Connectivity

Connectivity directly contributes to design, functionality, and performance.

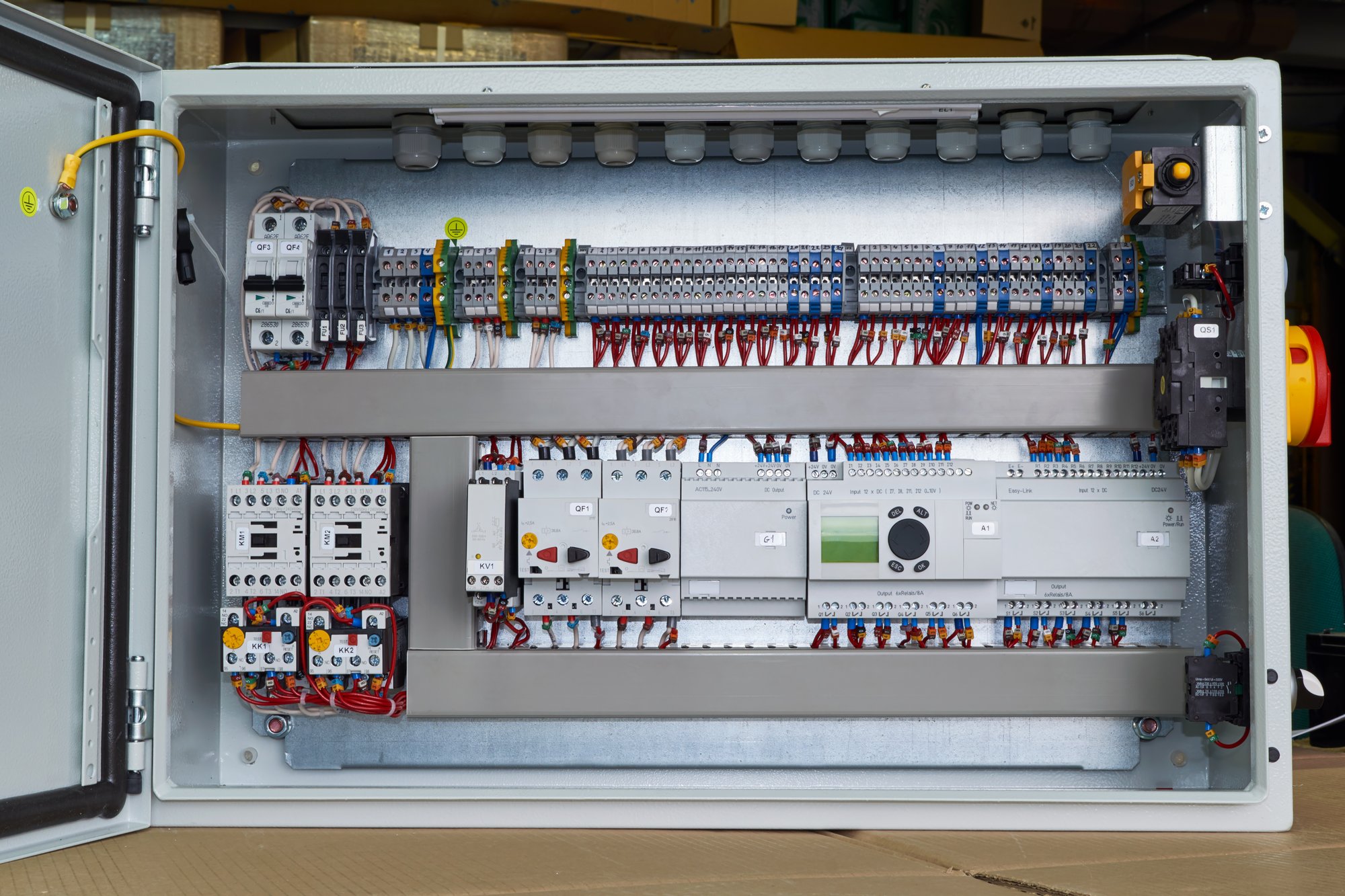

To design a machine well you must take a holistic approach where the selection and implementation of enclosures, connectors, wire termination, cable management, and considerations for space savings are all interdependent.

Each decision impacts the others and influences the machine’s functionality, safety, reliability, maintenance, and overall performance.

Dynamic can help you address these relationships during the design phase, we can help machine design engineers create sophisticated, efficient, and user-friendly machines that meet the demanding requirements of the production environment.

Integration and System Design

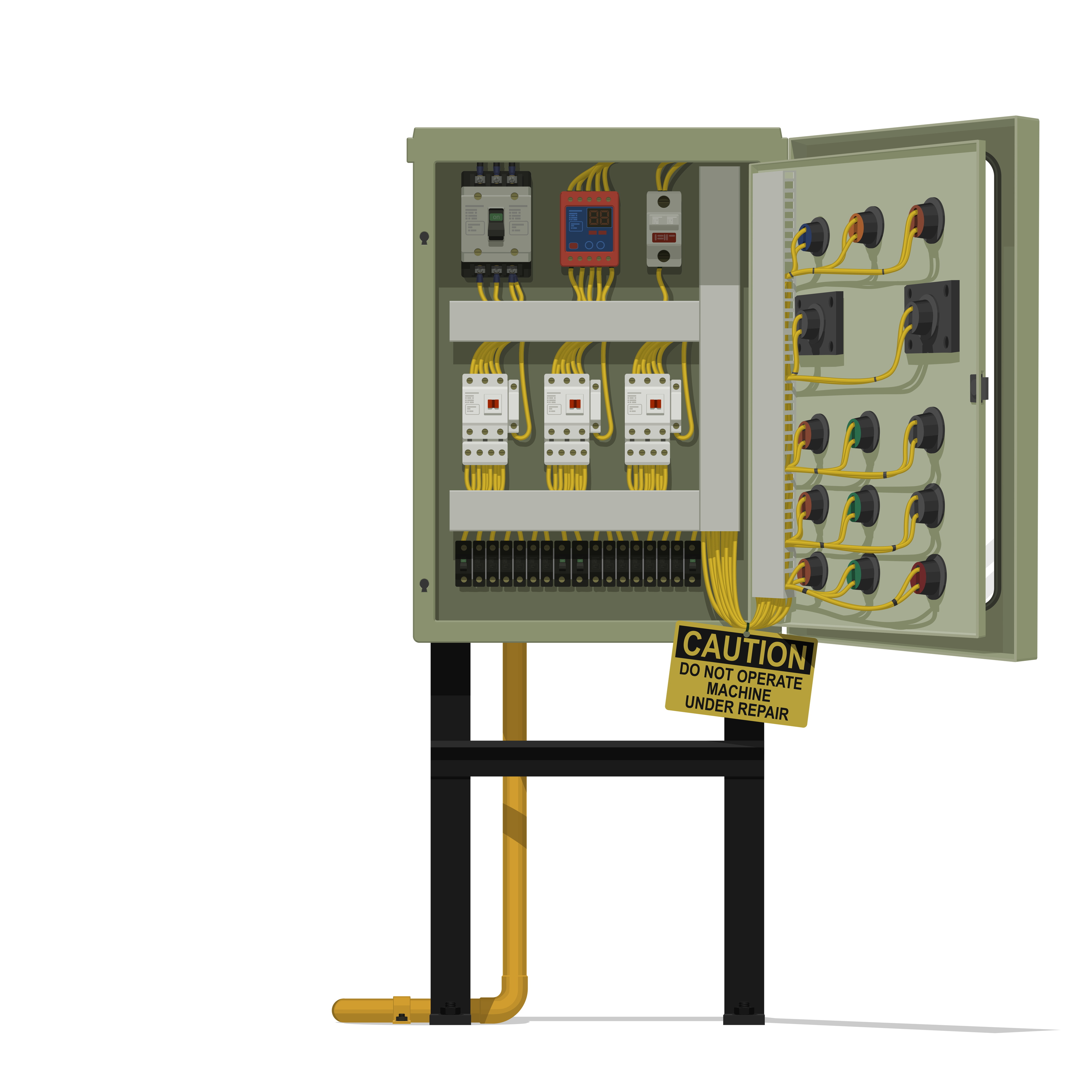

- Enclosures provide the physical housing for components and systems, determining the overall layout and space constraints within which connectors, wire terminations, and cable management must be accommodated.

- Connectors are chosen based on the requirements of the internal and external connections of the machine, including power, signal, and data connections that need to pass through the enclosure walls securely and efficiently.

- Wire termination techniques are selected to ensure reliable connections within the constraints of the enclosure, considering factors like space availability and the need to manage and route wires effectively.

- Cable management devices and strategies are influenced by the design of the enclosure, placement of connectors, and layout of the wires and cables requiring careful planning to optimize space, ensure accessibility, and maintain future organization.

Safety and Reliability

- The choice of enclosures impacts the protection of both the machine's components and its operators, necessitating designs that accommodate effective cable management and wire termination practices that uphold safety standards.

- Connectors must be compatible with the environmental ratings of the enclosures to maintain the integrity of the machine's protective measures against environmental factors.

- Proper wire termination and cable management are essential for preventing electrical failures and ensuring the reliability of connections, directly affecting the machine's operational safety and longevity.

Maintenance and Accessibility

- Enclosures must be designed with consideration for maintenance access, influencing the layout and accessibility of connectors and wire terminations.

- Cable management devices can make the maintenance personnel access, identification, and service a much easier job. Component locations within the machine will require thoughtful integration within the design.

- The selection and placement of connectors and the approach to wire termination play crucial roles in facilitating quick diagnostics and repairs, minimizing downtime.

Efficiency and Performance

- Space savings are a critical outcome of effective integration of enclosures, connectors, wire termination, and cable management, leading to more compact, efficient machine designs.

- The efficiency of a machine's design is enhanced by selecting enclosures and connectors that support optimal wire termination methods and cable management practices, ensuring that the machine can operate at peak performance without unnecessary bulk or complexity.

-

You can optimize industrial equipment costs by prioritizing certain factors. Making design decisions early based on a comprehensive understanding of machine design and manufacturing environments can lower costs in several areas for you and your end user.

-

Machine downtime can be attributed to various causes and failures, including electrical issues and the industrial control components. Understanding and addressing these potential failure points early on in the design are crucial for minimizing downtime and ensuring the reliability of industrial equipment.

-

This is perhaps the most critical aspect of industrial machine design is to ensure the well-being of personnel, protect assets, and maintain regulatory adherence.

-

Play a pivotal role in machine design by making it possible to control, monitor, regulate, and automate various processes.

-

By addressing these critical aspects during the design phase, industrial machinery will operate with high efficiency and precision, meeting the demands of modern manufacturing and contributing to the overall success of your industrial process equipment.

-

For systems that are less then 600V, considering a busbar systems can reduce panel size by 25%.

CAN WE HELP WITH THE DESIGN OF YOUR NEXT SYSTEM?

- Cost Reduction & Energy Efficiency

- Reliability & Equipment Downtime

- Safety Compliance & Traceability

- Industrial Components (Power, Control, Network, Connectivity)

- Efficiency & Precision

- Space Savings

At Dynamic, we know a thing or two about designing and building machines bound for a production environment.

- Material Selection

- Component Standardization

- Design Simplicity

- Process Efficiency

- Energy Efficiency

- Life Cycle Cost Analysis

- Supplier Negotiations

- Modular Design

- Prototyping and Testing

- Regulatory Compliance

Find out why our customers work with us from the very beginning of the design and the full range of project support we offer.

Dynamic can help you understand the potential failures and how to implement solutions to avoid or mitigate them. The initial design phase is critical to understanding the potential pitfalls and possibilities of them occurring.

- Mechanical Failures

- Electrical Failures

- Sensor and Instrumentation Failures

- Software and Control System Failures

- Human Errors

- Environmental Factors

- Supply Chain Disruptions

- Inadequate Preventive Maintenance

We can also advise you on proactive maintenance strategies, condition monitoring, timelines to perform inspections, and comprehensive preventive maintenance programs.

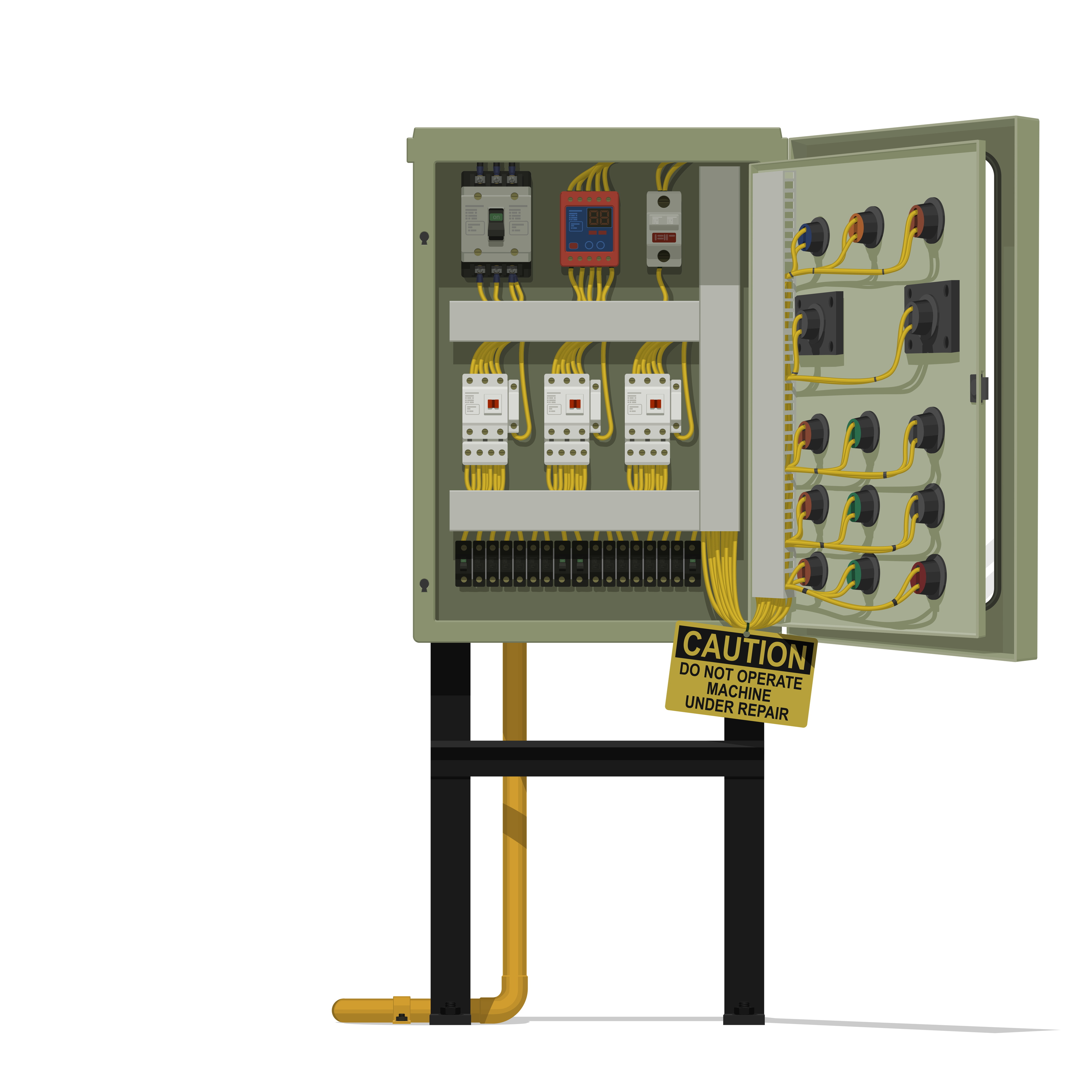

Safety systems are essential for ensuring the safety of employees and equipment in industrial equipment, such as electrical circuit protection, safety system components, emergency shutdown systems, interlock and lock-out systems. By integrating safety into your industrial control systems, you can minimize the risk of accidents and protect employees and customers from injury or harm.

- Worker Safety

- Legal Compliance

- Risk Mitigation

- Equipment Reliability

- Emergency Shutdown

- Corporate Reputation

- Product Liability

Safety compliance and traceability are integral components of industrial machine design and operation, these considerations should be prioritized throughout the entire lifecycle of industrial machines.

Industrial controls are the backbone of modern machine design, we offer rugged and reliable products bound for harsh environments. When designing your system you will want to make sure you are aware of the latest tools and technologies that enhance efficiency, safety, and overall performance. Dynamic can assist with the engineering, application, and integration of advanced control components into your machine.

- Automation and Efficiency

- Precision and Accuracy

- Safety

- Data Monitoring and Analysis

- Flexibility and Adaptability

- Cost Reduction

- Integration with Smart Technologies

- Enhanced Product Quality

- Regulatory Compliance

- Remote Monitoring and Control

- Diagnostics and Fault Detection

Our rugged and reliable products not only meet the demands of a modern manufacturing and production environment but will also allow for future expansion of your machine.

Efficiency and precision are crucial considerations in the design of industrial machinery, as they directly impact productivity, product quality, machine lifetime, and the overall effectiveness of your design. By consulting with Dynamic before design of your industrial machinery we can advise you on the critical aspects that will need careful consideration.

- Process Analysis

- Automation and Control Systems

- Sensor Technology

- Component Selection

- Tolerance Analysis

- Motion Control

- Energy Efficiency

- Maintenance Considerations

- User Interface and HMI

- Regulatory Compliance

Saving space in an industrial control panel is essential to optimize available space and maximize efficiency. Using compact components such as miniature circuit breakers, slim relays, and smaller or multi-level terminal blocks can help save space in a control panel. Dynamic can assist you with design work such as recommending compact components, planning the layout, using modular designs, utilizing vertical space, optimizing wiring, and using color-coded wiring. Our strategies will help you optimize available space, leading to improved efficiency, reduced costs, and increased productivity.

- Compact Components

- Integrated Systems

- DIN Rail Mounting

- Panel Layout Optimization

- Compact Wiring

- Remote I/O Modules

- Miniaturized Sensors and Actuators

- HMI Integration

- Modular Enclosures

- Multi-Functional Devices

- Compact Communication Protocols

- Heat Dissipation Management