Are you considering using a Solid State Relay for your machine building but don’t know how? Do you have questions on Solid State Relays best practices?

In less than 10 minutes, you will get answers to frequently asked questions about SSRs like:

- What are SSRs

- What are they used for?

- When do you need a Solid State Relay?

- How do you know which one is best for you?

- ... and finally ... After getting the best SSR for your machine, how do you install it?

What are Solid State Relays?

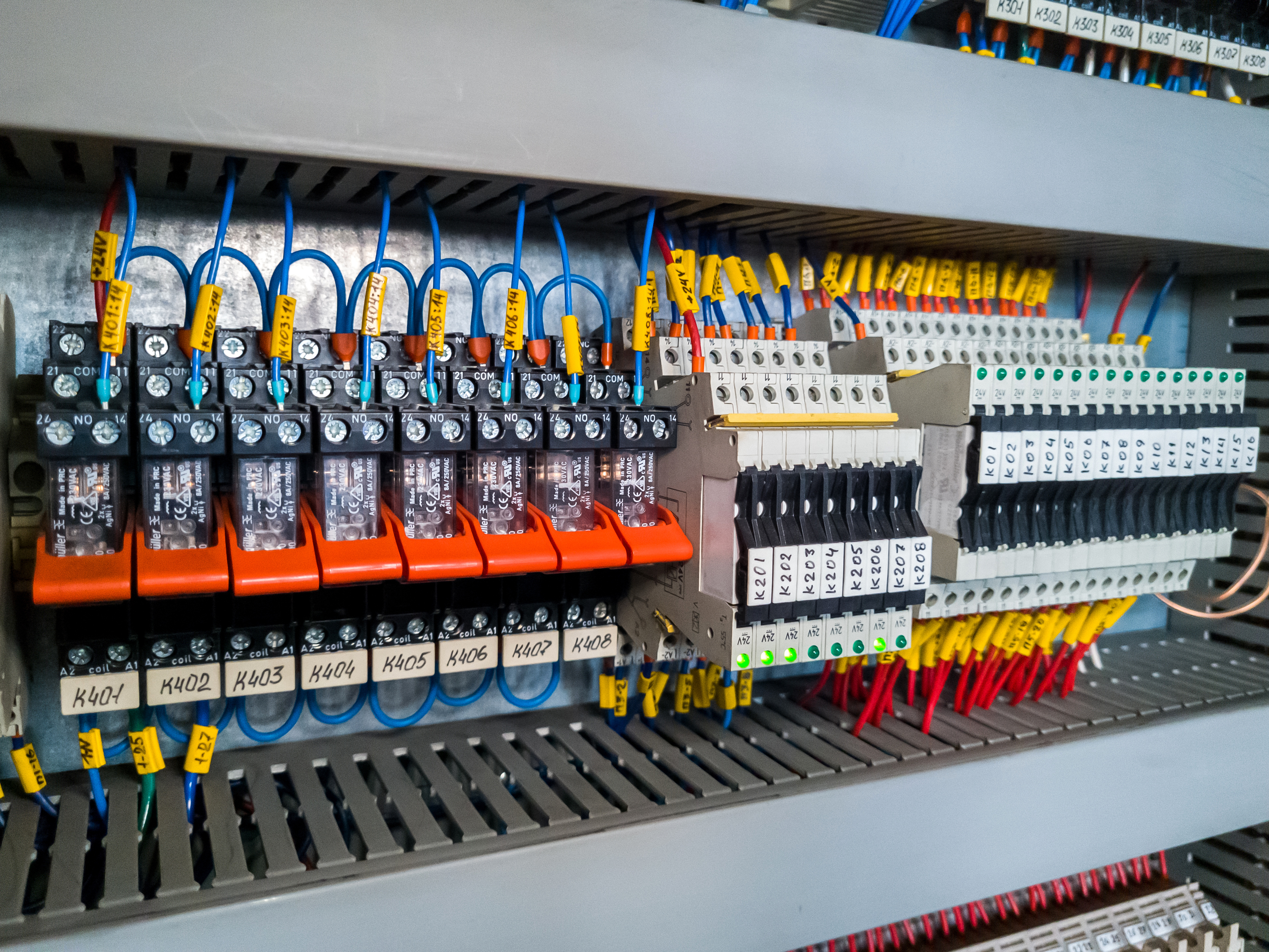

Solid-State Relays are electronic switching devices that switch on and off when an external voltage is applied across its input terminals.

Solid-State Relays are electronic switching devices that switch on and off when an external voltage is applied across its input terminals.

These Solid State Relays can be seen as the semiconductor equivalents of the electromechanical relays, and this makes them applicable for controlling electrical loads. Although SSRs are fairly complex devices, the purpose behind their design is simple – and that is to activate a single output load when energized.

What are Solid State Relays used for?

Solid State Relays have diverse applications across many industries, but for the purpose of this blog, we will focus on their applications based on their usage - electrical load control. We will also cover the three basic types of electrical load applications in which solid-state relays are most employed: heating elements, motor starting, and lighting.

Heating loads: Because of SSRs’ high-precision enablement and high-frequency temperature control, they are employed in heating elements applications such as infrared heating, residential heating, soldering equipment, thermoforming, commercial food processing machines, plastic injection molding/extrusion, HVAC, furnaces, among others. These heating elements have resistive loads, and a resistive load has no current in rush. In fact, you will find that most solid-state relays are used jointly with a pulse-voltage-output within the temperature controller for on/off heater switching. This application is ideal for an SSR because the switch-on function can be done immediately or at a time when the voltage is low (zero-cross) which suppresses the switching and common mode noise that is generated while switching. In addition to this, the SSR will not turn off immediately when the incoming signal goes low, but will switch off when the load current is reduced to almost zero (which is ideal for phase control).

Motor starting: Safe on and off switching is enabled by SSRs with zero crossing detection, as they are able to maintain their state until the AC output waveform crosses zero on its own. For this reason, Solid State Relays find applications in electric motors, which are inductive loads. However, inductive loads cause a large transient voltage spike when your relay is turned off because the magnetic field surrounding the inductive load collapses. Additionally, switching a relay during a peak in the mains voltage causes an electric arc between the relay terminals and wears them down, contributing to the mechanical failure of the relay. Both of which are rough and damaging conditions for electro-mechanical type relays. SSR's have an advantage for motor control because they have built in over-voltage protection, keeps the size of peripheral devices down (space savings), can de used to reverse motors and as soft starters (prolong motor lifetime). Motor control applications in which SSRs are employed include conveyor systems, pumps, compressors, elevators, fans, lifts, and hoists.

Lighting: Incandescent lamps, halogen lamps, and similar devices have a large inrush currents that are approximately 10 to 15 times higher than the rated current flowing through them. Using a Solid State Relay for these devices will ensure that the peak value of the inrush current does not exceed half of the inrush current resistance of the SSR. Lighting applications for solid state relays include airport runways, municipalities, theaters, office spaces, and roadways.

When do you need a Solid State Relay?

When your machine or electrical device requires high-speed and frequent switching, Solid State Relays are your best option. Likewise, if you want a quiet operation with minimum EMI noise, as well as an extended operational life, you need a Solid State Relay.

How do you know which SSR is best for you?

As we have discussed earlier, Solid State Relays have a wide range of applications. Knowing which one is best for your application or even selecting the right one can be confusing. So, we have designed this easy and simple to use exercise that will serve as pointers for selecting the correct Solid State Relay for your equipment.

Step 1: Estimate your load voltage and current

Step 2: What control voltage or input signal will be needed to turn on your SSR?

Step 3: How many poles will you be switching?

Step 4: Is your load resistive, inductive or capacitive?

Step 5: Is your mounting style a Panel or Din-Rail mount?

Step 6: Measure the ambient temperature

Once you have all these steps mapped out, the best solid state relay for your electrical device will be staring you right in the face. If you need assistance doing this, click here to get expert help.

You have the perfect Solid State Relay. Now, what?

Already laid hold of your Solid State Relay? Fantastic! The next thing for you to do is install it. Use this simple technique that we’ve designed, called “The quick 6” to install your Solid State Relays for optimal performance.

- Mount your SSR on a heat sink and make sure it’s properly fixed. This will allow the Solid State Relay to operate at a nominal current.

- Use a clean, flat and smooth thermal interface for proper heat regulation. For three-phase applications, we recommend using a thermal grease as the thermal pad will have limited power dissipation.

- Avoid mounting your SSR on plastic or painted surfaces as this will hinder its performances.

- Screw your tightening torque terminal between 1,2 and 1,8 NM maximum, and preferably use an electric-powered screwdriver while doing this. Your screwing speed should not go beyond 250 rpm. Avoid using any tool that is related to gas, wind, or air to prevent electric shocks.

- Orient the heatsink fins vertically to ease convection. With this orientation, a sufficient clearance of minimum 1x heatsink width should be available around the SSR for proper air circulation.

- If you have a limited space, then use horizontal fixing of the heatsink with a fan. In the absence of a fan, set the nominal current to derate by 30%. Also, there should be no space between two SSRs in confined spaces, and forced cooling from either a fan or air conditioning inside the cabinet will significantly improve the thermal performances.

TL; DR

In too much hurry to read all? Here's a summary:

- Solid State Relays are electronic switching devices that switch on and off when an external voltage is applied across its terminals.

- Solid State Relays have diverse applications, but are majorly used for load controls. The types of loads controlled by Solid State Relays include heating loads, motor loads and lighting.

- If you want a quiet operation and minimum EMI noise, as well as an extended operational life, you need a Solid State Relay.

- To know or select the right Solid State Relay for your electrical devices, you will need to estimate your load current/voltage, calculate the control voltage/input signal, identify the number of poles you’ll be switching, determine your load type (resistive, inductive or capacitive), decide whether to use a Panel or Din-Rail mounting style and finally, measure the ambient temperature.

- To install your Solid State Relay for optimal performances, use “the quick 6”.

If you find our blog on Installing Your Solid State Relays useful, you may also love to see the Advantages of Solid State Relays over Electromechanical Relays. We would love to have you join other machine and electrical control panel builders on LinkedIn where we share insights and stories that are helping our engineers build awesome products and manufacturers get these products to the market faster.

Check out our Solid State Relays for your machine

Should you need help in any way for your Solid State Relays or other electrical control components, feel free to reach out to us.