MACHINE BUILDERS

-

Industrial Automation

Industrial Automation Machines include robots, conveyors, and assembly machines used in manufacturing and production lines.

-

Material HandlingMaterial handling machines move, store, control, and protect materials, packages, and products.

Material HandlingMaterial handling machines move, store, control, and protect materials, packages, and products. -

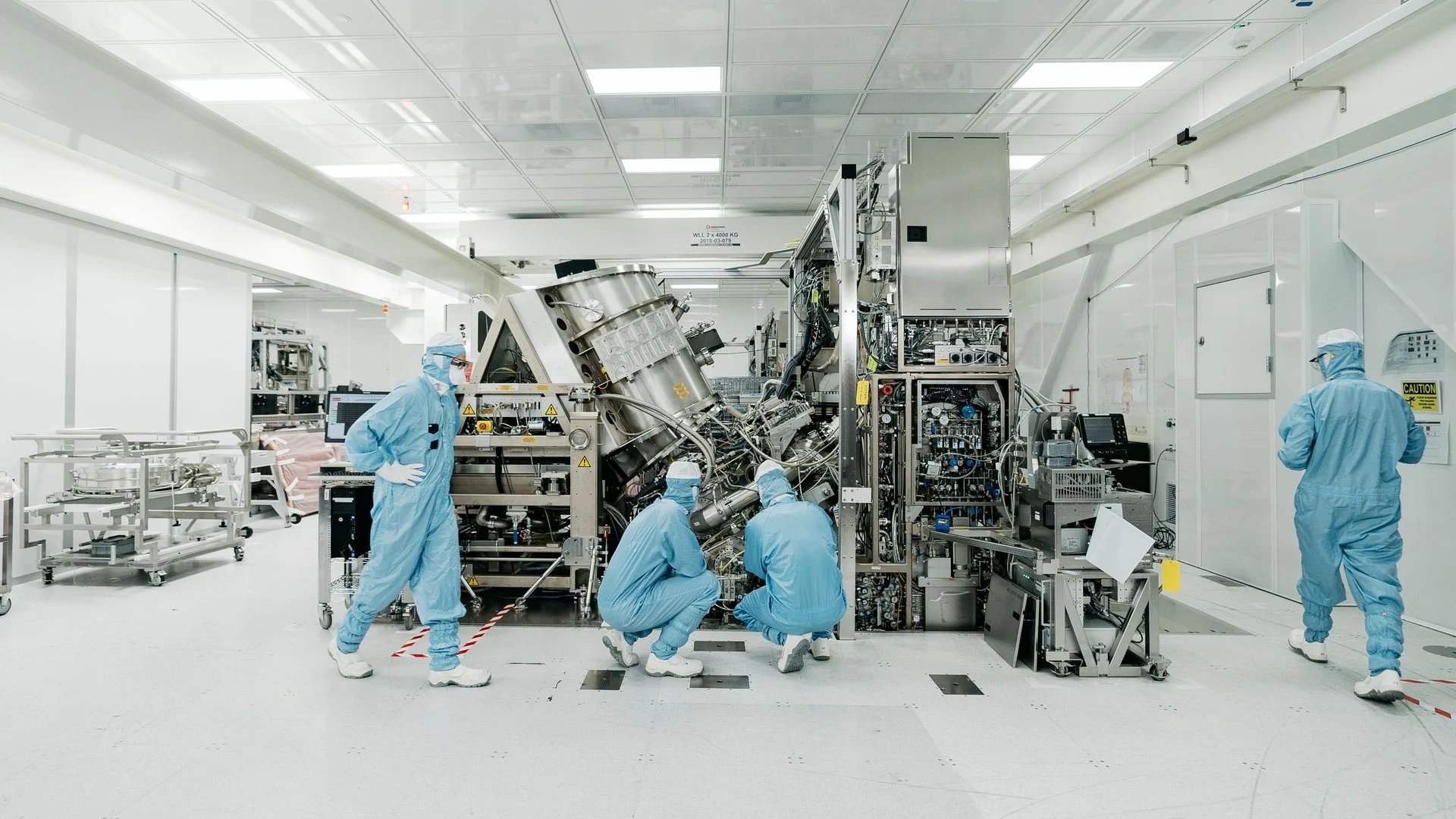

Semiconductor ToolingSemiconductor tooling is a machine used to manufacture semiconductors; it processes and manipulates silicon wafers.

Semiconductor ToolingSemiconductor tooling is a machine used to manufacture semiconductors; it processes and manipulates silicon wafers. -

Pharmaceutical and Biotech Equipment

Pharmaceutical and biotech machines are specialized equipment for producing pharmaceuticals and biotechnology products. Typical functions include mixing, filling, labeling, and packaging products.

-

Packaging and Inspection Equipment

Package handling equipment is used to transport, sort, and process cargo through the shipping and handling process.

-

Water Treatment and WastewaterMachines in the water and wastewater industry treat and process water and wastewater to ensure safe consumption or discharge into the environment.

Water Treatment and WastewaterMachines in the water and wastewater industry treat and process water and wastewater to ensure safe consumption or discharge into the environment. -

Plastic ExtrusionThe plastic extrusion machine melts raw pellets or granules and forces the molten plastic through a die to create plastic products such as tubes, sheets, or film.

Plastic ExtrusionThe plastic extrusion machine melts raw pellets or granules and forces the molten plastic through a die to create plastic products such as tubes, sheets, or film. -

Lighting and HVAC controlsLighting and HVAC control equipment optimize energy efficiency, reduce costs, and enhance occupant comfort and productivity.

Lighting and HVAC controlsLighting and HVAC control equipment optimize energy efficiency, reduce costs, and enhance occupant comfort and productivity. -

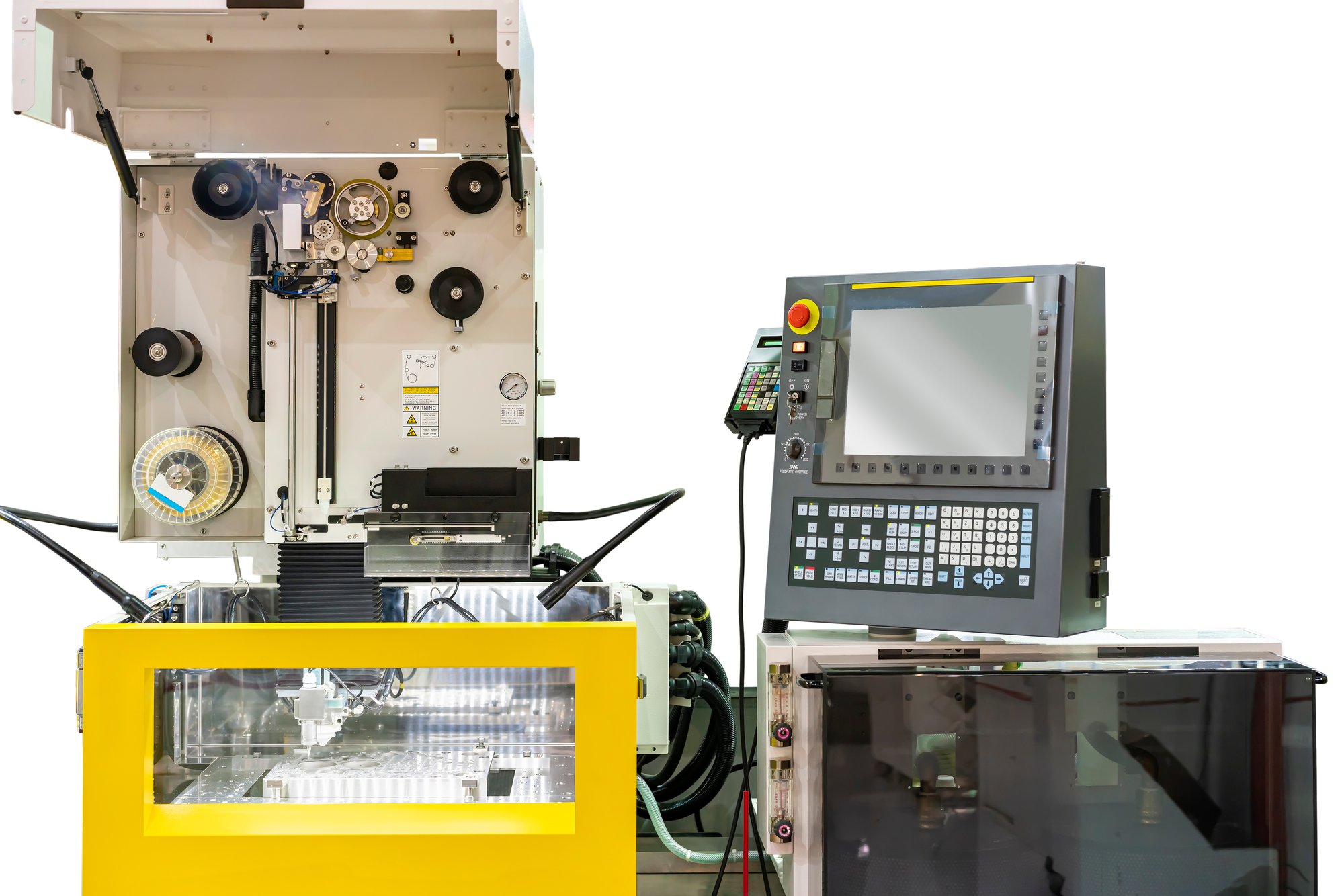

Machine Tools

Machine tools enable precision cutting, shaping, and drilling of materials. These tools incorporate industrial processes, real-time monitoring, and control through devices that connect and communicate between different systems.

Top 5 Challenges an OEM Machine Designer Faces

1. Integration Challenges Across Diverse Systems

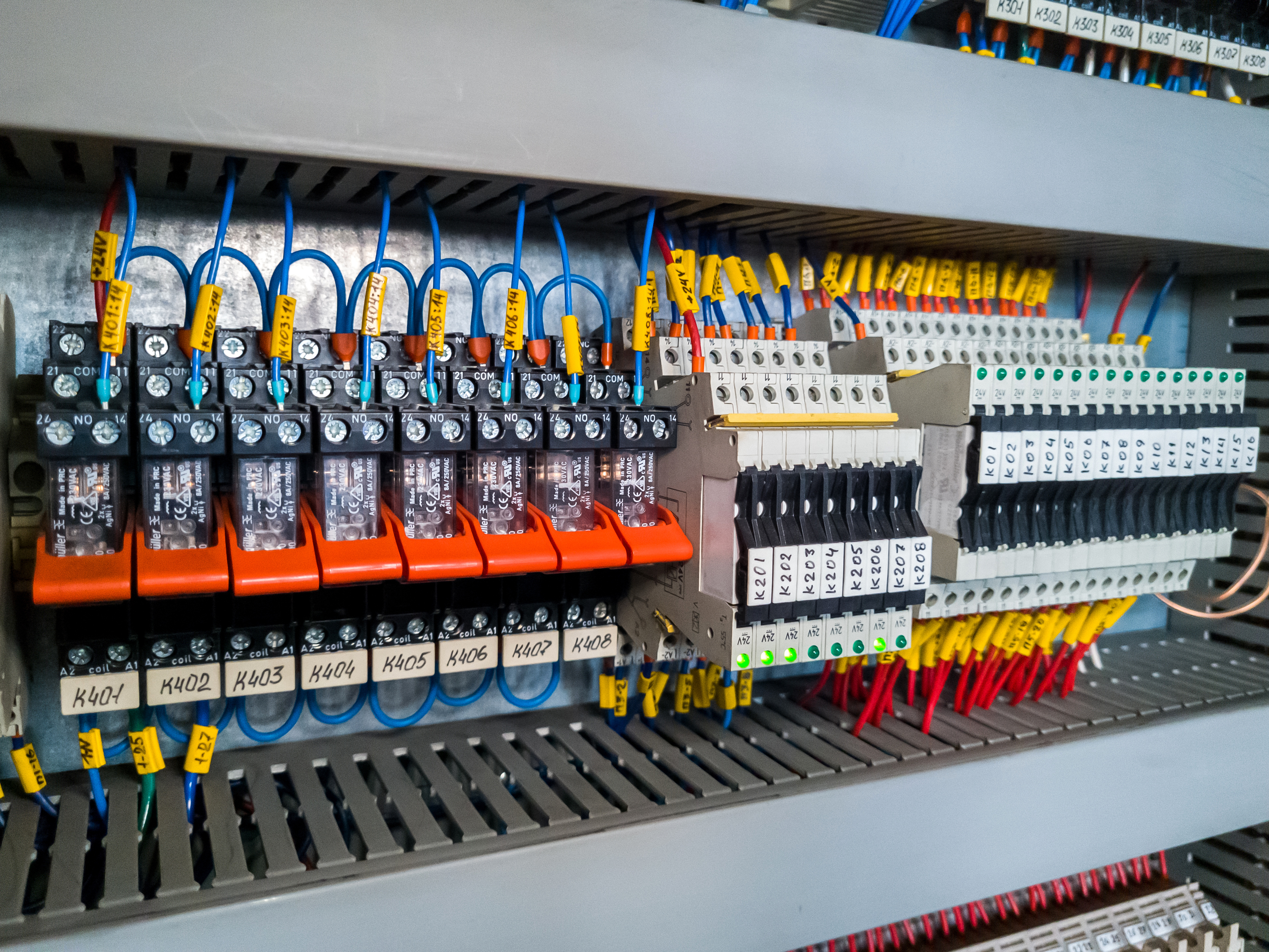

- Problem: Machines often require components from multiple vendors (PLCs, HMIs, drives, sensors) that don’t seamlessly integrate, causing delays in commissioning and troubleshooting.

- Solution: Components with open communication protocols (e.g., Ethernet/IP, Modbus, Profinet) and gateways/controllers that simplify system integration.

2. Inconsistent Component Quality

- Problem: Some components fail prematurely or don’t meet the performance specifications promised, leading to higher warranty claims and reduced customer satisfaction.

- Solution: Reliable, industrial-grade components from reputable manufacturers with robust quality testing and support services.

3. Downtime from Electrical Noise and Signal Interference

- Problem: High-frequency noise from motors, drives, and other equipment affects signal reliability, causing intermittent machine failures or communication issues.

- Solution: Shielded cabling, noise filters, and signal conditioning devices to improve reliability in noisy environments.

4. Supply Chain and Lead Time Issues

- Problem: Delays in component availability disrupt production schedules, increase costs, and affect on-time delivery to customers.

- Solution: Vendors with consistent stock availability, quick lead times, or alternative compatible components to mitigate delays.

5. Customer-Specific Customization Requirements

- Problem: Customers frequently request bespoke modifications to standard machine designs, which increases design complexity, costs, and lead times.

- Solution: Modular components, flexible control systems that allow for customization without significant redesign, and support from suppliers to quickly adapt to new requirements.

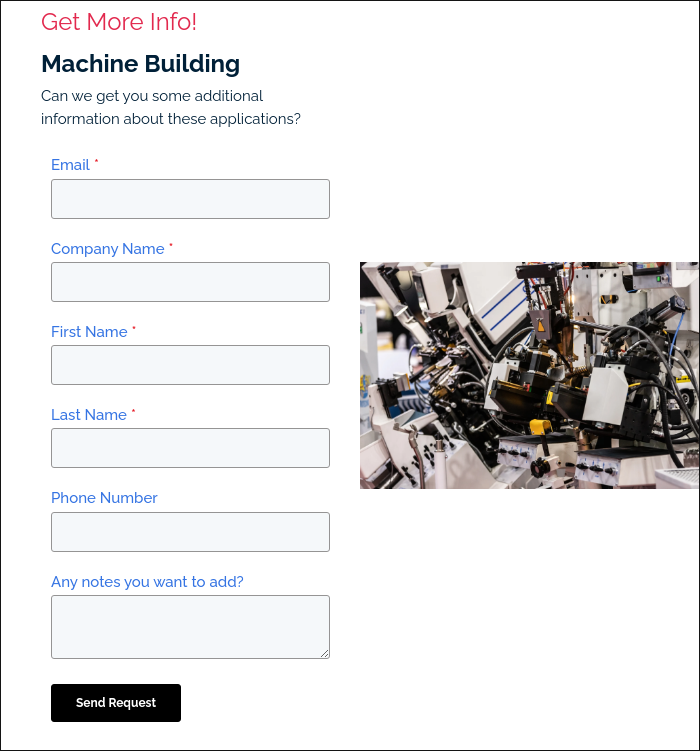

Whether you're designing OEM machines or custom equipment, certain challenges can slow you down or make processes less efficient. Translating a concept into a workable design is sometimes tricky, time-consuming, or expensive. Need a hand? Dynamic can provide anything from straightforward advice to comprehensive design assistance.

We support machine builders across various industries, staying current with the latest standards and trends. Reliability is critical for OEM machine components, especially in high-speed, extreme-condition applications where uptime is non-negotiable. Achieving harmony between electrical and mechanical systems demands careful planning and expertise. Cutting corners or using poorly implemented components can lead to costly failures.

Dynamic offers in-depth knowledge of electrical controls, electronics, and system design. We've also created helpful guides covering industrial control panel types, electrical control products, and essential industry standards for machine building. Let us help with your machine designs and keep your customers happy by keeping them up and running longer and more efficiently.

Dynamic specializes in products and Engineered solutions that solve Power, Control, Network, and Connectivity Challenges.

If you have questions about machine design, electrical control panels, or industrial components, or just need to know the important considerations before you start designing, please reach out.

Recent Post