Enclosures & Thermal Management

Protect What Powers Your Machine

From control panel enclosures to precision thermal management, Dynamic helps engineers build safer, cooler, and more reliable systems.

Thermal management isn’t something you want to guess at. When you work with Dynamic, you get an experienced rep who helps you make the proper enclosure and cooling decisions upfront, saving you from costly heat-related failures later. Don’t risk your components or your timeline ... let’s get it right the first time.

Heat Is the Hidden Threat to Performance

Every 10°C rise in temp can halve component life

Overheating causes ~55% of system faliures

Poor airflow leads to nuisance trips and PLC resets

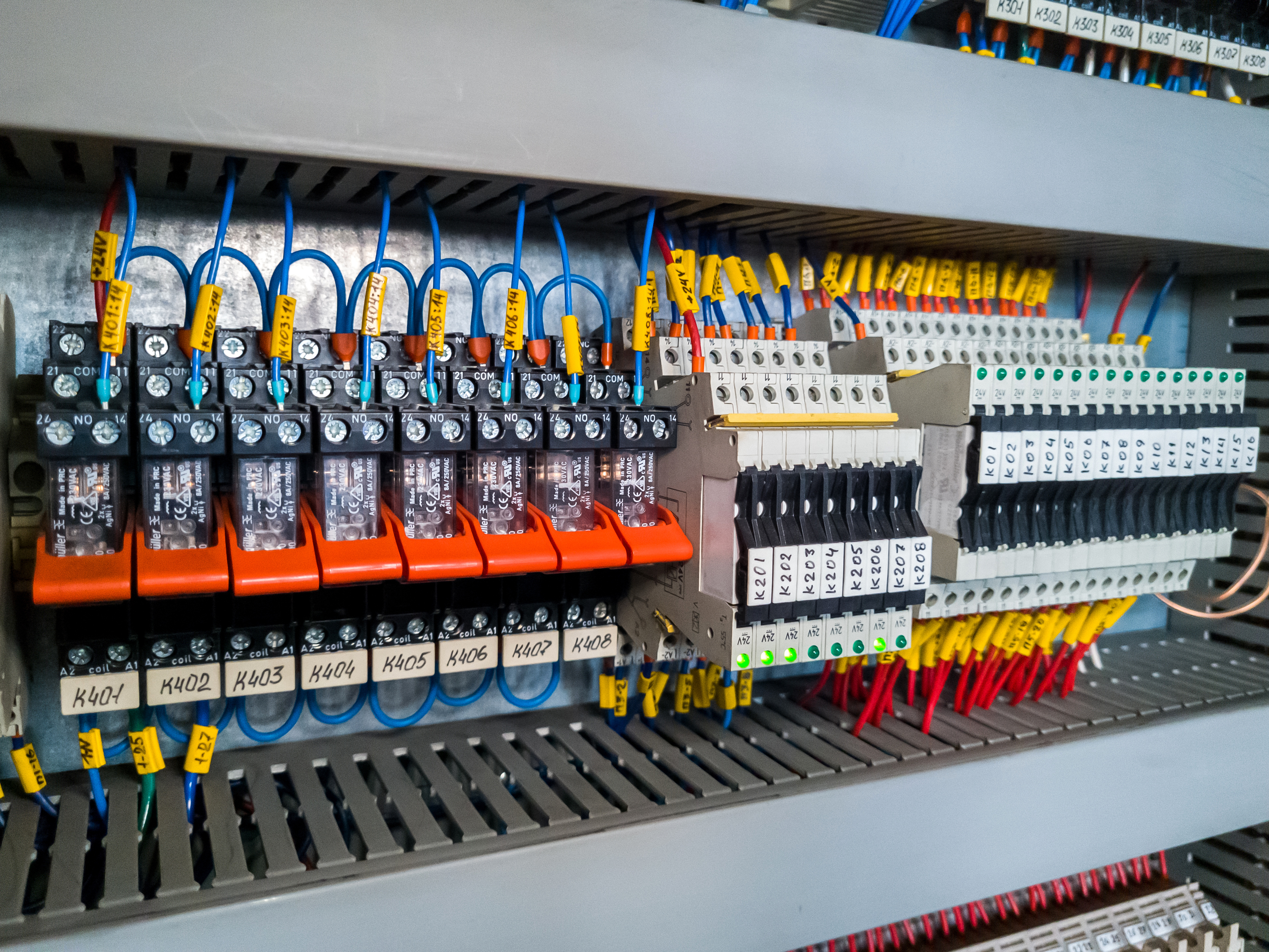

Enclosures Built for Real-World Engineering Needs

NEMA-rated enclosures

Custom mounting hardware

Thermal insulation materials

Panel interface ports & connectors

Fan trays, filters, and vent kits

Compact enclosure heaters and coolers

Hidden Heat Damage Can Wreck Performance

Fan trays and passive vents

Panel-mount or DIN-mount cooling units

Internal layout consultation to minimize trapped heat

Heat-dissipating gaskets, interface pads & thermal bridges

Component mounting strategies for better heat sinking

Our Engineering Insight = Your System's Reliability

Semiconductor Tooling: Preventing EMI-induced thermal cycling in high-density cabinets

Food Processing: Protecting VFDs and relays from steam + corrosion buildup

Renewables: Keeping outdoor combiner boxes within safe operating range

Data Centers: Designing compact control panels with low-noise heat extraction

Hot Enclosures? Cool Ideas? Coffee comes in both.

Smart thermal control isn’t just fans, it about protecting your build. Planning or fixing heat? Let’s talk.

We’ll review your project, share ideas, and guide smart choices; no pressure, just clear, helpful engineering advice.

Critical Products for Thermal Protection

Here are a few examples of the tools we use to help you get the job done

(NEMA/IP rated, size and material matched to environment and heat load)

✅ Protects against environmental hazards (dust, moisture, heat, washdown)

✅ Provides the foundation for passive or active thermal management

✅ Right-sizing prevents thermal buildup by allowing proper airflow or cooling

Typical problems solved:

-

Overheating due to undersized panels

-

Component failure from exposure (moisture, dust, chemicals)

-

Insufficient space for airflow or future expansion

(Simple airflow management without active cooling)

✅ Promotes natural convection inside the enclosure

✅ Keeps out contaminants while allowing heat to escape

✅ Low-cost, no-maintenance solution for moderate heat loads

Typical problems solved:

-

Hot spots around high-wattage components

-

Humidity buildup

-

Over-reliance on active cooling when not needed

(Fan trays, enclosure air conditioners, Peltier coolers, panel heaters)

✅ Controls internal temperature under high heat loads

✅ Prevents condensation in cold or humid environments

✅ Maintains stable conditions for sensitive electronics

Typical problems solved:

-

High ambient temperature + heat-generating loads

-

PLCs or VFDs shut down due to thermal thresholds

-

Electronics are degrading from condensation during cold starts

(Gap fillers, insulating gaskets, thermal pads)

✅ Improves heat dissipation from critical components

✅ Reduces micro hot spots inside dense assemblies

✅ Enhances panel sealing while allowing thermal transfer

Typical problems solved:

-

Component hot spots that ventilation alone can’t fix

-

Premature sensor drift, relay chatter, or module resets

-

Maintaining NEMA/IP integrity while managing heat

Support That Starts with the Application, Not the Catalog

How we help:

- Thermal guidance based on actual load and enclosure layout

- Help avoid nuisance trips and unexplained shutdowns

- Application-driven mounting and airflow strategies

- Fast response, clear answers, and follow-through after the install

We also consult on design strategies:

- Using thermal interface materials to eliminate micro air gaps

- Designing for convection paths instead of relying only on active cooling

- Separating high-heat components from signal or sensor wiring

We Don’t Just Rep Products — We Help You Get It Right the First Time

Thermal issues don’t always announce themselves; sometimes it’s a phantom trip, a sensor that starts drifting, or a panel that runs hotter than you expected. When you work with Dynamic, you're not just choosing hardware — you're gaining a technical partner who helps you avoid the silent problems that can derail a project or damage your reputation.

We bring decades of experience helping engineers like you plan smarter, install cleaner, and protect the components that keep your machines running. Whether you're building a new system or fixing something that shouldn’t have failed, we’ll meet you where you are and help you confidently move forward.

Let’s solve it together ... before heat becomes your hidden enemy.