Dynamic specializes in solutions for machine builders, focusing on Power, Control, Network, and Connectivity.

TRANSPORTATION

UPDATE YOUR TRANSPORTATION CONTROL SYSTEMS WITH FIELD PROVEN ENGINEERING SOLUTIONS

|

|

Top 5 problems Transportation Designers face

1. Energy Efficiency and Power Management

- Problem: Maximising energy efficiency is critical for reducing operating costs and environmental impact, especially for EVs and electrified trains.

- Solution: Advanced power conversion systems, efficient battery management systems (BMS), regenerative braking systems, and lightweight components to improve overall energy efficiency.

2. Durability and Reliability Under Harsh Conditions

- Problem: Transportation equipment must withstand vibration, extreme temperatures, moisture, and other harsh environmental conditions without compromising performance or safety.

- Solution: Ruggedized components, vibration-resistant connectors, IP-rated enclosures, and corrosion-resistant materials designed for long-term durability in challenging environments.

3. Safety and Standards Compliance

- Problem: Ensuring passenger and operator safety while meeting stringent regulatory standards (e.g., ISO 26262 for EVs, EN 50155 for railway electronics) is complex and critical.

- Solution: Certified safety components like fail-safe relays, emergency stop systems, and advanced collision detection and monitoring sensors to ensure compliance and safety.

4. Weight Optimization

- Problem: Reducing weight is essential to enhancing fuel efficiency, extending battery life, and meeting payload requirements, but it must not compromise strength or durability.

- Solution: Lightweight materials such as composites and aluminum, compact and high-power-density components, and optimized structural designs to balance weight and performance.

5. Integration of Advanced Technologies

- Problem: Incorporating technologies like IoT, autonomous systems, and advanced driver assistance systems (ADAS) requires seamless integration of sensors, communication systems, and control algorithms.

- Solution: High-speed networking components (e.g., Ethernet switches, gateways), modular control systems, and real-time processing solutions to enable smooth integration and functionality.

Featured PRODUCTS

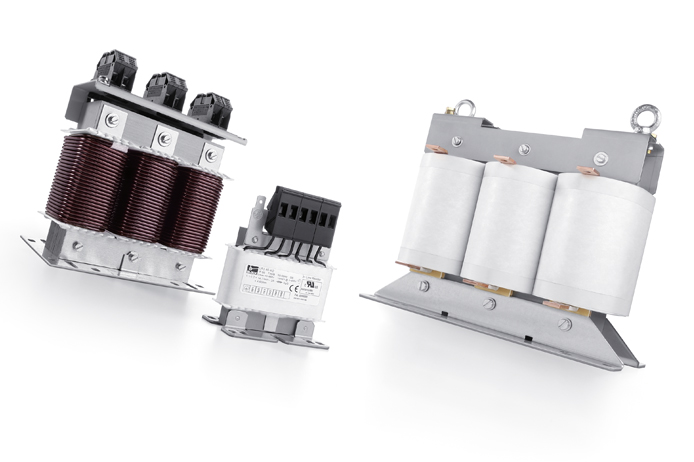

CUSTOM LINE REACTORS & TRANSFORMERS

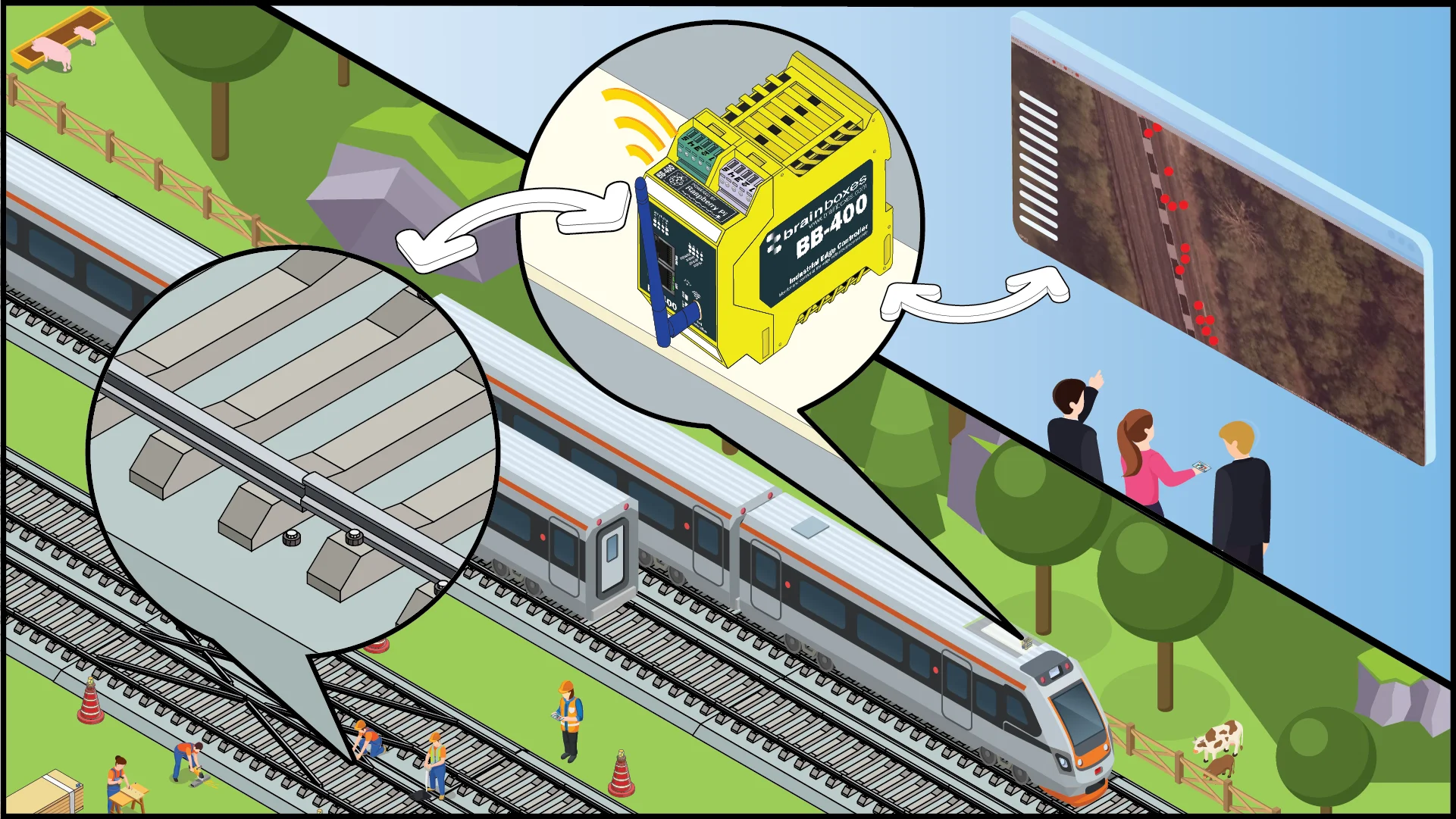

Condition monitoring

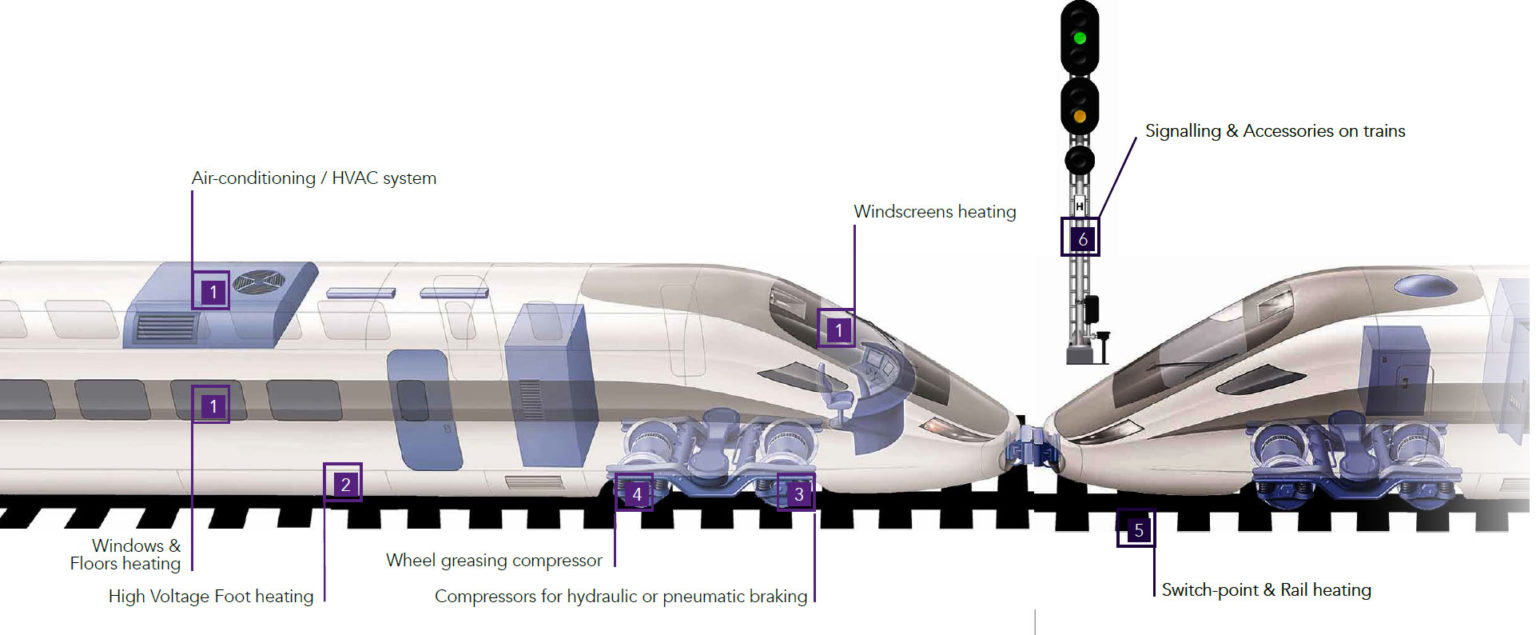

Heating/Cooling, Braking & Signaling

Cable glands/ Cable seals

Power conversion

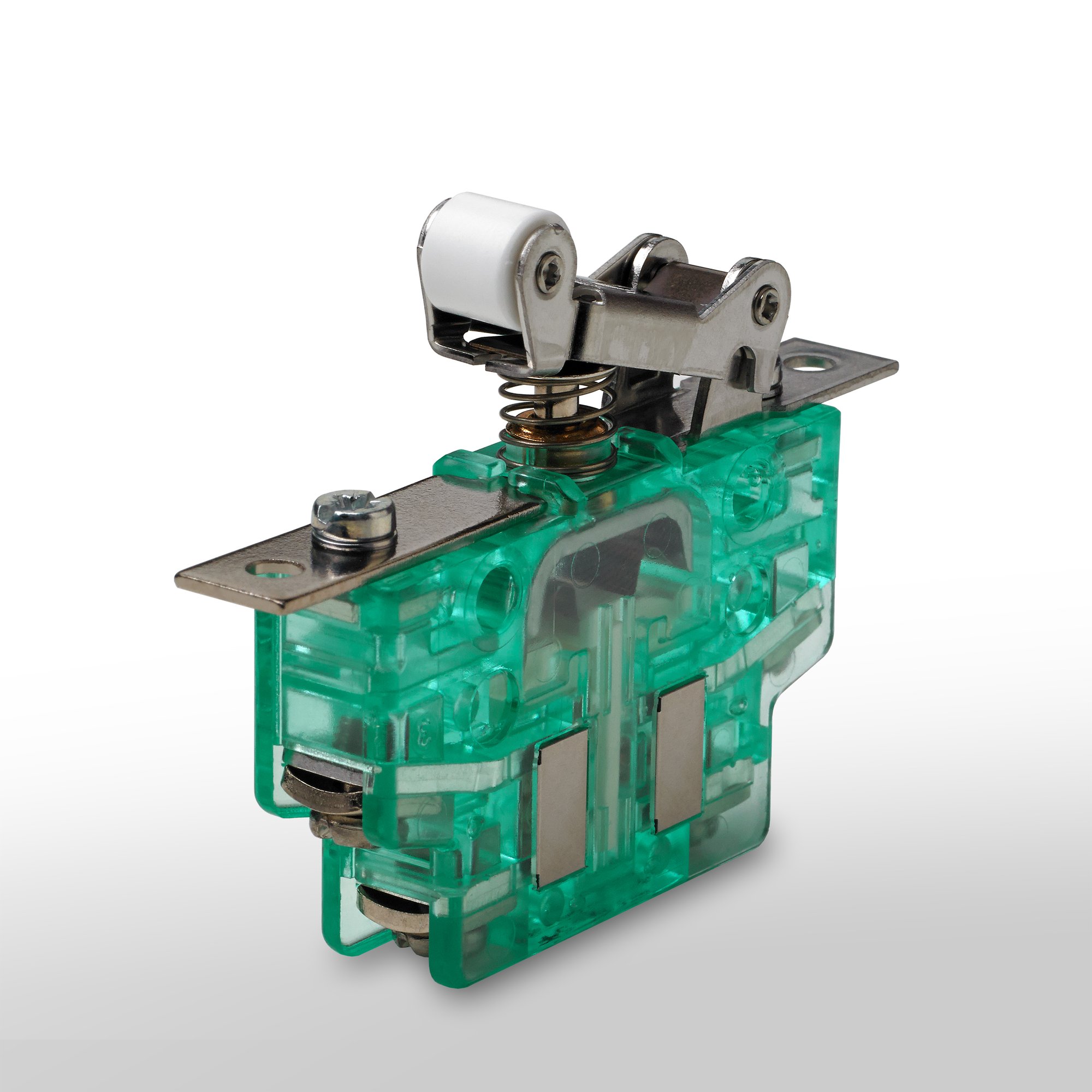

DC load breaking

heavy duty connectors

-

You can optimize industrial equipment costs by prioritizing certain factors. Making design decisions early based on a comprehensive understanding of machine design and manufacturing environments can lower costs in several areas for you and your end user.

-

Machine downtime can be attributed to various causes and failures, including electrical issues and the industrial control components. Understanding and addressing these potential failure points early on in the design are crucial for minimizing downtime and ensuring the reliability of industrial equipment.

-

This is perhaps the most critical aspect of industrial machine design is to ensure the well-being of personnel, protect assets, and maintain regulatory adherence.

-

Play a pivotal role in machine design by making it possible to control, monitor, regulate, and automate various processes.

-

By addressing these critical aspects during the design phase, industrial machinery will operate with high efficiency and precision, meeting the demands of modern manufacturing and contributing to the overall success of your industrial process equipment.

-

For systems that are less then 600V, considering a busbar systems can reduce panel size by 25%.

CAN WE HELP WITH THE DESIGN OF YOUR NEXT SYSTEM?

- Cost Reduction & Energy Efficiency

- Reliability & Equipment Downtime

- Safety Compliance & Traceability

- Industrial Controls

- Efficiency & Precision

- Space Savings

Cost Reduction & Energy Efficiency

At Dynamic, we know a thing or two about designing and building machines bound for a production environment.

- Material Selection

- Component Standardization

- Design Simplicity

- Process Efficiency

- Energy Efficiency

- Life Cycle Cost Analysis

- Supplier Negotiations

- Modular Design

- Prototyping and Testing

- Regulatory Compliance

Find out why our customers work with us from the very beginning of the design and the full range of project support we offer.

Reliability & Equipment Downtime

Dynamic can help you understand the potential failures and how to implement solutions to avoid or mitigate them. The initial design phase is critical to understanding the potential pitfalls and possibilities of them occurring.

- Mechanical Failures

- Electrical Failures

- Sensor and Instrumentation Failures

- Software and Control System Failures

- Human Errors

- Environmental Factors

- Supply Chain Disruptions

- Inadequate Preventive Maintenance

We can also advise you on proactive maintenance strategies, condition monitoring, timelines to perform inspections, and comprehensive preventive maintenance programs.

Safety Compliance & Traceability

Safety systems are essential for ensuring the safety of employees and equipment in industrial equipment, such as electrical circuit protection, safety system components, emergency shutdown systems, interlock and lock-out systems. By integrating safety into your industrial control systems, you can minimize the risk of accidents and protect employees and customers from injury or harm.

- Worker Safety

- Legal Compliance

- Risk Mitigation

- Equipment Reliability

- Emergency Shutdown

- Corporate Reputation

- Product Liability

Safety compliance and traceability are integral components of industrial machine design and operation, these considerations should be prioritized throughout the entire lifecycle of industrial machines.

Industrial Controls

Industrial controls are the backbone of modern machine design, we offer rugged and reliable products bound for harsh environments. When designing your system you will want to make sure you are aware of the latest tools and technologies that enhance efficiency, safety, and overall performance. Dynamic can assist with the engineering, application, and integration of advanced control components into your machine.

- Automation and Efficiency

- Precision and Accuracy

- Safety

- Data Monitoring and Analysis

- Flexibility and Adaptability

- Cost Reduction

- Integration with Smart Technologies

- Enhanced Product Quality

- Regulatory Compliance

- Remote Monitoring and Control

- Diagnostics and Fault Detection

Our rugged and reliable products not only meet the demands of a modern manufacturing and production environment but will also allow for future expansion of your machine.

Efficiency & Precision

Efficiency and precision are crucial considerations in the design of industrial machinery, as they directly impact productivity, product quality, machine lifetime, and the overall effectiveness of your design. By consulting with Dynamic before design of your industrial machinery we can advise you on the critical aspects that will need careful consideration.

- Process Analysis

- Automation and Control Systems

- Sensor Technology

- Component Selection

- Tolerance Analysis

- Motion Control

- Energy Efficiency

- Maintenance Considerations

- User Interface and HMI

- Regulatory Compliance

Space Savings

Saving space in an industrial control panel is essential to optimize available space and maximize efficiency. Using compact components such as miniature circuit breakers, slim relays, and smaller or multi-level terminal blocks can help save space in a control panel. Dynamic can assist you with design work such as recommending compact components, planning the layout, using modular designs, utilizing vertical space, optimizing wiring, and using color-coded wiring. Our strategies will help you optimize available space, leading to improved efficiency, reduced costs, and increased productivity.

- Compact Components

- Integrated Systems

- DIN Rail Mounting

- Panel Layout Optimization

- Compact Wiring

- Remote I/O Modules

- Miniaturized Sensors and Actuators

- HMI Integration

- Modular Enclosures

- Multi-Functional Devices

- Compact Communication Protocols

- Heat Dissipation Management