How Machine Builders Can Stay Ahead When Space Shrinks but Data Grows

For years, we’ve been helping machine builders shrink control panels. Smaller enclosures. Fewer wires. Smarter layouts. All in the name of saving space, reducing cost, and streamlining production.

But here’s the twist: just as we’ve gotten really good at making compact panels, machines have started demanding a whole lot more data.

From predictive maintenance sensors and process control diagnostics to OT-level network requirements and IIoT devices sending real-time updates—data is coming from everywhere. And it’s not slowing down.

Now Engineers are facing a real design challenge:

How do you fit exponentially more functionality into a panel that keeps getting smaller?

Why This Matters

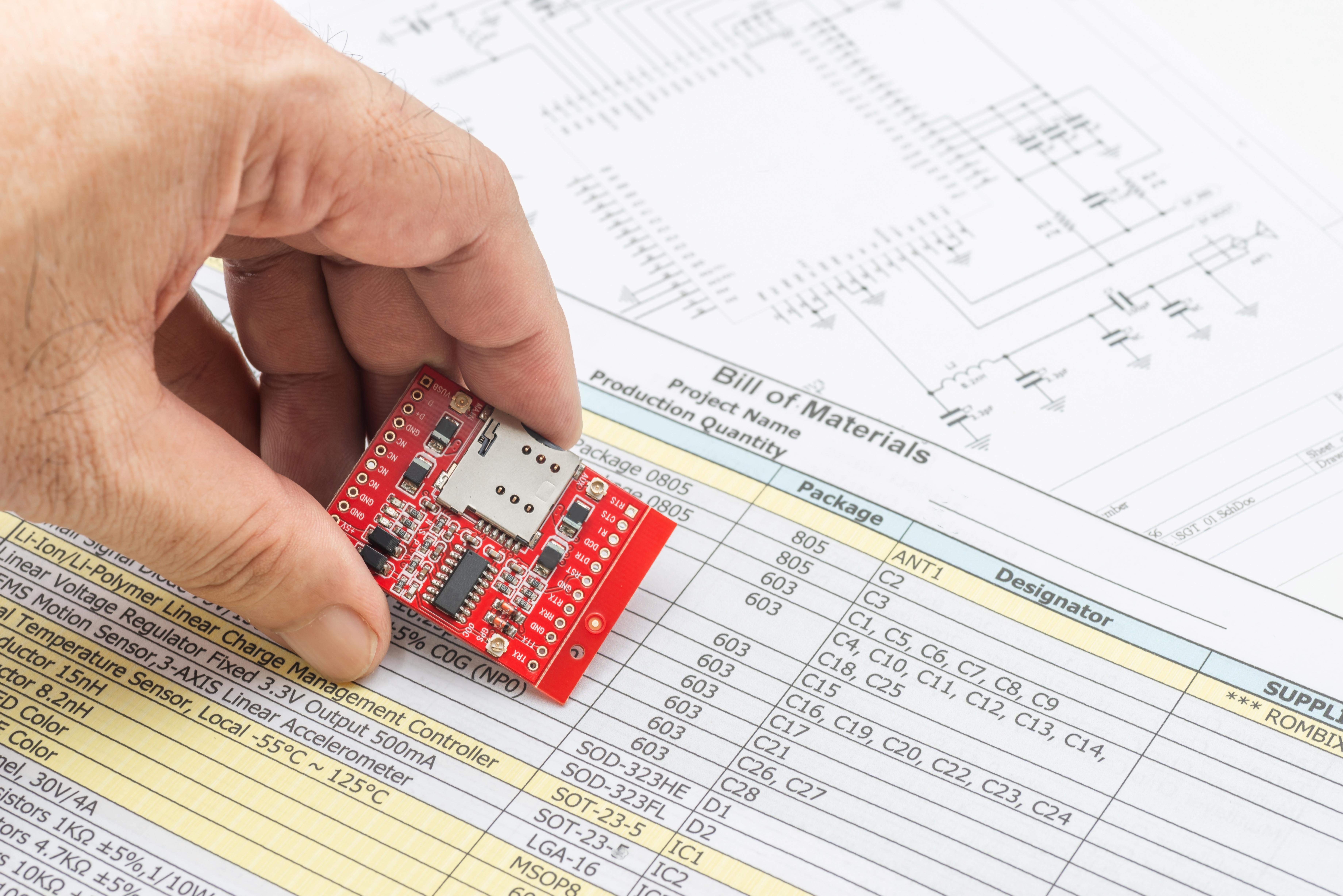

Control panels are no longer just boxes of relays and terminals. They’re digital communication hubs. Every signal is a chance to monitor performance, anticipate failure, or improve efficiency.

Machine builders are under pressure to offer more connected features. More feedback. More visibility. But with less room to work with.

If you’re running into that exact problem, you’re not alone. We’re hearing this from OEMs across nearly every industry. Shrinking machine frames. Demand for smarter control. Operators asking for more data access. And no one wants to give up cabinet space.

Practical Ways to Handle It

You don’t need to reinvent your entire architecture to keep up. Here are some design shifts that are helping teams we work with every day:

-

Use distributed I/O: Mount it on the machine instead of sending everything back to a central panel. You’ll reduce wiring, free up space, and simplify maintenance.

-

Standardize on Ethernet: Common protocols mean fewer gateways, less hardware, and better data visibility across devices.

-

Choose multi-functional components: Save DIN rail space by using devices that combine power, switching, or I/O functions.

-

Move select devices out of the panel: With the right IP ratings and vibration tolerance, some hardware belongs on the machine.

-

Design with service in mind: Compact doesn’t mean cramped. Plan layouts that allow room to troubleshoot and expand.

Where It’s Headed

Data isn’t going away. If anything, tomorrow’s machines will demand even more of it. That means the pressure to create smarter, smaller, more scalable panels is only going to increase.

Those who get ahead of this trend now will be the ones offering cleaner builds, faster installs, and longer lifecycle value to their customers.

How Dynamic Helps

At Dynamic, we’re in the trenches with OEMs on these challenges every day. We bring solutions for smarter space usage, high-density control layouts, and rugged connectivity that helps your data move faster without making your cabinet bigger.

Whether it’s through modular I/O, space-saving power components, or helping you rethink enclosure strategy altogether, we’re here to be your design resource, not just your product source.

Need help balancing your data demands with real-world panel constraints? Let’s talk. We’ll help you build something scalable, smart, and ready for whatever the next machine demands.

→ Reach out to the DynamicRep team and let’s build better, together.