- Engineering Advantage: Custom parts sourced for your solutions.

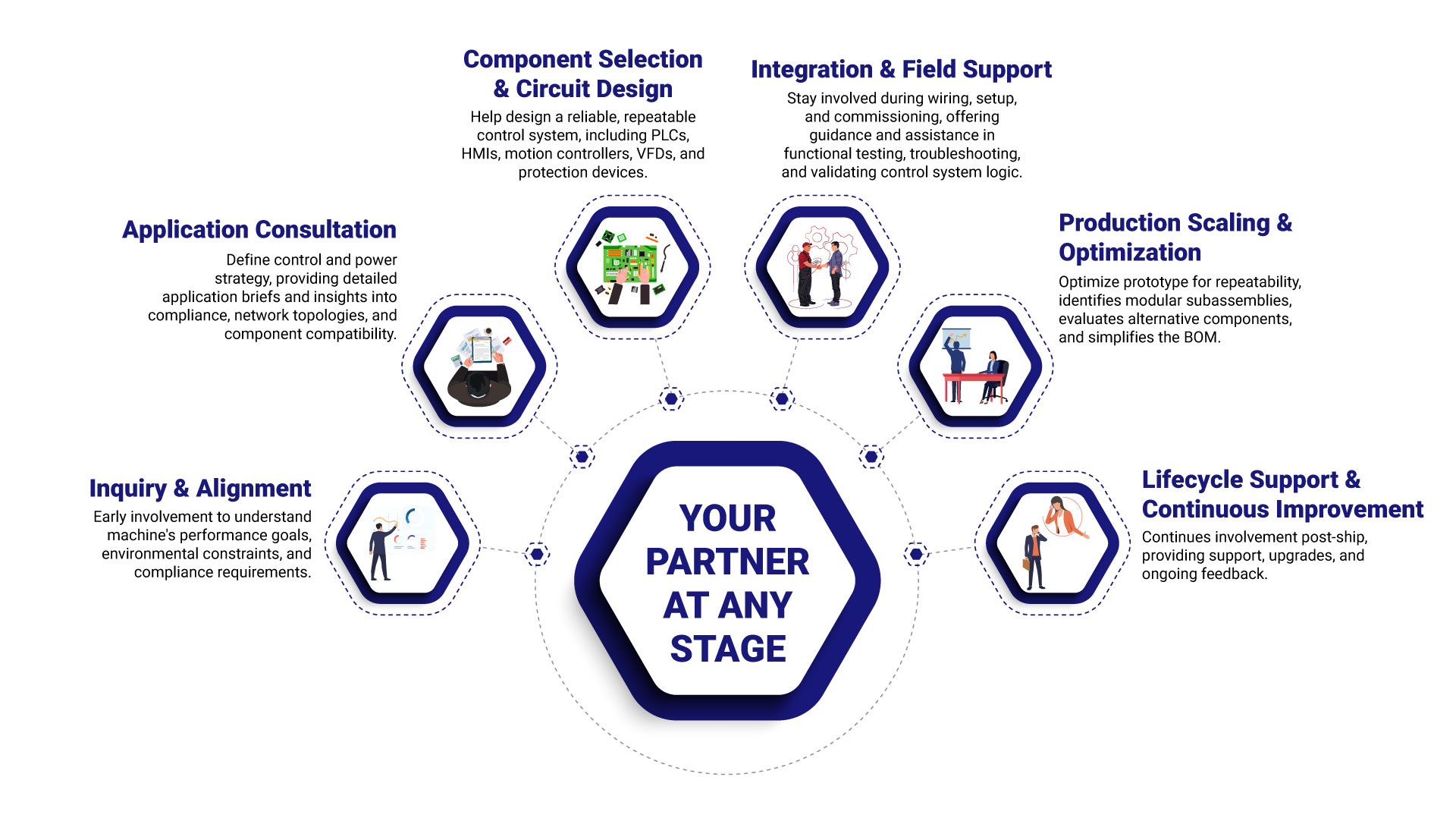

What we do: More Than just a part number

We’re not a distributor, we’re the technical team behind the manufacturers. Chosen, trained, and trusted to represent top-tier component brands, Dynamic partners with OEMs and distributors alike to help build better machines.

We help you make better design decisions by combining component expertise with real-world application knowledge and by offering personalized consultations and onsite training to guide your team from concept through commissioning.

Whether you're designing next-generation production equipment, automating a legacy process, or launching a new product line, we bring system-level insight to every decision and feed field learnings back to our manufacturing partners to continually improve our product solutions.

Your All-in-One Industrial Controls Partner

Design Consultation

Your Project Journey

Whether you’re defining a new system or refining an existing one, Dynamic helps engineers address power and control challenges that affect performance over time.

Systems Built for Scale and Sustainability

From scalable controls to ruggedized connectors, we help you build machines that deliver.

SOLUTIONS Dynamic specializes in

We design coordinated power systems with inrush control, clean distribution, and rock‑solid protection. We also provide follow‑up design reviews and feed field learnings back to manufacturers for continuous improvement.

Machine Intelligence & Control →

Smart machines rely on unified logic, motion, and safety. We architect scalable, programmable control systems, and our hands‑on training sessions empower your team to adapt them as requirements evolve.

We enable fast, secure communication across the factory floor. From managed switches to IIoT gateways, our solutions include protocol‑specific workshops that maintain throughput and data integrity.

Integrated Control Solutions →

We partner with OEMs and machine builders to deliver high-volume, application-specific control systems. Our guidance helps engineers make informed design choices that improve production.

From IP‑rated connectors to vibration‑proof cable glands, we help you wire smarter—labeled, routed, and built for uptime. Our installation workshops have reduced field failures by 90%.

Thermal Control & Enclosure Protection →

We design for heat, humidity, vibration, and ingress protection, with tested enclosures and hands-on guidance to keep controls cool and clean.

Industries we serve

We apply system‑level expertise to build reliable machines across sectors—from precision automation in advanced manufacturing and compliant architectures in life sciences to rugged controls for agriculture, transit, and energy infrastructure. Whether it’s high‑speed robotics, mission‑critical data centers, or vibration‑tolerant field gear, our deep industry knowledge ensures uptime, scalability, and regulatory confidence in every environment.

Advanced Manufacturing & Industrial Automation

Smarter integration for robotics, motion systems, and production equipment.

We support OEMs, semiconductor toolmakers, and packaging automation engineers.

Energy & Infrastructure

Scalable control and power solutions for mission-critical uptime.

We support fuel cell developers, data center contractors, and manufacturers of grid-integrated equipment.

Transportation & Mobility

Vibration-tested, future-ready control solutions for evolving transport tech.

We support railway OEMs, EVSE developers, and transit infrastructure teams.

Agriculture & Heavy Industries

Tough, field-proven solutions for rugged and remote environments.

We support ag-tech equipment builders, mining automation teams, and heavy system OEMs.

Life Science & Process Industries

Clean, compliant, and precise control architectures for regulated environments.

We support lab automation OEMs, biotech manufacturers, and pharmaceutical systems integrators.

Other Industries

We support engineers from all industries in completing their projects with high-quality parts and trusted expertise.

Learn more about other industry-specific engineers that Dynamic has delivered success for.

Why engineers choose dynamic

You’re not just buying parts. You’re building machines.

We ask better questions. We show up when it counts. And we help you build machines that deliver.

Your systems are designed to operate as one coordinated whole, so every part of the machine communicates clearly and performs reliably from the very first start-up.

Encouraging conscious engineering decisions and improving manufacturability by reducing production complexity.

Every recommendation is driven by your performance goals, with components from multiple manufacturers selected to integrate smoothly and deliver dependable operation.

We engineer for fast, trouble-free installation, reducing rework and downtime while ensuring machines run reliably long after they leave the production floor.

Let’s Build Better Systems Together

Dynamic helps OEMs and integrators design reliable machines, reduce rework, and launch faster with lower risk.