If your machines still run, why replace them? That’s the mindset a lot of OEMs, controls engineers, and industrial designers hold — and for good reason. Legacy systems were built to last. But in a world where everything talks to everything, keeping those systems connected has become a challenge.

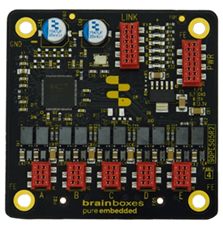

At Dynamic, we specialize in helping machine builders modernize without starting from scratch. With solutions from partners like Brainboxes, we make it easy to bring older equipment into today’s connected industrial environment.

What’s the Real Issue with Legacy Systems?

Legacy machines aren’t the problem. The problem is what they can’t do:

-

No real-time visibility or remote access

-

No way to scale or integrate with new systems

-

No simple path for diagnostics or predictive maintenance

These systems often rely on outdated serial communications or standalone control, which limits an operation’s flexibility and performance.

But here’s the good news: you don’t need to buy a new forklift. You just need smarter connectivity.

Smart Ways to Connect Old Tech to New Networks

Here’s how Brainboxes delivers practical, powerful solutions for industrial teams trying to modernize:

Ethernet to Serial Adapters

Outdated serial ports (RS-232/DB9) don’t cut it in IIoT environments. Brainboxes Ethernet to Serial Adapters let you:

-

Integrate legacy systems into Ethernet-based networks

-

Enable remote access and real-time data control

-

Avoid costly rewiring or system overhauls

This is how our clients in packaging machinery and legacy tool retrofit get modern performance without tearing up their floor plans.

Industrial Ethernet Switches

Rugged, DIN-rail mountable, and built for harsh environments — these switches are the backbone of a connected facility. With PoE and Gigabit options, you get:

-

Stable data flow and zero packet loss

-

Connectivity across multiple devices and system layers

-

Future-proofed network infrastructure

Need something scalable for machine control or high-speed data in tight spaces? These switches perform under pressure.

Remote I/O Modules

Add new sensors, controls, or monitoring points — even if your existing system was never designed for expansion. With support for analog/digital I/O and temperature monitoring, these modules:

-

Enable real-time remote diagnostics

-

Make distributed system design simple

-

Reduce on-site service needs

This is especially helpful in semiconductor, food processing, and outdoor infrastructure where data needs to move quickly and accurately across long distances.

Why Our Customers Use This Strategy

At Dynamic, we work directly with engineers who are under pressure to do more with less — faster. Here’s what you can gain by using connectivity solutions from Brainboxes:

-

✅ Extended system life without full replacements

-

✅ Increased uptime via real-time monitoring

-

✅ Simplified integration into existing control architectures

-

✅ Cost savings by avoiding unnecessary rebuilds

-

✅ Future-ready systems built to scale with minimal rework

You Know Your Machines. We Know How to Connect Them.

The industrial world is moving fast — and your machines need to keep up. Whether you're retrofitting legacy tools or building new systems with room to grow, we’re here to help.

Let’s talk about:

-

The right Ethernet switch for your environment

-

How to bridge serial to Ethernet without disruption

-

Smart I/O that grows with your system

👉 Visit our networking solutions page

👉 Explore Brainboxes devices

Or better yet, contact us directly — and get expert help from a partner who understands how machines are built and how they evolve.

Bridge the gap. Extend your system. Build smarter.

Work with Dynamic so you don’t have to choose between old and new — we'll help you connect both.