LIGHTING CONTROL PANELS

HIGH QUALITY CONTROL COMPONENTS FOR LIGHTING CONTROL PANELS

Lighting control panels are specialized control systems designed to manage and control lighting in a variety of environments, including commercial buildings, private residences, and public places. The purpose of lighting control panels is to provide a centralized and convenient means of managing lights in an area while optimizing energy efficiency and decreasing expenses.

Typical lighting control panels comprise a variety of controls, such as dimmers, timers, and occupancy sensors, which allow the user to alter lighting levels, schedule lighting changes, and turn lights on and off automatically based on occupancy. The control panels may be automated and combined with other building management systems, including HVAC and security systems, to give a comprehensive and integrated control solution.

In general, lighting control panels play a significant part in the creation of comfortable and energy-efficient lighting environments and are utilized in a vast array of settings, from modest residential to big commercial structures.

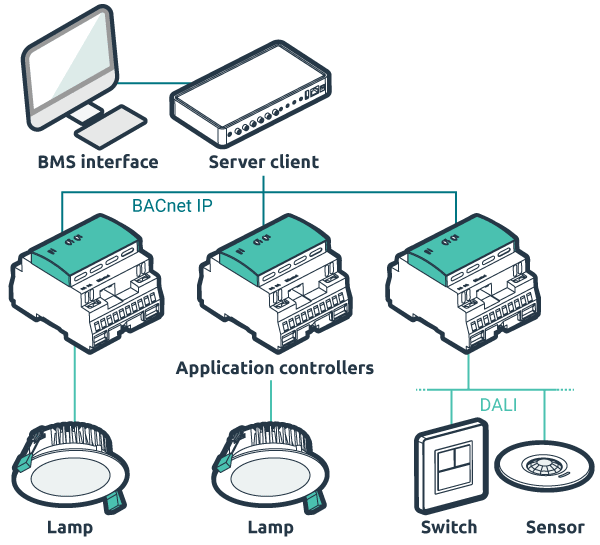

BACnet MS/TP three-point module | Controlling Lighting

Task

You can reduce energy costs by controlling the lighting and blind operation. The lighting level is switched depending on the indoor or outdoor brightness or the use of the rooms. Light scenes should be saved and generated at the push of a button. With the central or decentralized sun protection control, wind, rain, and temperature sensors regulate the position of the blinds and slats depending on the weather and ensure good room lighting conditions.

Solution

We developed the BACnet MS/TP three-point module with six digital inputs, two two-stage relay outputs, and two digital outputs for decentralized switching tasks. It is suitable for B. to switch multi-stage pumps, fans, or blinds. The relay contacts are to be protected by appropriate load-dependent measures. The inputs and outputs can be switched and queried via standard objects using a BACnet client.

Advantages

- Manual control level for the outputs.

- Easier planning and installation of building functions

- High flexibility, as the functions are freely configurable and can therefore be set and readjusted at any time and as required.

- Minimal wiring effort and the I/O components can be stacked using bridging plugs

-

RS485 interface

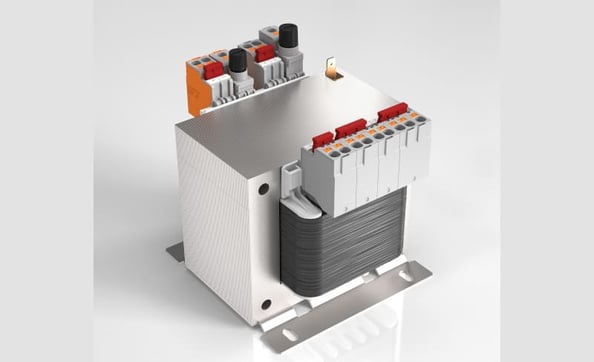

BLOCK’s line of CT series control power transformers is the perfect choice for general-purpose and industrial applications, up to 2500VA.

The most popular application in industrial control panels will be to step-down 480VAC to 120VAC.

Primarily engineered for isolation, lighting, or signal systems, the CT series provides an economical and efficient solution under regular and even abnormal conditions. They ensure a robust design and a continuous electrical supply of your control circuits.

Our TT3 is available for 3-phase and high-power applications up to 600V and ratings from 10kVA to 1MVA.

NEW - Push-In Terminal Block Transformer Connection

Save time on wiring, safe in high vibration applications, no re-torquing required.

No tools, no screws, simply plug in and go, and release with just one click.

Standard Industrial Control Transformers

- Efficient

- Compact

- Voltage Control

- Safety & Isolation

When choosing an industrial control transformer for a control panel, several crucial factors should be considered. The following are some of the most vital considerations:

Voltage and current ratings: When choosing a transformer, ensure it has the proper voltage and current ratings for the intended use. Verify that the transformer can manage the voltage and current needed to power the load.

Frequency: The transformer's frequency should coincide with the electrical supply's frequency.

Insulation class: The transformer needs to have an insulation class appropriate for the control panel's voltage levels and operating conditions.

Efficiency: A more energy-efficient transformer will generate less heat, lowering the possibility of thermal damage and improving reliability.

Size and weight: The transformer's size and weight should suit the control panel's available space and the design's specifications. i.e = autotransformers are small in size but do not provide isolation.

Noise production: Certain transformers may produce electrical noise, which may impair the performance of other electrical parts in the control panel.

Environment: The transformer should be able to function within the control panel's environmental parameters, such as temperature, humidity, shock, and vibration.

Safety: Verify that the transformer complies with all applicable safety regulations and standards for the intended use.

We have the proper transformer for your application; please get in touch.

A switching power supply uses sophisticated electronics to convert AC or DC to a commonly used DC voltage. The most popular application in a din rail mount power supply is to convert 120VAC to 24VDC, although other combinations such as 48V, 12V, and 5V DC are also possible.

Our new PCC series of 24VDC power supplies

Have a robust construction (metal housing) and meet all international safety standards. making the perfect for harsh industrial environments. Additionally, their high-quality components, including the new push-in terminals, ensure stable and consistent voltage output, ensuring long-term performance and minimal downtime. High-quality AC/DC 24V din rail mount power supplies are crucial for industrial control panels' efficient and safe operation.

- Universal AC Input, 85 - 264 VAC

- Universal DC Input, 90 - 374 VDC

- Operating temperature range from -25°C to +70°C, with a safe start-up of the devices guaranteed from -40°C.

- High Altitude is not a problem, guaranteed for 16,000 ft.

- Protection against transient mains overvoltage events

- Voltage withstand up to 4 kV and overvoltage category III

- High efficiency and compact design

- Protection against shock and vibration

- Wide range of safety standards and approvals

- Complies with the latest EMC standards

Let us show you why we should be the power provider for your next industrial control panel build!

Electronic Circuit Breakers!

Branch Circuit protection for voltage levels of 24 VDC. Electronic circuit breakers support selective protection of DC circuits and offer far more tailored protection against overcurrent and short circuits than conventional circuit breakers. eBreakers are available with different tripping characteristics for large machinery to complex systems.

eBreaker are specifically designed for switched mode power supplies and their behavior to supply 24Vdc loads. They split the load current into several channels and reliably monitor overload and short circuits. Defective circuits will be selectively shut down under any type of installation.

They are available in single-channel configurations that can be "bused" together.

And also a compact Multi-channel version up to 8 channels

- Compact Size

- Fixed and adjustable tripping current

- Thermomagnetic and current limiting tripping characteristic

- Remote reactivation for tripped channels

- IO-Link

- NEC Class 2

- UL 2367

- UL 508

Get in touch so we can show you how to benefit from an eBreaker in your next application!

Cable entry frames are used in industrial control panels to provide a secure and organized means for cables to enter and exit. They help protect cables from damage and ensure wires are organized; they can also prevent unauthorized access to the control panel, where a cable gland just be unscrewed.

A tool-free, IP66, or IP54 sealed passage or insertion of assembled and unassembled cables and hoses are made possible by CONTA-CLIP's cable entry systems.

- Cable Protection

- Cable Organization

- Environmental Protection

- Easy to Install

- Cost Effective

.jpg?width=566&height=385&name=KDS-SR_2__780X530%20(1).jpg)

Our KDS solutions for cable entry make it possible to quickly size passage seals for pre-constructed cables. They seal to tightness under IP66 protection class. You can easily change the seal in any cable frame according to the diameter of the hose or cable without disassembling the frame.

• Up to 32 wires in one frame • KDS-FB for flat cables.jpg?width=380&height=259&name=KDS-R_780X530%20(1).jpg)

.jpg?width=381&height=259&name=KDS-FB_780X530_01%20(1).jpg)

• KDSI-SR frames can be assembled outside the panel • KDS-FP frames are expandable

.jpg?width=380&height=258&name=KDS-FP_2_780X530%20(1).jpg)

• KES is a rubber, toolless seal, sealed up to IP66

.jpg?width=380&height=258&name=KES_780X530%20(1).jpg)

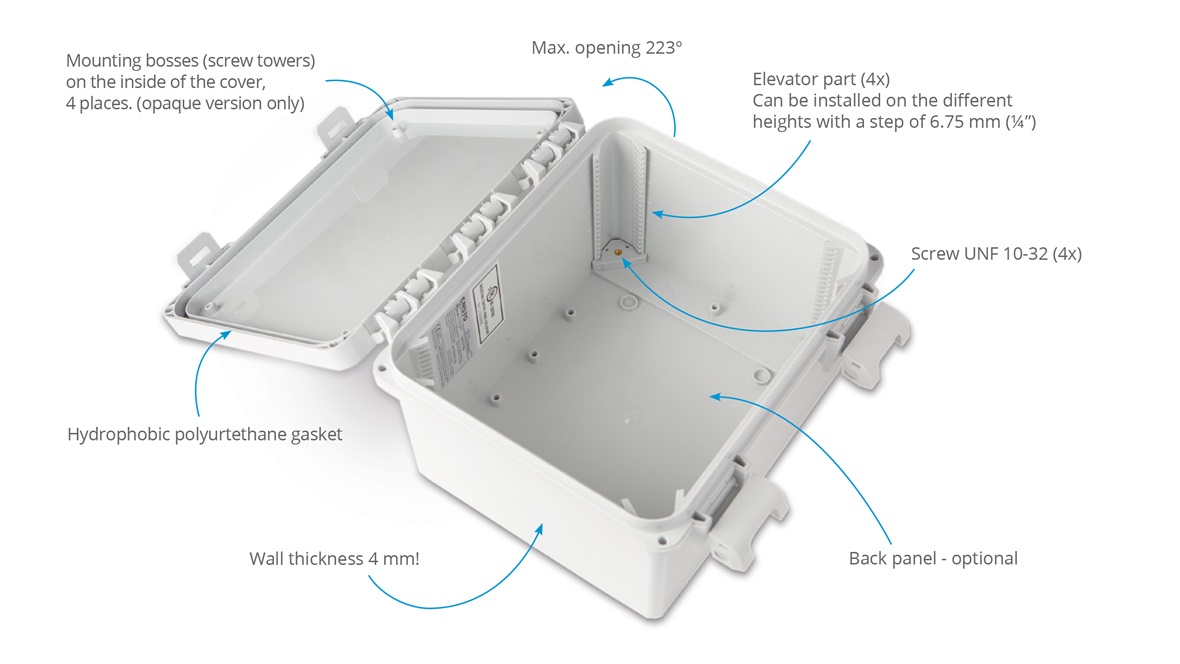

Made from lightweight yet durable materials like fiberglass, polycarbonate, and PVC, these enclosures offer excellent protection against harsh industrial environments, including dust, moisture, chemicals, and extreme temperatures. The Ensto Polybox has a very stylish and modern appearance as well as maintains a rugged look and feel, not like some other brands that feel "cheap and flimsy".

They are available in standard JIC (Joint Industrial Council) sizes from 8x6x4 through 18x16x10

Additionally, these non-metallic enclosures are non-conductive, making them ideal for use in electrical control systems and other applications where electrical safety is a concern. Easy to install and versatile in the number of options available, the Ensto Polybox is perfect for use as an industrial control panel.

Corner Elevator System for raising, lowering, and stacking back panels.

Padlockable nonmetallic latch with only one moving part

Optional Metal Locking Latch

- Corrosion Resistant

- Light Weight

- Temperature Stable

- Cannot Become Electrically Conductive

- No Sharp Corners

- Easy to Modify (no special tools)

- Rugged and Long Life Span

- Overall Very Cost Effective

Dynamic specializes in Electrical Power Components, Industrial Process Control & Electro-mechanical Devices.

Electrical Power Controls

Electrical power controls are devices or components used to regulate, control, and protect the flow of electrical power to various electrical and mechanical systems. These elements include transformers, circuit breakers, contactors, relays, fuses, and motor controls. Their primary purpose is to safeguard electrical systems and equipment from overloading, short-circuiting, and other power-related hazards.

Industrial Process Control

Process control is managing and regulating an industrial process's physical and chemical variables. It uses various control devices, such as sensors, transmitters, controllers, and actuators, to measure and manipulate the process variables. The process control system typically includes monitoring, control, safety, data acquisition, communication, and ensuring that the manufacturing or production process runs efficiently and effectively.

Electro-Mechanical Solutions

Electro-mechanical solutions use a mechanical action to control an electrical function. Electro-mechanical components are essential for an industrial control panel, performing various functions such as switching, sensing, and controlling. They are also used to protect equipment and personnel from electrical hazards and to modify and send electrical signals to other devices in the circuit. Electro-mechanical solutions provide a dependable, efficient, and adaptable method of controlling processes. These are often simple devices without the complexity of internal electronics.

Don't see what you need?

Please contact us!

We have many great partners and would be happy to make a recommendation to a reliable source if we don't have what you need.