In the era of IIoT and Industry 4.0, solid-state relays (SSRs) have become an essential component for various industrial applications. These devices are known for their reliability, efficiency, and precise temperature control. With the integration of Fieldbus interfaces, SSRs have evolved to offer real-time monitoring, diagnostics, and communication capabilities, making them a game-changer in the world of automation. This blog will explore the features, benefits, and applications of solid-state relays with Fieldbus, exploring how they have revolutionized industrial automation.

Introduction to Solid-State Relays

Solid state relays are electronic switching devices that control high current loads using low voltage input signals. Unlike electromechanical relays, SSRs have no moving parts, which makes them more reliable and long-lasting. As a result, they are widely used in various industries to control power, temperature, and other critical parameters.

Advantages of Solid-State Relays

SSRs offer numerous advantages over traditional electromechanical relays, including:

- Longer lifespan due to the absence of mechanical wear and tear

- Faster switching speeds

- Noise-free operation

- Lower power consumption

- Resistance to shock and vibration

These benefits make SSRs the preferred choice for many industrial applications, especially those requiring precise control and reliability.

Check out our SSRs for your project

The Evolution of SSRs: Integration of Fieldbus Interfaces

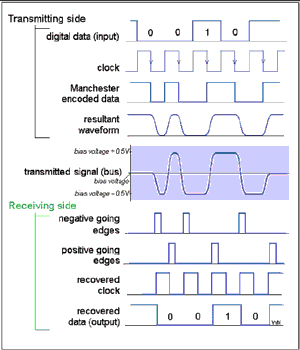

In recent years, SSRs have evolved to incorporate field bus interfaces, allowing them to communicate with other devices in an industrial automation system. In addition, Fieldbus interfaces enable real-time monitoring, diagnostics, and control, making SSR even more versatile and efficient.

Fieldbus Interface Types

Two popular fieldbus interface types for SSRs are:

- Modbus RTU: A widely used serial communication protocol that enables easy integration with building management systems (BMS) and industrial automation systems (IAS). Modbus RTU is known for its ease of use and reliability.

- Ethernet IP, Ethercat, Profinet: These advanced communication protocols can be used with SSRs through a Modbus RTU converter gateway, offering greater flexibility and compatibility with various industrial networks.

The integration of these communication interfaces has transformed SSRs into powerful tools for real-time monitoring and control in industrial applications.

Real-time Monitoring and Diagnostics

Solid state relays with field bus interfaces allow real-time monitoring and diagnostics, providing valuable insights into the performance of the relay and the connected load.

Load Status & Relay Diagnostics

SSRs with fieldbus interfaces can detect and diagnose various issues, such as:

- Loss of mains

- Loss of load

- Short circuit

- Overheating

- Relay out of set range

These diagnostic features help identify problems early, reduce downtime, and improve overall system performance.

Current Monitoring & Alarms

SSRs with fieldbus interfaces can monitor load current and trigger alarms when the current exceeds a predefined threshold. This feature helps prevent damage to the relay and the connected load while ensuring optimal performance.

PID Temperature Control

SSRs with fieldbus interfaces often come with built-in PID temperature controllers, enabling precise temperature control in various applications.

- Thermocouple Input: These SSRs support insulated inputs for thermocouples like type J, K, T, and E, allowing accurate temperature measurement and control.

- Heating and Cooling Control: Logic outputs of the SSR can be used for heating and cooling control, providing flexibility in temperature regulation.

- Automatic and Manual PID Tuning: SSRs with fieldbus interfaces offer both automatic and manual PID tuning options. Automatic tuning constantly analyzes the error between the setpoint and process value, adjusting the PID parameters accordingly. Manual tuning lets users decide when and how to update the PID algorithm parameters.

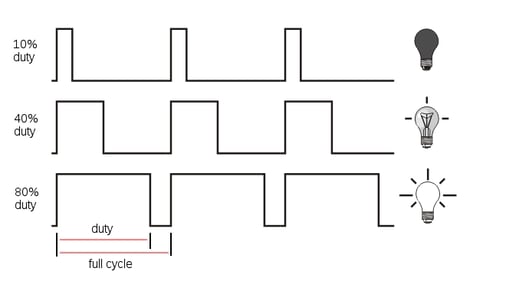

Pulse Width Modulation (PWM) Control

SSRs with fieldbus interfaces can also provide PWM control, a method of controlling the amount of power delivered to a load without wasting energy. PWM control allows users to set the duty cycle and cycle time via the communication interface, optimizing load power control.

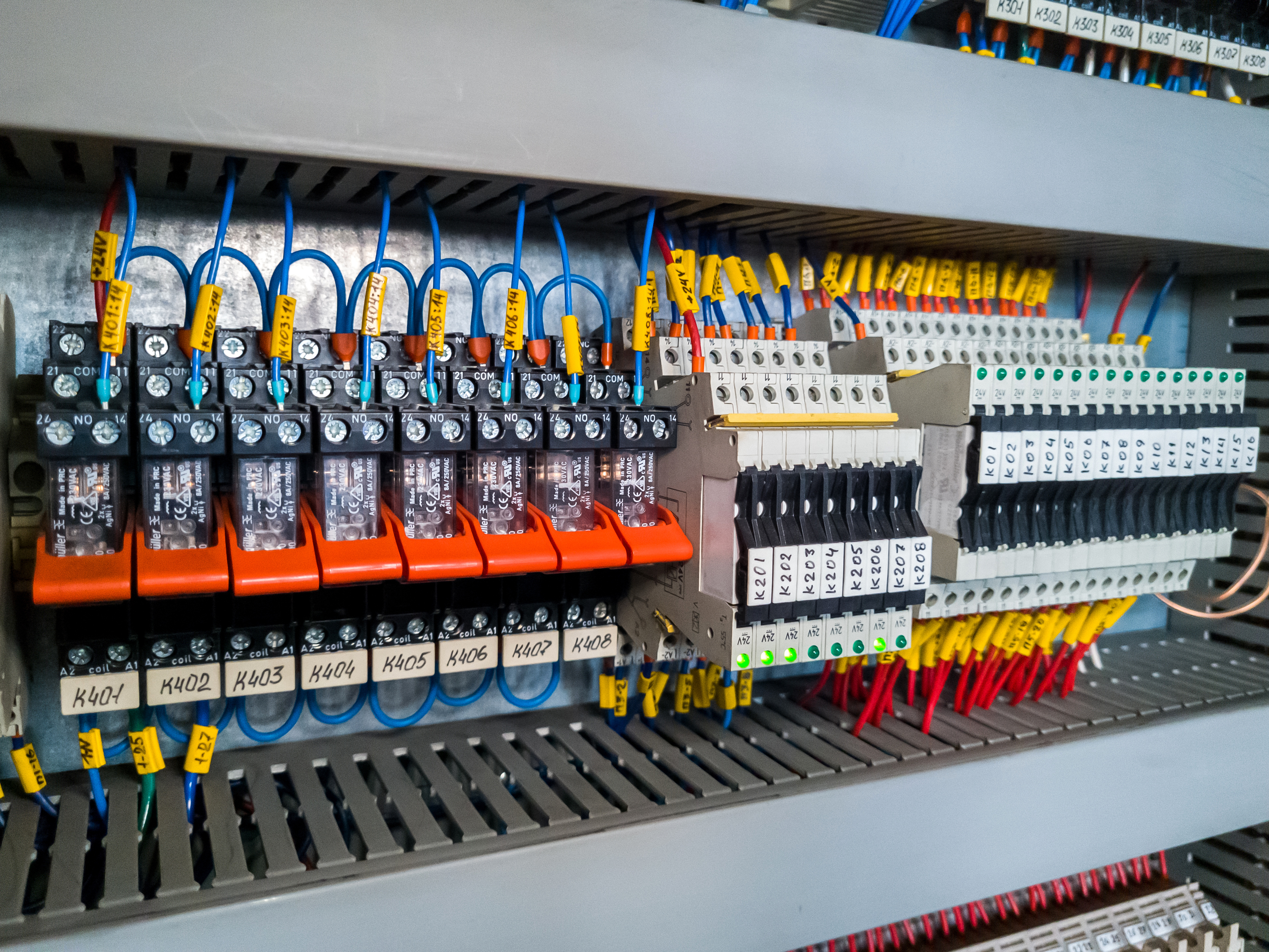

Compact and Efficient Solutions

SSRs with field bus interfaces are designed to be compact and efficient, reducing wiring costs and minimizing the size of electrical cabinets. In addition, these devices can be easily integrated into existing systems, offering a cost-effective solution for upgrading industrial automation networks.

Compatibility with HMI and PLC Systems

HMI or PLC systems can directly control solid state relays with fieldbus interfaces using Modbus RTU protocol, offering seamless integration with existing control systems.

Applications of SSRs with Fieldbus Interfaces

Solid state relays with field bus interfaces are ideal for various applications where safe and accurate temperature control is crucial. Some typical applications include:

- Plastic injection machines

- PET blow molding machines

- Semiconductor manufacturing

- Tempered glass machines

These devices provide real-time data access, enabling machine builders to develop more intelligent, autonomous machines that offer cost savings and increased performance.

Examples of Solid State Relays with Fieldbus Interface

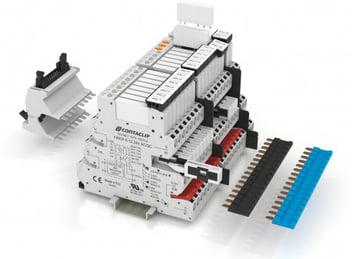

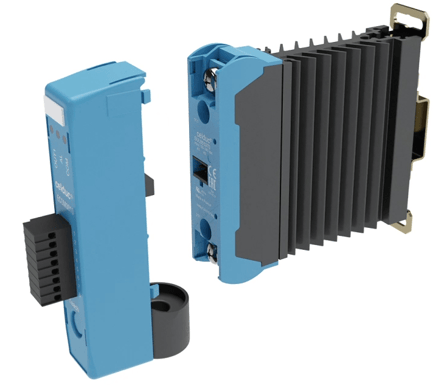

Below is an example of solid-state relays with Fieldbus interfaces, highlighting their features and benefits:

ECOM0010 and SU/SUL (Celduc Relays)

The ECOM0010, combined with SU/SUL, is a compact solution with a communication interface, current monitoring, and a PID temperature controller. It is the most compact solution available on the market, incorporating the latest measurement and control technology.

Conclusion

Solid state relays with field bus interfaces have revolutionized industrial automation by providing real-time monitoring, diagnostics, and communication capabilities. In addition, these devices offer a compact, efficient, and versatile solution for various applications, ensuring accurate temperature control and enhanced system performance. As the demand for smarter, more autonomous machines continues to grow, SSRs with field bus interfaces will play an increasingly important role in the future of industrial automation.

Check out our Solid State Relays for your project