Your machine can only perform as well as the connections behind it. Signal loss, intermittent faults, or failed terminations don’t just hurt performance — they cost time, create safety risks, and undermine trust in your system.

Connection failure isn't an option, especially if your machine is destined for production. That’s why we guide you in designing systems with long-lasting, high-integrity wiring solutions—from terminal blocks and connectors to cable routing, strain relief, and wire termination.

Connections Aren’t Just a Detail, They’re the Foundation

Clean wiring, dependable terminations, and well-managed cables don’t just make your panel look good — they reduce install time, cut down on troubleshooting, and keep machines running longer with fewer surprises.

What’s at Risk?

🟥 Loose wires cause intermittent failures

🟥 Poor cable layout leads to overheating

🟥 Harsh environments demand rugged protection

🟥 Mistakes during assembly cost hours in rework

We’ve walked the floors, traced wire bundles through enclosures, and solved connection failures that only show up after a thousand cycles. Dynamic brings real-world application knowledge that helps your wiring last longer and perform better.

Clean Wiring Builds Better Machines

Every electrical path is a potential point of failure — or a moment to get it right. Whether you’re building a control panel, wiring a robotic cell, or managing complex I/O, we help you think through the details that keep it running.

- Correctly rated connectors for voltage, current, and environment

- Shielded cabling with proper grounding to prevent EMI

- Panel-ready kits and pre-terminated harnesses that cut build time

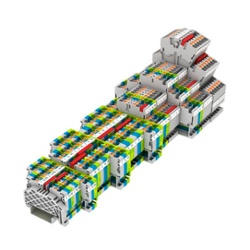

- DIN-rail terminal blocks and ferrules for faster, safer wiring

- Wire ducts, cable trays, and routing aids to reduce clutter and improve airflow

- Strain reliefs, bulkhead feedthroughs, and seals that stay put under stress

Build Faster. Wire Smarter. Scale Easier.

-

"Prevent downtime and failures with expert component selection."

-

"Simplify your build. Save hours on install and service."

-

"Get to production faster with trusted components and application insight."

-

"Spend less on maintenance. Protect your investment from Day 1."

-

"Plan ahead. Build systems ready for upgrades and expansions."

-

"We help you meet codes, pass inspections, and avoid compliance risks."

CAN WE HELP WITH THE DESIGN OF YOUR NEXT SYSTEM?

- Stable, Reliable Systems

- Cleaner, More Organized Builds

- Faster Time to Production

- Lower Total Cost of Ownership

- Scalable, Future-Ready Designs

- Risk Reduction & Compliance

A well-designed electrical system is the foundation of machine reliability.

Clean panel layouts, proven component choices, and smart power distribution aren’t just nice to have — they prevent hidden failures, downtime, and costly service calls.

Dynamic works with machine builders to engineer stability into every design, selecting components and layouts that deliver consistent, error-free operation at production scale.

-

Thermal Management Through Component Placement

-

Power Quality Optimization via Harmonic Analysis

-

Scalable Architecture for Future Expansion

-

Advanced Grounding and Bonding Techniques

Smart wiring and layout design are critical to scaling production efficiently.

Organized panels, labeled connectors, and clean cable routing don’t just look better — they simplify installation, speed up troubleshooting, and reduce service labor across every machine you build. Dynamic helps machine builders design electrical systems that are easier to build, inspect, and maintain — saving time today and service costs tomorrow.

- Optimized Wire Routing for Electromagnetic Compatibility (EMC)

- Standardized Labeling for Efficient Troubleshooting

- Modular Panel Design for Scalability

- Integrated Cable Management Systems

Trusted components and smart system design speed up every stage of production.

Every delay in build or debug is money lost. A reliable system means fewer last-minute surprises so that you can ship on schedule (or ahead of schedule).

- Protect Your Design Integrity

- Shorten the Debugging Loop

- Deliver a Better First Impression

- Gain Time for Innovation

Every decision you make at the design stage impacts long-term system cost.

Stable power distribution, serviceable layouts, and proven components protect your machines from costly downtime, maintenance events, and early failures. Dynamic helps you engineer smarter systems that deliver value long after the first machine ships — protecting your investment from day one.

- Design for the Full Lifecycle

- Minimize Future Service Costs

- Protect Your Machine’s Reputation

- Turn Design Discipline Into Profit

Your machine designs need to perform today — and adapt for tomorrow.

Dynamic helps OEMs build modular, future-ready electrical systems that scale easily, support upgrades, and minimize redesign costs when requirements change.

We work with machine builders to design flexibility into every system, giving your equipment a longer and more profitable life cycle.

-

Design Once, Scale Many

-

Simplify Upgrades and Retrofits

-

Protect Against Shifting Requirements

-

Extend Your Machine’s Profit Window

Meeting today's safety and regulatory standards is only getting harder — and more critical.

Dynamic helps machine builders integrate compliance into their designs from the ground up, simplifying UL, CE, NEC, and global inspection processes while minimizing field risk.

Protect your customers, brand reputation, and ability to scale globally, starting at the electrical design level.

- Engineer Compliance Into the Blueprint

- Simplify Global Scalability

- Reduce Field Liability Exposure

- Turn Compliance Into a Competitive Edge

Let’s Build It Right the First Time

Designing reliable connections means fewer service calls, better performance, and machines your customer actually enjoys maintaining. We’ll help you make smart choices now — before wiring becomes a weak link.

How We Help You Design for Long-Term Connection Integrity

Whether designing a machine or building the panel that powers it, our "Wired to Last" solutions help you engineer long-term connection integrity with the right terminal blocks, cable routing, rugged connectors, and protection strategies — so your builds stay solid, cycle after cycle.

Terminal Blocks That Lock In Confidence

Push-in, screw clamp, or DIN-mount—we help you pick the right termination method for your current rating, wire type, and vibration environment.

Click here for details ▼

Industrial-Grade Connectors That Stay Put

From IP-rated circular connectors to power/data hybrids, we specify connectors that simplify maintenance and ensure a tight seal, even in wet or dusty conditions.

Click here for details ▼

Cable Management for Efficient Routing

Reduce EMI, increase serviceability, and speed up production with cable trays, harnessing strategies, and organized panel layouts that actually scale.

Click here for details ▼

Protection That Matches the Application

We help you spec the right conduit, sealing glands, and over-molded strain reliefs so your system survives flexing, chemicals, or heat cycles without failure.

Click here for details ▼

Let’s Build the Connections That Hold It All Together

Because chasing loose wires and tracking intermittent faults isn’t why you became an engineer, let’s get it wired right, the first time.