Control

INDUSTRIAL COMPONENTS

To meet the application's complex demands, you Must have a comprehensive understanding of the System's needs and a thorough understanding of "how things work." This ensures that your Design will operate efficiently, safely, and reliably.

"CONTROL" STARTS WHEN YOU BEGIN ADDRESSING THE KEY FACTORS AND NEEDS DURING THE DESIGN AND IMPLEMENTATION PHASES

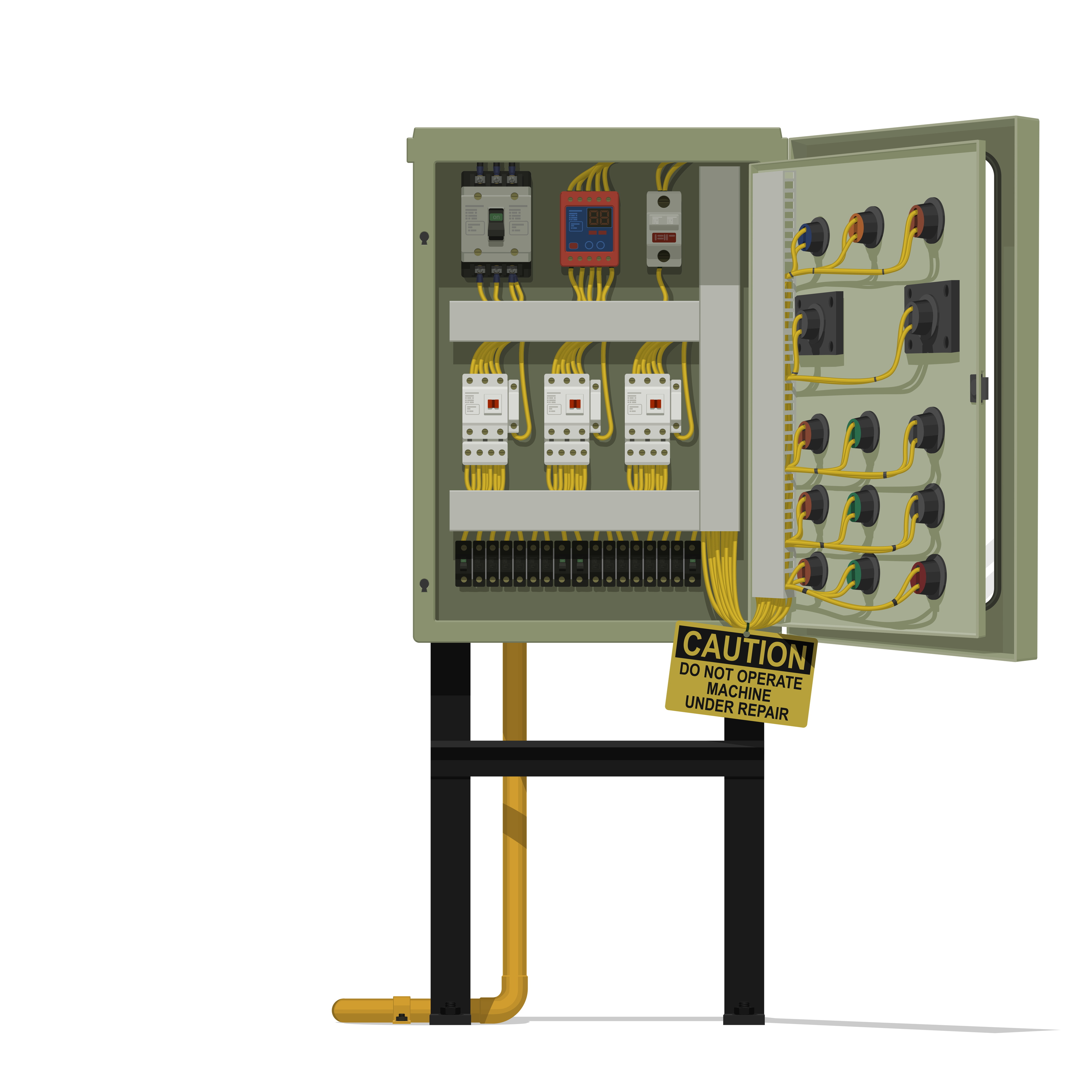

Industrial control encompasses the systems and processes used to manage and regulate the operation of industrial machines and equipment. Dynamic believes some of the most important aspects of industrial control in a machine are ...

- Control System Design and Architecture

The foundation of effective industrial control is the design and architecture of the control system itself. This includes selecting the appropriate type of control system (e.g., open-loop vs. closed-loop, PID control), determining the architecture (centralized vs. decentralized, modular vs. integrated), and ensuring the system is scalable and adaptable to future needs. A well-designed control system architecture ensures seamless operation, ease of integration with other systems, and flexibility for upgrades and expansions. - Sensors and Actuators

Sensors and actuators are the eyes and hands of an industrial control system, providing the necessary input and output capabilities. Sensors collect data from the machine and its environment, such as temperature, pressure, position, and speed, which are crucial for monitoring and control. Actuators, on the other hand, execute control actions based on commands from the control system, such as moving a valve, starting a motor, or adjusting a switch. Selecting the right sensors and actuators for the specific requirements of the machine is critical for effective control and operation. - Feedback and Real-time Control

Feedback mechanisms are essential for closed-loop control systems, allowing the system to adjust its actions based on real-time data. This enables the machine to respond dynamically to changes in the operating environment or in the process itself, maintaining optimal performance and preventing deviations from set points. Real-time control and feedback ensure high precision, efficiency, and adaptability of the machine's operation. - Human Machine Interface (HMI)

The Human-Machine Interface (HMI) provides a crucial link between the operator and the machine, allowing for monitoring, control, and intervention when necessary. An effective HMI should be intuitive, providing clear and concise information about the machine's status, alarms, and operational parameters. It should also allow for easy input of control commands and adjustments by the operator. The design of the HMI significantly affects the usability and efficiency of the machine. - Safety and Emergency Control

Safety is paramount in industrial control systems. Design engineers must incorporate safety features and emergency control mechanisms to protect both the machine and the operators. This includes fail-safe designs, emergency stop buttons, safety interlocks, and redundancy in critical components. Safety-related control systems must comply with relevant standards and regulations to ensure they provide effective protection against accidents and hazards. - Integration with Industrial Communication Networks

Integration with industrial communication networks is vital for the seamless operation of modern machinery. These networks enable the control system to exchange data with other systems and components, facilitating coordinated control, data logging, and remote monitoring. The ability to integrate with these networks enhances the flexibility and intelligence of the control system, allowing for more sophisticated control strategies and operational insights. - Cybersecurity

With the increasing connectivity of industrial systems, cybersecurity has become an essential aspect of industrial control. Design engineers must ensure that control systems are protected against cyber threats, which could disrupt operations, cause damage, or compromise safety. This includes implementing secure communication protocols, access controls, and regular security updates to safeguard the system.

-

You can optimize industrial equipment costs by prioritizing certain factors. Making design decisions early based on a comprehensive understanding of machine design and manufacturing environments can lower costs in several areas for you and your end user.

-

Machine downtime can be attributed to various causes and failures, including electrical issues and the industrial control components. Understanding and addressing these potential failure points early on in the design are crucial for minimizing downtime and ensuring the reliability of industrial equipment.

-

This is perhaps the most critical aspect of industrial machine design is to ensure the well-being of personnel, protect assets, and maintain regulatory adherence.

-

Play a pivotal role in machine design by making it possible to control, monitor, regulate, and automate various processes.

-

By addressing these critical aspects during the design phase, industrial machinery will operate with high efficiency and precision, meeting the demands of modern manufacturing and contributing to the overall success of your industrial process equipment.

-

For systems that are less then 600V, considering a busbar systems can reduce panel size by 25%.

CAN WE HELP WITH THE DESIGN OF YOUR NEXT SYSTEM?

- Cost Reduction & Energy Efficiency

- Reliability & Equipment Downtime

- Safety Compliance & Traceability

- Industrial Components (Power, Control, Network, Connectivity)

- Efficiency & Precision

- Space Savings

At Dynamic, we know a thing or two about designing and building machines bound for a production environment.

- Material Selection

- Component Standardization

- Design Simplicity

- Process Efficiency

- Energy Efficiency

- Life Cycle Cost Analysis

- Supplier Negotiations

- Modular Design

- Prototyping and Testing

- Regulatory Compliance

Find out why our customers work with us from the very beginning of the design and the full range of project support we offer.

Dynamic can help you understand the potential failures and how to implement solutions to avoid or mitigate them. The initial design phase is critical to understanding the potential pitfalls and possibilities of them occurring.

- Mechanical Failures

- Electrical Failures

- Sensor and Instrumentation Failures

- Software and Control System Failures

- Human Errors

- Environmental Factors

- Supply Chain Disruptions

- Inadequate Preventive Maintenance

We can also advise you on proactive maintenance strategies, condition monitoring, timelines to perform inspections, and comprehensive preventive maintenance programs.

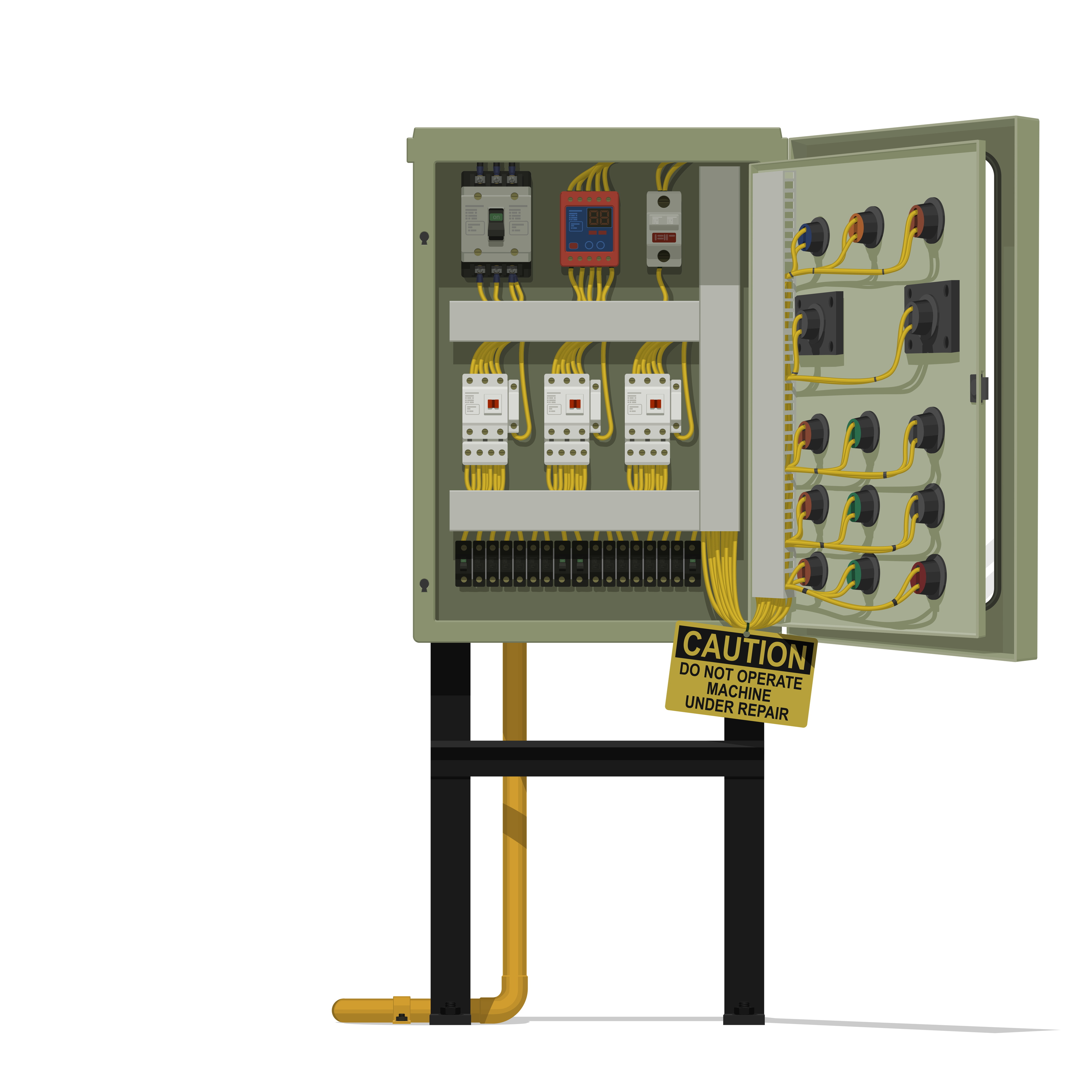

Safety systems are essential for ensuring the safety of employees and equipment in industrial equipment, such as electrical circuit protection, safety system components, emergency shutdown systems, interlock and lock-out systems. By integrating safety into your industrial control systems, you can minimize the risk of accidents and protect employees and customers from injury or harm.

- Worker Safety

- Legal Compliance

- Risk Mitigation

- Equipment Reliability

- Emergency Shutdown

- Corporate Reputation

- Product Liability

Safety compliance and traceability are integral components of industrial machine design and operation, these considerations should be prioritized throughout the entire lifecycle of industrial machines.

Industrial controls are the backbone of modern machine design, we offer rugged and reliable products bound for harsh environments. When designing your system you will want to make sure you are aware of the latest tools and technologies that enhance efficiency, safety, and overall performance. Dynamic can assist with the engineering, application, and integration of advanced control components into your machine.

- Automation and Efficiency

- Precision and Accuracy

- Safety

- Data Monitoring and Analysis

- Flexibility and Adaptability

- Cost Reduction

- Integration with Smart Technologies

- Enhanced Product Quality

- Regulatory Compliance

- Remote Monitoring and Control

- Diagnostics and Fault Detection

Our rugged and reliable products not only meet the demands of a modern manufacturing and production environment but will also allow for future expansion of your machine.

Efficiency and precision are crucial considerations in the design of industrial machinery, as they directly impact productivity, product quality, machine lifetime, and the overall effectiveness of your design. By consulting with Dynamic before design of your industrial machinery we can advise you on the critical aspects that will need careful consideration.

- Process Analysis

- Automation and Control Systems

- Sensor Technology

- Component Selection

- Tolerance Analysis

- Motion Control

- Energy Efficiency

- Maintenance Considerations

- User Interface and HMI

- Regulatory Compliance

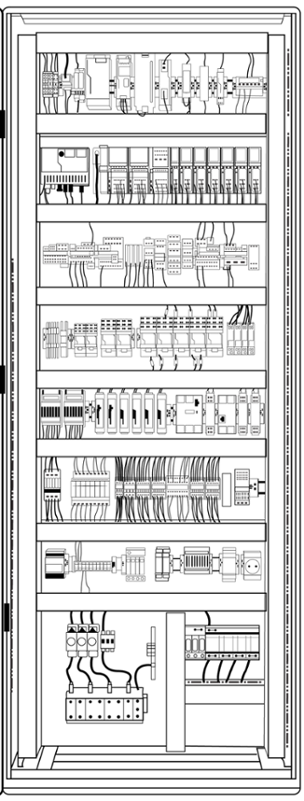

Saving space in an industrial control panel is essential to optimize available space and maximize efficiency. Using compact components such as miniature circuit breakers, slim relays, and smaller or multi-level terminal blocks can help save space in a control panel. Dynamic can assist you with design work such as recommending compact components, planning the layout, using modular designs, utilizing vertical space, optimizing wiring, and using color-coded wiring. Our strategies will help you optimize available space, leading to improved efficiency, reduced costs, and increased productivity.

- Compact Components

- Integrated Systems

- DIN Rail Mounting

- Panel Layout Optimization

- Compact Wiring

- Remote I/O Modules

- Miniaturized Sensors and Actuators

- HMI Integration

- Modular Enclosures

- Multi-Functional Devices

- Compact Communication Protocols

- Heat Dissipation Management