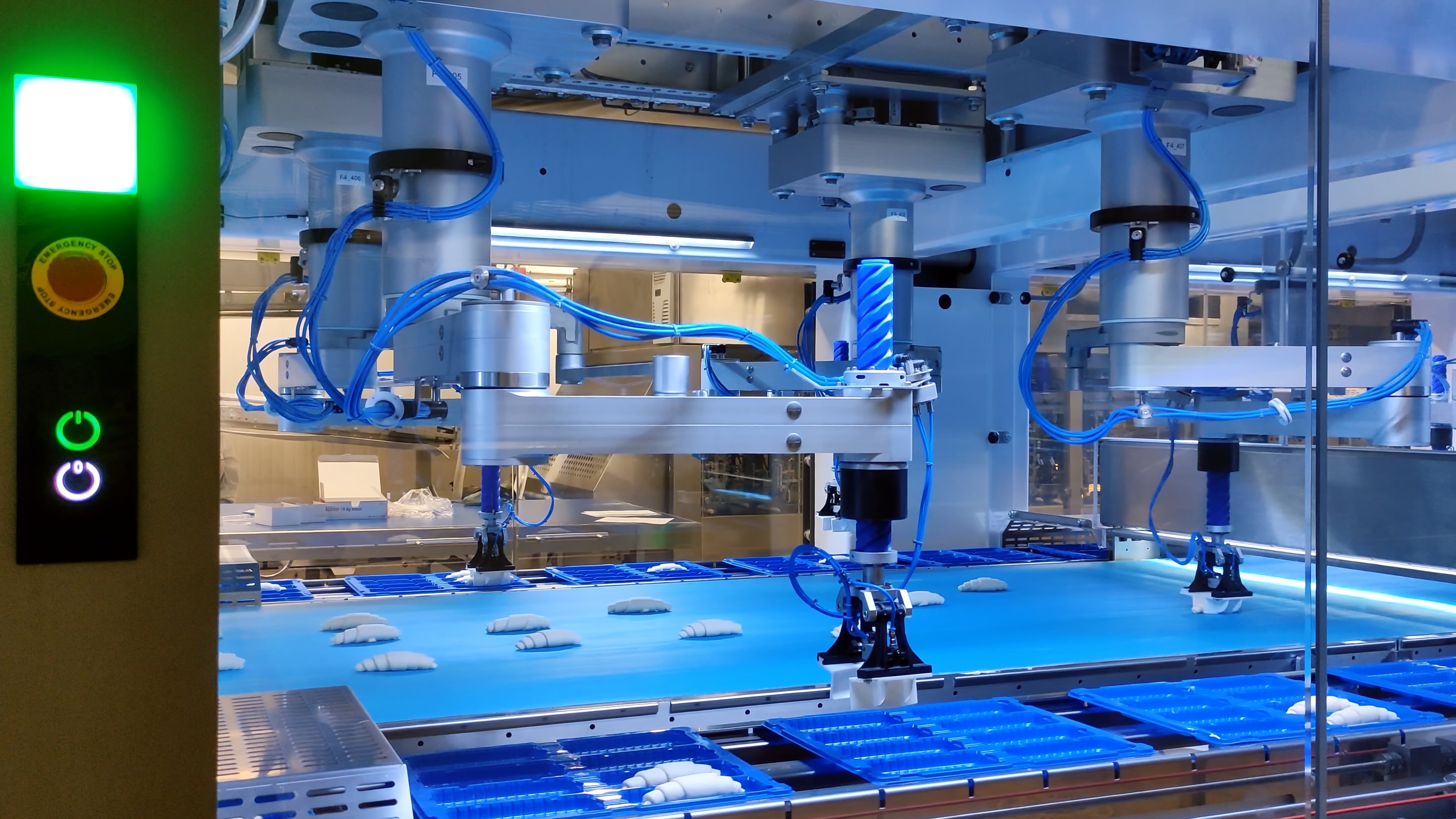

Industrial automation networks are the central nervous system of modern manufacturing. They connect controllers, sensors, and I/O devices across the factory floor, enabling the precise coordination required for high-performance systems. Increasingly, these networks rely on standard Ethernet and protocols like EtherNet/IP™ and PROFINET™, both governed and standardized by respected bodies such as ODVA for EtherNet/IP™ and the Common Industrial Protocol (CIP). This move toward open standards has changed the game for control system design.

With the rise of open Ethernet protocols, engineers are no longer locked into monolithic ecosystems and can now architect vendor-agnostic solutions using CIP-compliant hardware. Instead, you can integrate best-in-class components from various manufacturers, as long as they comply with CIP standards. This flexibility allows for more innovative, cost-effective, and resilient system architectures. However, it also introduces a new challenge: how do you ensure reliability when mixing and matching hardware?

The answer lies in choosing partners who not only embrace open standards but also build their products with industrial-grade toughness and back them with unwavering support. This is where Dynamic Measurement and Control Solutions and our partners excel. By integrating specialized industrial I/O modules and switches, you can de-risk your industrial Ethernet strategy and build truly future-proof machines.

The Power of Open Protocols and Rugged Hardware

The Common Industrial Protocol provides a universal language for industrial devices. It’s an object-oriented suite of messages that allows hardware from different vendors to communicate seamlessly over a standard Ethernet network. An Allen-Bradley PLC, for instance, can exchange data with a third-party I/O module just as easily as it can with its own brand's hardware. This interoperability is the foundation of modern, flexible automation.

We offer products designed around this open-network philosophy.  Our Remote I/O modules and Industrial Ethernet Switches are designed from the ground up to support common protocols such as Modbus/TCP and EtherNet/IP™, ensuring seamless integration with any modern control system. This means you can easily integrate them into existing PLC networks from major manufacturers such as Rockwell, Siemens, and Omron, treating them as standard remote I/O points.

Our Remote I/O modules and Industrial Ethernet Switches are designed from the ground up to support common protocols such as Modbus/TCP and EtherNet/IP™, ensuring seamless integration with any modern control system. This means you can easily integrate them into existing PLC networks from major manufacturers such as Rockwell, Siemens, and Omron, treating them as standard remote I/O points.

But compatibility is only part of the equation. Industrial environments are harsh. They involve electrical noise, temperature swings, and constant vibration. That's why we partner with manufacturers who engineer hardware specifically for these challenges.

Engineering to De-Risk Harsh Environments

The products we represent are not repurposed IT hardware; they are purpose-built for industrial applications. Key design features include:

- Wide Operating Temperature Range: From -40°C to +80°C, these devices perform reliably in unconditioned enclosures and extreme environments.

- Robust Power Inputs: Dual redundant power inputs (5–30 VDC) ensure continuous operation even if one power source fails.

- Electrical Protection: Every device features built-in protection against overloads, short circuits, and power surges. A 1500V isolation barrier between the I/O circuits and the Ethernet port prevents electrical noise from disrupting communication and protects sensitive equipment.

These features ensure that your network connectivity remains stable and your data integrity is never compromised. By specifying industrial-grade connectivity through DMCS, you proactively reduce system-level risk and align with engineering best practices for high-reliability design.![]() Whether you need an Industrial Edge Controller to manage data at the source or a robust Ethernet-to-Serial converter to connect legacy devices, we have a solution.

Whether you need an Industrial Edge Controller to manage data at the source or a robust Ethernet-to-Serial converter to connect legacy devices, we have a solution.

De-Risking Long-Term Ownership

One of the biggest concerns when specifying components from a third-party vendor is long-term support. What happens if a device fails years down the line? Who do you call for troubleshooting during a critical commissioning phase? This is where our partners truly set themselves apart and de-risk the decision for your engineering team.

The "Built for Life" Warranty

Our hardware partners offer a lifetime warranty on their products. If a device fails during its service life, it will be repaired or replaced at no charge. This is not a limited warranty with hidden clauses; it is a straightforward promise of quality and reliability. This level of commitment is exceptionally rare in the industrial hardware space and provides unparalleled peace of mind. It allows you to specify components with confidence that the manufacturer stands behind its product throughout its entire lifecycle.

"Connected for Life" Technical Support

In addition to the lifetime warranty, our partners provide free lifetime technical support. When you have a question about setup, integration, or troubleshooting, you get direct access to the same engineers who designed the product. There are no support tiers, service contracts, or call centers. You receive expert guidance from people who know the hardware inside and out.

This "Connected for Life" program provides your team with an on-call engineering resource dedicated to ensuring your I/O and networking components perform flawlessly. It removes the risk of being left without support and empowers your team to solve challenges quickly and efficiently.

How Dynamic Helps You Upgrade Your Approach

How We De-Risk Ethernet Decisions

- Open-Protocol Interoperability: Seamless integration with industry-leading CIP-compatible I/O and popular protocols like EtherNet/IP™.

- Lifetime Warranty Coverage: Hardware is backed by a straightforward “Built for Life” warranty.

- Free Lifetime Support: Access in-house engineers for direct and ongoing technical assistance, no service tiers or call centers.

- Rugged, Industrial-Grade Hardware: Engineered to withstand harsh environments, electrical noise, and temperature extremes.

- Application Engineering from DMCS: Benefit from expert guidance to ensure solutions fit your real-world system needs. At Dynamic Measurement and Control Solutions, we partner with manufacturers who share our commitment to system-level thinking and long-term reliability. Our partners' focus on open standards, rugged engineering, and lifetime support directly complements our goal of helping you build better, smarter machines.

With us, you gain access not just to components but to expert-curated, field-tested architectures, vendor-agnostic integration guidance, and solutions reviewed by engineers to meet real-world operating conditions.

By incorporating specialized industrial connectivity solutions like Analog and Digital remote I/O into your designs, you gain:

- Flexibility Without Vendor Lock-In: Freely mix and match components to create the optimal system for your application, knowing that the devices we provide will integrate seamlessly.

- Reduced Field Failures: Industrial-grade hardware designed for harsh environments results in fewer installation headaches and higher machine uptime.

- Lower Total Cost of Ownership: The combination of competitive pricing, a lifetime warranty, and free expert support significantly reduces the long-term cost of maintaining your systems.

- Confidence and Peace of Mind: You are not just buying a part; you are investing in a solution backed by two expert teams committed to your success.

When you work with DMCS to specify your industrial communication solutions, you leverage our application expertise and our partners' product excellence. We help you integrate these powerful components into a cohesive system, ensuring your machine’s data pathways are secure, reliable, and future-ready.