Industrial Connectivity Built for Real-World Machines

Connect machines, extract data, and enable smart automation without overhauling control systems.

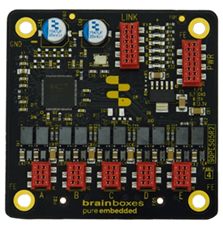

Brainboxes industrial communication hardware bridges the gap between legacy equipment and modern data systems ... so you can reduce downtime, improve visibility, and unlock actionable insights across any operation.

Industrial Data Access Without Redesigning Control Systems

Solve visibility, diagnostics, and monitoring challenges without PLC rewrites or production disruption.

Brainboxes provides industrial communication hardware that creates a clean data layer alongside existing machines, connecting legacy and modern equipment into reliable data pathways.

When Engineers Come Here, It Is Usually Because…

You need data from machines that were never designed to share it:

- Legacy PLCs, serial devices, isolated sensors

You cannot risk modifying validated or production-critical control systems:

- Certification, uptime, safety, or operational risk

You want monitoring, diagnostics, or production insight now:

- Not a complete redesign or capital project

A Dedicated Data Layer for Industrial Systems

Brainboxes devices sit outside the core control logic and act as a dedicated data pathway. They collect signals, translate protocols, and move information to higher-level systems without interfering with machine operation.

-

Non-intrusive data collection

-

Industrial-rated networking and I/O

-

Legacy and modern protocol support

-

Designed for long service life and continuous operation

PRODUCTS

Engineers typically deploy Brainboxes in one of the following scenarios.

WHY ENGINEERS WORK WITH DYNAMIC

Brainboxes makes the hardware. Dynamic helps you apply it correctly.

Additonal Insights

Predictive maintenance is no longer a future ideal — it’s becoming a baseline requirement for smart factories. By detecting machine issues before...

Read More

If your machines still run, why replace them? That’s the mindset a lot of OEMs, controls engineers, and industrial designers hold — and for good...

Read More

Machines don’t call in sick—but harsh conditions can knock them offline.Extreme heat, vibration, humidity, dust, and electromagnetic noise can...

Read More

In today's interconnected world, industrial networks ensure seamless communication and operation within manufacturing facilities. These networks...

Read More