Process Control Systems

Process control systems refer to the monitoring, controlling, and regulating of industrial processes using a variety of technologies and approaches.

The objective of process control systems is to ensure that the process runs within the specified parameters, yields a consistent and high-quality result, and performs as efficiently as feasible.

Control panels are an integral part of process control systems, acting as the interface between the operator and the process. Control panels may have a variety of instruments, displays, and controls that enable the operator to monitor process parameters, alter settings, and make necessary adjustments. Control panels can be automated and connected with other control systems, such as computerized control systems, to offer monitoring and control of the process in real time.

Overall, process control systems serve a crucial role in ensuring the quality, efficiency, and safety of industrial processes and are utilized in a variety of industries, such as the petrochemical, food and beverage, pharmaceutical, and others.

Made from lightweight yet durable materials like fiberglass, polycarbonate, and PVC, these enclosures offer excellent protection against harsh industrial environments, including dust, moisture, chemicals, and extreme temperatures. The Ensto Polybox has a very stylish and modern appearance as well as maintains a rugged look and feel, not like some other brands that feel "cheap and flimsy".

Available in standard JIC (Joint Industrial Council) sizes from 8x6x4 through 18x16x10

- Corrosion Resistant

- Light Weight

- Temperature Stable

- Cannot Become Electrically Conductive

- No Sharp Corners

- Easy to Modify (no special tools)

- Rugged and Long Life Span

- Overall Very Cost Effective

An HMI (Human Machine Interface) is an essential component of an industrial control panel that provides a graphical user interface for interacting with the underlying control systems. The primary purpose of an HMI is to display real-time process data and provide a means for operators to interact with the control system.

- Easy to Use

- Real-time Information

- Alarms and Notifications

- Data Logging and Reporting

- Communication with the Control Systems

- Customizable

- Secure

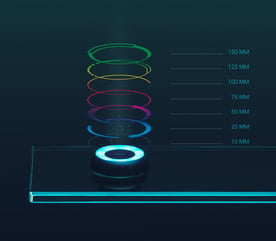

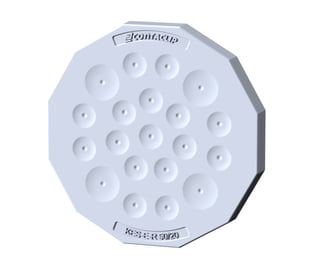

Cable entry frames are used in industrial control panels to provide a secure and organized means for cables to enter and exit. They help protect cables from damage and ensure wires are organized; they can also prevent unauthorized access to the control panel, where a cable gland just be unscrewed.

A tool-free, IP66, or IP54 sealed passage or insertion of assembled and unassembled cables and hoses are made possible by CONTA-CLIP's cable entry systems.

- Cable Protection

- Cable Organization

- Environmental Protection

- Easy to Install

- Cost Effective

The most popular application in industrial control panels will be to step-down 480VAC to 120VAC.

Primarily engineered for isolation, lighting, or signal systems, the CT series provides an economical and efficient solution under regular and even abnormal conditions. They ensure a robust design and a continuous electrical supply of your control circuits.

Our TT3 is available for 3-phase and high-power applications up to 600V and ratings from 10kVA to 1MVA.

NEW - Push-In Terminal Block Transformer Connection

Save time on wiring, safe in high vibration applications, no re-torquing required.

A switching power supply uses sophisticated electronics to convert AC or DC to a commonly used DC voltage. The most popular application in a din rail mount power supply is to convert 120VAC to 24VDC, although other combinations such as 48V, 12V, and 5V DC are also possible.

Our new PCC series of 24VDC power supplies

Have a robust construction (metal housing) and meet all international safety standards. making the perfect for harsh industrial environments. Additionally, their high-quality components, including the new push-in terminals, ensure stable and consistent voltage output, ensuring long-term performance and minimal downtime. High-quality AC/DC 24V din rail mount power supplies are crucial for industrial control panels' efficient and safe operation.

- Detecting position and presence

- Security of a machine

- Speed Detection

- Level measurement

Magnetic sensors are used to monitor or control a level, a passage, a movement, a position, a speed

- AC and DC switching

- No power supply required

- Can operate in harsh environments

- Extensive sensing range

- Cost-effective solution

- Long service life

Controllers, Ethernet Gateways, and Industrial Network Switches

Industrial Edge Controller, powered by an industrialized Raspberry Pi and Arduino

Multiple connections, built-in UPS for power management

Comes with easy-to-use secure web interface

Process data locally and send it to the cloud. Use our built-in software or write your own with open-source tools

Develop on Pi and deploy seamlessly to Industry

-25°C to +80°C op temp range, 5-30VDC dual power input with built-in mini UPS, DIN rail mountable

Ethernet Gateways and I/O (Digital, Analog, Temperature)

Send Serial and other types of data over the internet ...

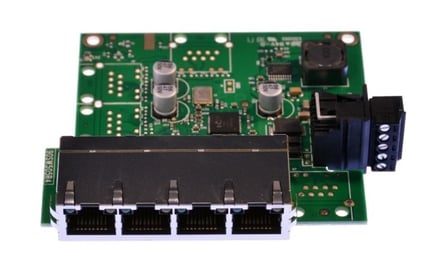

Network Switches

Industrial Ethernet switches are crucial in modern industrial networking systems, providing secure, reliable, and high-speed communication between different devices. These network switches are designed to operate in harsh industrial environments, with features such as extended temperature range, rugged enclosures, and enhanced reliability.

- 4, 5, or 8 ports

- Industrial temperature range -40°C to +80°C / -40°F to +176°F

- Redundant dual power inputs: +5V to +30V DC

- Integrated DIN Rail Mount with ground connection

- Power status LED

- Status and Link LEDs for each RJ45 Magnetic Jack Ethernet Socket

- Power consumption is optimized based on the status of the link device

Using industrial Ethernet switches in factories, power plants, and other industrial settings can help improve operational efficiency, increase process control and automation, and reduce downtime. They also support various protocols, including TCP/IP, Modbus, and Profinet, making them highly compatible with multiple industrial devices. Additionally, many industrial Ethernet switches come equipped with advanced security features, such as firewalls, VLANs, and VPNs, to help protect against cyber threats. The use of industrial Ethernet switches is a critical factor in the growth and development of Industry 4.0 and the Internet of Things (IoT) in industrial environments.

We develop custom HMI Systems!

An HMI (Human Machine Interface) is an essential component of an industrial control panel that provides a graphical user interface for interacting with the underlying control systems. The primary purpose of an HMI is to display real-time process data and provide a means for operators to interact with the control system.

- Easy to Use

- Real-time Information

- Alarms and Notifications

- Data Logging and Reporting

- Communication with the Control Systems

- Customizable

- Secure

Some examples of our work:

We also supply Ruggedized Keyboards:

And Capacitive and Optical Pushbuttons!

Get in touch to discuss an upcoming application and get a quote!

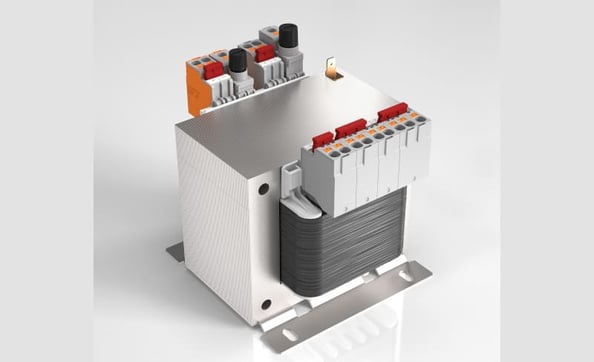

BLOCK’s line of CT series control power transformers is the perfect choice for general-purpose and industrial applications, up to 2500VA.

The most popular application in industrial control panels will be to step-down 480VAC to 120VAC.

Primarily engineered for isolation, lighting, or signal systems, the CT series provides an economical and efficient solution under regular and even abnormal conditions. They ensure a robust design and a continuous electrical supply of your control circuits.

Our TT3 is available for 3-phase and high-power applications up to 600V and ratings from 10kVA to 1MVA.

NEW - Push-In Terminal Block Transformer Connection

Save time on wiring, safe in high vibration applications, no re-torquing required.

No tools, no screws, simply plug in and go, and release with just one click.

Standard Industrial Control Transformers

- Efficient

- Compact

- Voltage Control

- Safety & Isolation

When choosing an industrial control transformer for a control panel, several crucial factors should be considered. The following are some of the most vital considerations:

Voltage and current ratings: When choosing a transformer, ensure it has the proper voltage and current ratings for the intended use. Verify that the transformer can manage the voltage and current needed to power the load.

Frequency: The transformer's frequency should coincide with the electrical supply's frequency.

Insulation class: The transformer needs to have an insulation class appropriate for the control panel's voltage levels and operating conditions.

Efficiency: A more energy-efficient transformer will generate less heat, lowering the possibility of thermal damage and improving reliability.

Size and weight: The transformer's size and weight should suit the control panel's available space and the design's specifications. i.e = autotransformers are small in size but do not provide isolation.

Noise production: Certain transformers may produce electrical noise, which may impair the performance of other electrical parts in the control panel.

Environment: The transformer should be able to function within the control panel's environmental parameters, such as temperature, humidity, shock, and vibration.

Safety: Verify that the transformer complies with all applicable safety regulations and standards for the intended use.

We have the proper transformer for your application; please get in touch.

A switching power supply uses sophisticated electronics to convert AC or DC to a commonly used DC voltage. The most popular application in a din rail mount power supply is to convert 120VAC to 24VDC, although other combinations such as 48V, 12V, and 5V DC are also possible.

Our new PCC series of 24VDC power supplies

Have a robust construction (metal housing) and meet all international safety standards. making the perfect for harsh industrial environments. Additionally, their high-quality components, including the new push-in terminals, ensure stable and consistent voltage output, ensuring long-term performance and minimal downtime. High-quality AC/DC 24V din rail mount power supplies are crucial for industrial control panels' efficient and safe operation.

- Universal AC Input, 85 - 264 VAC

- Universal DC Input, 90 - 374 VDC

- Operating temperature range from -25°C to +70°C, with a safe start-up of the devices guaranteed from -40°C.

- High Altitude is not a problem, guaranteed for 16,000 ft.

- Protection against transient mains overvoltage events

- Voltage withstand up to 4 kV and overvoltage category III

- High efficiency and compact design

- Protection against shock and vibration

- Wide range of safety standards and approvals

- Complies with the latest EMC standards

Let us show you why we should be the power provider for your next industrial control panel build!

Cable entry frames are used in industrial control panels to provide a secure and organized means for cables to enter and exit. They help protect cables from damage and ensure wires are organized; they can also prevent unauthorized access to the control panel, where a cable gland just be unscrewed.

A tool-free, IP66, or IP54 sealed passage or insertion of assembled and unassembled cables and hoses are made possible by CONTA-CLIP's cable entry systems.

- Cable Protection

- Cable Organization

- Environmental Protection

- Easy to Install

- Cost Effective

.jpg?width=566&height=385&name=KDS-SR_2__780X530%20(1).jpg)

Our KDS solutions for cable entry make it possible to quickly size passage seals for pre-constructed cables. They seal to tightness under IP66 protection class. You can easily change the seal in any cable frame according to the diameter of the hose or cable without disassembling the frame.

• Up to 32 wires in one frame • KDS-FB for flat cables.jpg?width=380&height=259&name=KDS-R_780X530%20(1).jpg)

.jpg?width=381&height=259&name=KDS-FB_780X530_01%20(1).jpg)

• KDSI-SR frames can be assembled outside the panel • KDS-FP frames are expandable

.jpg?width=380&height=258&name=KDS-FP_2_780X530%20(1).jpg)

• KES is a rubber, toolless seal, sealed up to IP66

.jpg?width=380&height=258&name=KES_780X530%20(1).jpg)

Dynamic specializes in Electrical Power Components, Industrial Process Control & Electro-mechanical Devices.

Electrical Power Controls

Electrical power controls are devices or components used to regulate, control, and protect the flow of electrical power to various electrical and mechanical systems. These elements include transformers, circuit breakers, contactors, relays, fuses, and motor controls. Their primary purpose is to safeguard electrical systems and equipment from overloading, short-circuiting, and other power-related hazards.

Industrial Process Control

Process control is managing and regulating an industrial process's physical and chemical variables. It uses various control devices, such as sensors, transmitters, controllers, and actuators, to measure and manipulate the process variables. The process control system typically includes monitoring, control, safety, data acquisition, communication, and ensuring that the manufacturing or production process runs efficiently and effectively.

Electro-Mechanical Solutions

Electro-mechanical solutions use a mechanical action to control an electrical function. Electro-mechanical components are essential for an industrial control panel, performing various functions such as switching, sensing, and controlling. They are also used to protect equipment and personnel from electrical hazards and to modify and send electrical signals to other devices in the circuit. Electro-mechanical solutions provide a dependable, efficient, and adaptable method of controlling processes. These are often simple devices without the complexity of internal electronics.

Don't see what you need?

Please contact us!

We have many great partners and would be happy to make a recommendation to a reliable source if we don't have what you need.

.jpg?width=1200&length=1200&name=KDS-FP_2_780X530%20(1).jpg)