Predictive maintenance is no longer a future ideal — it’s becoming a baseline requirement for smart factories. By detecting machine issues before they cause failure, predictive systems reduce unplanned downtime, extend asset life, and optimize labor and maintenance schedules.

But effective predictive maintenance doesn’t start with AI. It starts with reliable data; collected in real-time, from the edge of the machine to the cloud. That’s where industrial networking hardware plays a foundational role.

At Dynamic, we work with machine builders and OEMs who are deploying smart systems powered by real-time diagnostics, edge processing, and cloud analytics. The networking components we provide, especially from partners like Brainboxes, help ensure those systems deliver clean, usable data that AI tools can trust.

Why Networking Matters for Predictive Maintenance

The performance of AI-powered predictive maintenance hinges on three things:

-

Timely data from connected sensors and control systems

-

Reliable communication across the facility; even in harsh conditions

-

Scalable infrastructure that integrates legacy and modern equipment

Without a strong data backbone, your AI tools are guessing. And in industrial environments, guessing leads to downtime.

How Brainboxes Products Support Smarter Maintenance

🧠 Remote I/O Modules = Smarter Sensor Integration

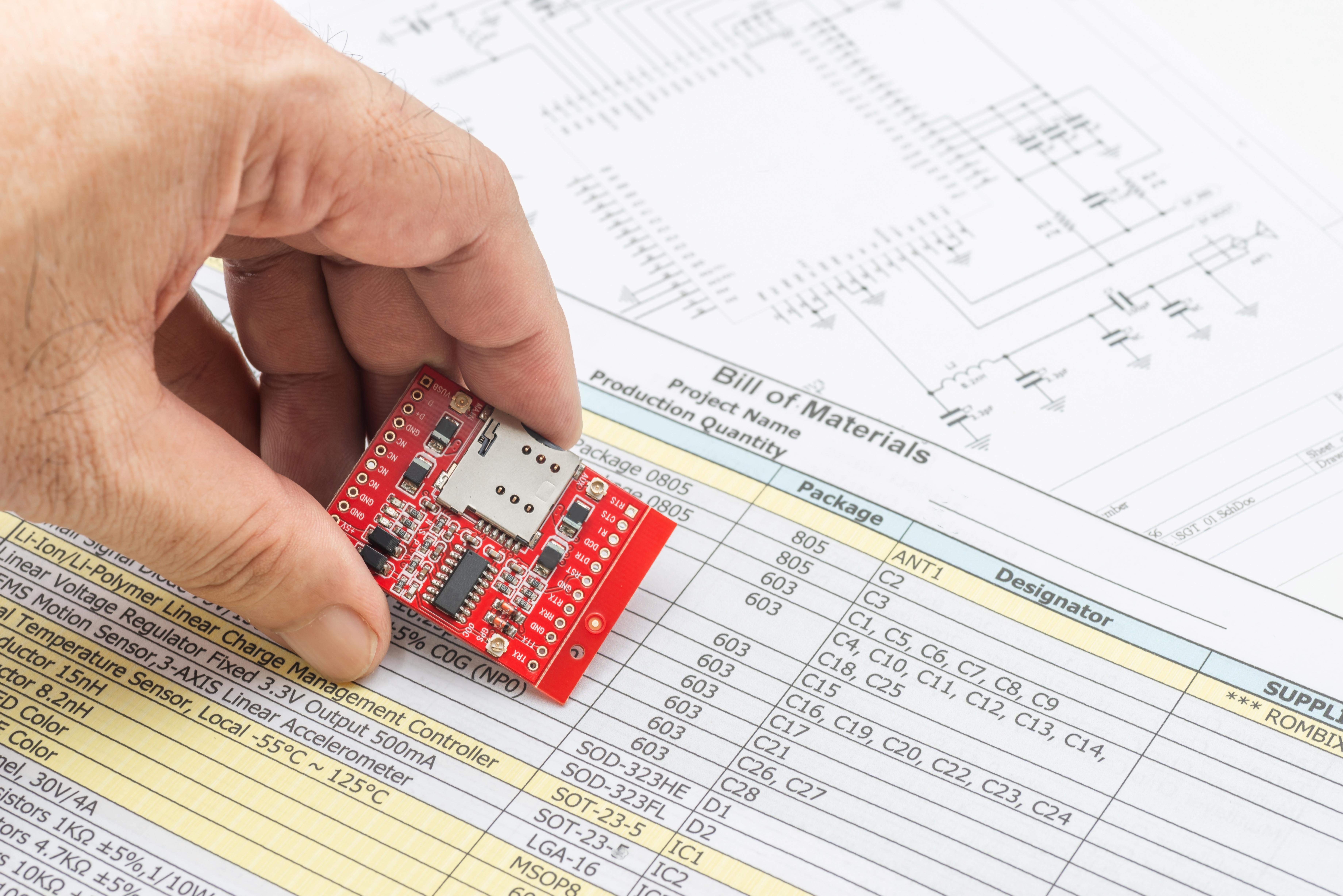

Predictive maintenance depends on sensor data; vibration, temperature, voltage, current, and more. Brainboxes Remote I/O Modules help bring that data online:

-

Support for analog and digital inputs/outputs

-

Quick installation via DIN-rail mounting

-

Options with temperature monitoring and environmental sensing

These modules capture the signals machines give off before something fails, and feed that data into local systems or cloud analytics platforms.

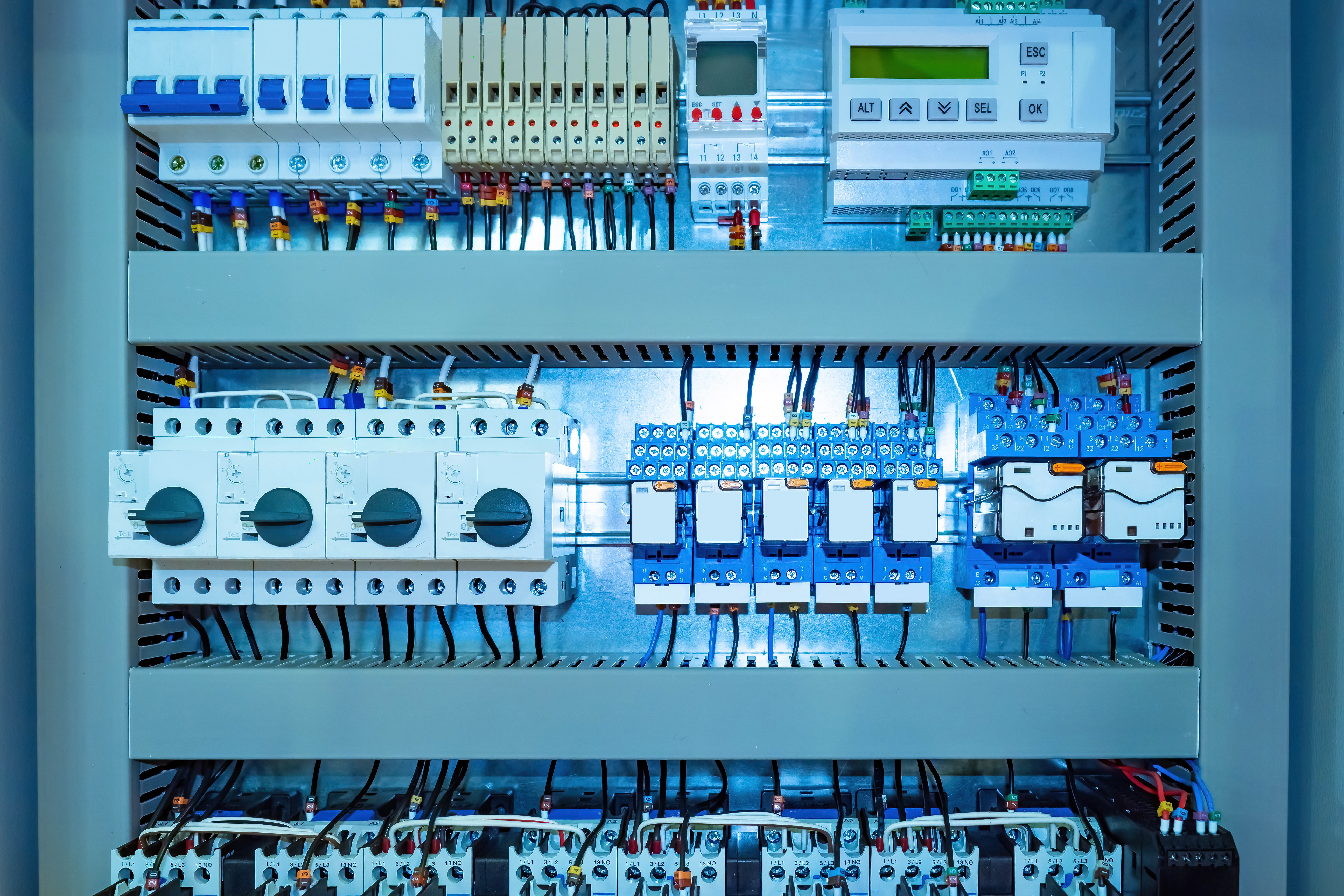

🔗 Industrial Ethernet Switches = Stable Data Flow from Edge to Cloud

Data bottlenecks or dropped packets can compromise predictions. Brainboxes Industrial Ethernet Switches deliver consistent uptime and fast data transfer, with:

-

Gigabit-speed performance for sensor-dense environments

-

PoE options to reduce cabling and simplify installs

-

DIN-rail-mountable, wide-temperature-range hardware built for factory floors

Reliable switches ensure that your edge devices, PLCs, and monitoring software stay connected and synced; even during high-load conditions.

🔄 Ethernet to Serial Adapters = Extending Predictive Capabilities to Legacy Equipment

Predictive maintenance doesn’t only apply to new machines. Brainboxes Ethernet-to-Serial Adapters allow older systems with RS-232/RS-485 interfaces to join the network:

-

Seamless integration into modern Ethernet or cloud-connected systems

-

Remote access and real-time diagnostics on equipment never designed for it

-

Ruggedized hardware that works in noisy, vibration-heavy locations

Now your older assets can talk and your AI systems can learn from them.

Building an AI-Ready Infrastructure

While AI models and predictive software get most of the spotlight, the real power lies in the data pipeline beneath them. The infrastructure you put in place today, the switches, I/O modules, and adapters, directly influences the quality and timeliness of the insights tomorrow.

That’s why factory and machine designers are increasingly focused on data architecture, not just component specs. With a solid foundation, you can:

-

Catch anomalies before they become breakdowns

-

Create service schedules based on real-world performance, not assumptions

-

Monitor energy consumption, wear patterns, and cycle trends in real-time

-

Tie together legacy machines and new installations into one smart system

Where Dynamic Fits In

At Dynamic, we support machine builders and OEMs building the next generation of factory intelligence. We help teams choose the right networking devices to support their predictive maintenance goals; whether that’s gathering better data, integrating old equipment, or scaling a smart system across multiple machines.

We’ve seen firsthand how smart networking can reduce downtime and shift maintenance from reactive to proactive; without adding unnecessary complexity.

Learn More About Networking for Predictive Maintenance

Looking to future-proof your system or start small with a pilot project? We’ve got the tools and technical insight to help.

Predictive maintenance starts with connected machines. We help you build the connections that power smarter decisions.