Safety Compliance and Traceability

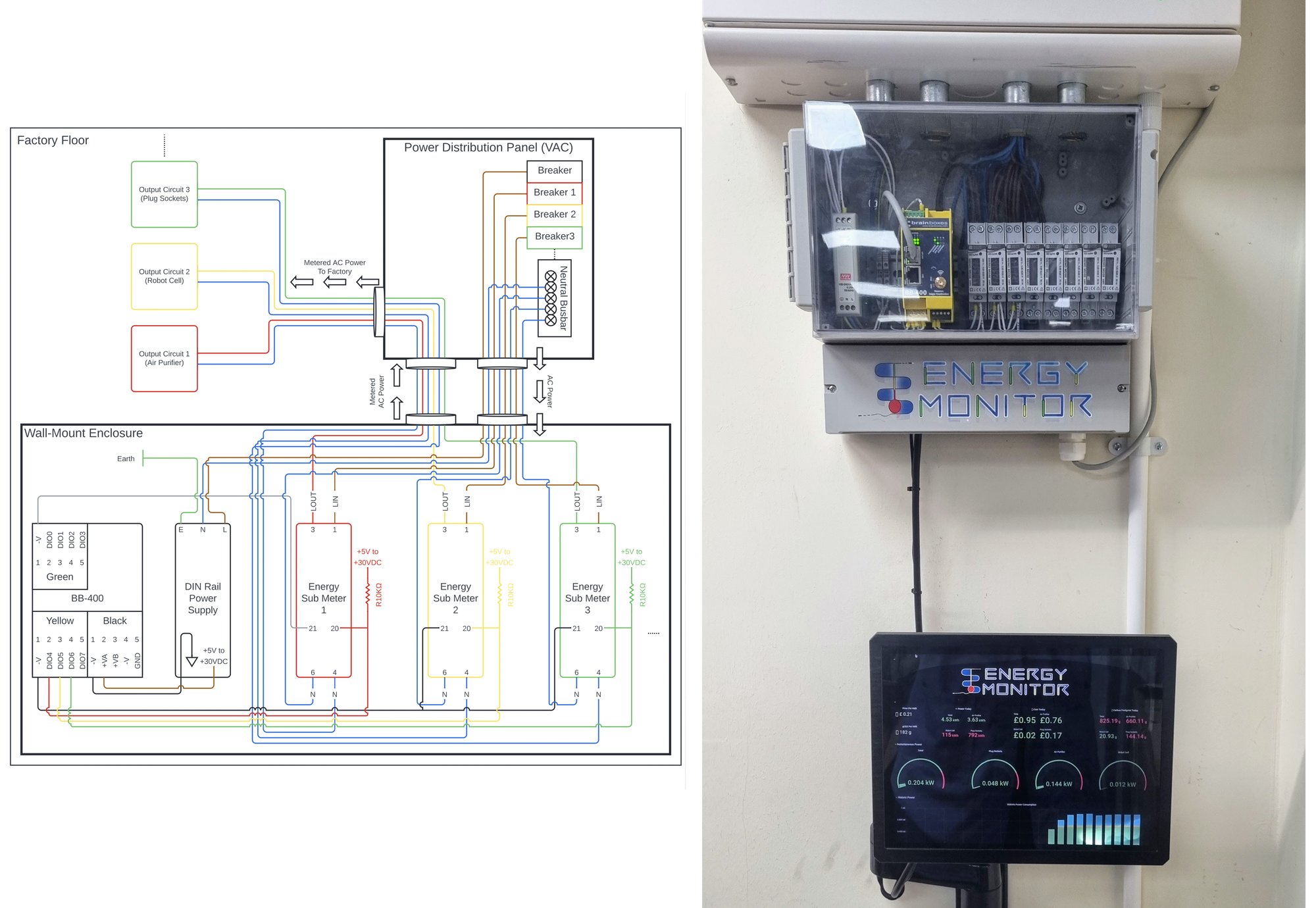

Safety Compliance and Traceability are extremely important in the design and operation of industrial equipment. Emphasizing the importance of protecting personnel, and assets, and adhering to regulations during the design process is paramount. By incorporating safety systems, such as electrical circuit protection and emergency shutdown systems, you can minimize risks and ensure equipment reliability.

SAFETY COMPLIANCE AND TRACEABILITY

Early design decisions, informed by a deep understanding of machine design and manufacturing environments, can significantly reduce costs and enhance safety. These factors underscore the importance of integrating safety considerations throughout the machine lifecycle, from conception to operation, ensuring a safer workplace and compliant machinery operation.

Worker Safety

Ensuring the safety of personnel through integrated safety systems is paramount. Incorporating features like emergency stop buttons, guards, and safety sensors can significantly reduce workplace accidents.

%20Components.jpg?width=220&height=220&name=Power%20Factor%20Correction%20(PFC)%20Components.jpg)

Legal Compliance

Adhering to national and international safety standards and regulations is non-negotiable. Compliance ensures that industrial machinery meets all legal requirements, protecting manufacturers from legal repercussions and fines.

Risk Mitigation

Identifying and addressing potential risks in the design phase minimizes the likelihood of equipment failure and accidents, enhancing overall safety and reliability.

Equipment Reliability

Reliable equipment minimizes downtime and maintenance costs. Safety features and compliance contribute to the longevity and consistent performance of machinery.

Emergency Shutdown

Systems designed for quick and safe shutdown in emergencies protect both personnel and equipment, minimizing damage and potential injuries.

Corporate Reputation

A commitment to safety enhances corporate reputation, demonstrating a dedication to employee well-being and quality manufacturing practices.

Product Liability

By prioritizing safety, manufacturers can reduce the risk of liability related to accidents or equipment malfunctions, protecting their brand and bottom line.

Inadequate Preventive Maintenance

Dynamic advocates for, and helps implement comprehensive preventive maintenance programs. We advise on proactive maintenance strategies, condition monitoring, and the optimal timelines to perform inspections to prevent equipment failures before they occur.

Regulatory Compliance

Ensuring compliance with relevant regulations, such as UL and NFPA from the design stage can avoid costly fines and redesigns. Our expertise in regulatory standards not only helps streamline the design and compliance process but ensures you have used reliable and field-proven components.