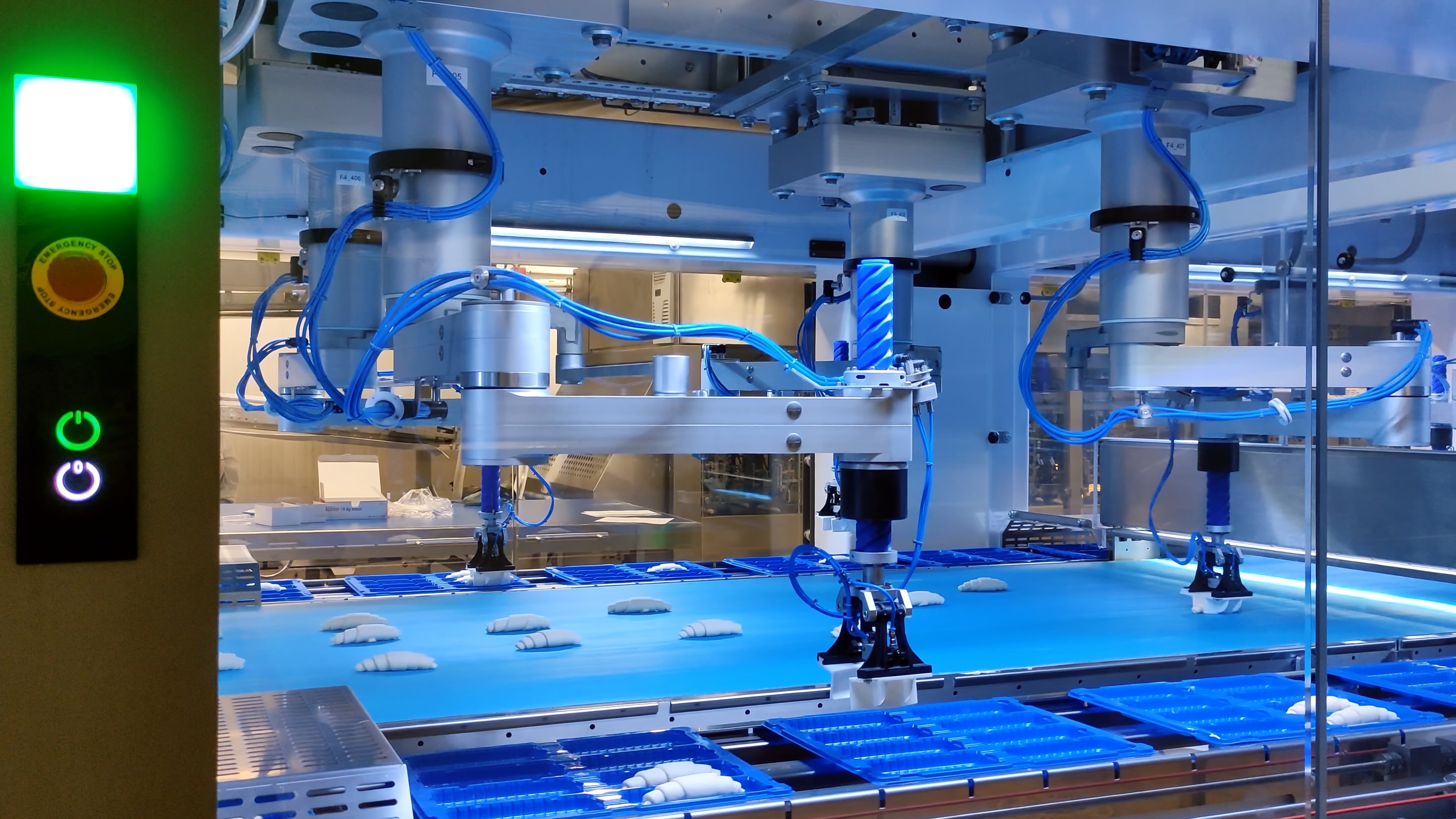

In today's interconnected world, industrial networks ensure seamless communication and operation within manufacturing facilities. These networks enable the transfer of data and control signals between various devices and systems, making them an essential component of industrial automation. To optimize the performance and reliability of your industrial network, one key element you should consider is an Ethernet switch. In this newsletter, we will explore the importance of an Industrial Ethernet Switch in industrial networks, their benefits, and how they can enhance your overall network infrastructure.

What is an Ethernet Switch?

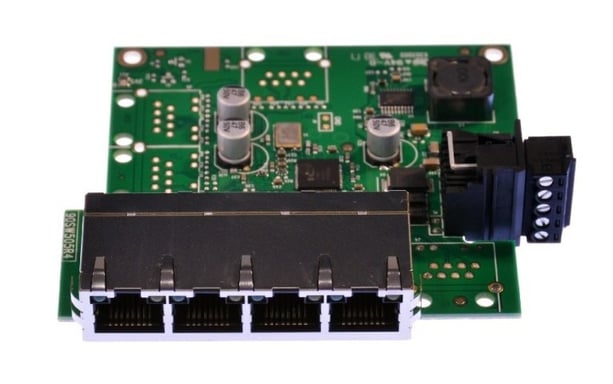

An Ethernet switch is a networking device that connects multiple devices within a local area network (LAN). It operates at the data link layer of the OSI model and enables the transfer of data packets between connected devices. Unlike a hub, which broadcasts data to all connected devices, an Ethernet switch intelligently directs data packets to their intended destination based on the device's MAC address.

The Importance of Ethernet Switches in Industrial Networks

Enhancing Network Performance

Network performance is of utmost importance in industrial environments, where real-time data is critical. Ethernet switches are crucial in optimizing network performance by providing dedicated bandwidth to connected devices. By creating separate collision domains for each port, switches eliminate the risk of network congestion and collisions that can occur in a shared network environment. This results in faster and more reliable data transfer, reducing latency and ensuring real-time responsiveness.

Increasing Network Scalability

As industrial networks grow and evolve, the need for scalability becomes inevitable. Ethernet switches offer the flexibility to expand your network seamlessly. With the ability to connect multiple devices, ethernet switches allow you to add or remove devices without disrupting the entire network. This scalability feature enables easy network expansion to accommodate new devices, production lines, or even entire facilities, providing the agility needed to adapt to changing business requirements.

Improving Network Security

Network security is a critical concern in industrial environments, where the loss or manipulation of data can have severe consequences. Ethernet switches provide enhanced security features to protect your industrial network from unauthorized access and potential cyber threats. Features such as port-based access control, VLANs (Virtual Local Area Networks), and authentication mechanisms help segregate and secure sensitive data and control traffic within the network. Some switches offer advanced security features like MAC address filtering and encryption to strengthen network security further.

Benefits of Ethernet Switches in Industrial Networks

Efficient Data Transfer

One of the primary benefits of Ethernet switches in industrial networks is efficient data transfer. Unlike hubs, which introduce collisions and limit bandwidth, ethernet switches enable simultaneous data transmission between connected devices. Each port on an Ethernet switch has its collision domain, allowing for full-duplex communication and maximizing data throughput. This efficient data transfer ensures the timely delivery of critical information, enhancing overall system performance and productivity.

Reduced Network Congestion

Network congestion can significantly impact performance in industrial networks, where multiple devices generate substantial data traffic. Ethernet switches effectively reduce network congestion by providing dedicated bandwidth to connected devices. Each device connected to an Ethernet switch has a dedicated path, eliminating data collisions and bottlenecks that can occur in shared network environments. This efficient data flow reduces latency and ensures smooth operation during peak traffic periods.

Flexible Network Design

Ethernet switches offer flexibility in network design, allowing you to create a network architecture that best suits your specific requirements. With the ability to connect multiple devices, switches enable the creation of complex network topologies, such as star, mesh, or ring structures. This flexibility allows for implementing redundancy and failover mechanisms to ensure uninterrupted operation in case of network failures. Additionally, switches support using VLANs, which enable logical network segmentation, improving security and simplifying network management.

Choosing the Right Ethernet Switch for Your Industrial Network

Several factors need to be considered when selecting an Ethernet switch for your industrial network. These include network size, bandwidth requirements, environmental conditions, and the specific needs of your industrial applications. Some key features to look for when choosing an Ethernet switch for industrial use include:

- Industrial-grade durability: Industrial Ethernet switches are designed to withstand harsh operating conditions, such as extreme temperatures, dust, and vibrations. Look for switches with rugged enclosures and certifications like IP67 or NEMA 4X for reliable performance in industrial environments.

- High-speed connectivity: Choose switches that support Gigabit Ethernet or higher speeds depending on your network requirements to ensure sufficient bandwidth for data-intensive applications.

- Power over Ethernet (PoE) support: If your network consists of devices that require power, such as IP cameras or wireless access points, consider switches with PoE support. PoE eliminates the need for separate power cables, simplifying installation and reducing costs.

- Management capabilities: For more extensive industrial networks, switches with advanced management features like VLAN support, QoS, and remote monitoring can significantly enhance network control and troubleshooting capabilities.

- Redundancy and failover support: To ensure uninterrupted operation, consider switches that support redundant power supplies, dual homing, or ring topologies for automatic failover in case of network failures.

- Cybersecurity features: In today's increasingly connected world, cybersecurity is critical. Look for switches with advanced security features like port-based access control, MAC address filtering, and encryption to protect your industrial network from unauthorized access and cyber threats.

Installation and Configuration of Ethernet Switches

Once you have selected the appropriate ethernet switch for your industrial network, following proper installation and configuration procedures is essential to ensure optimal performance and reliability.

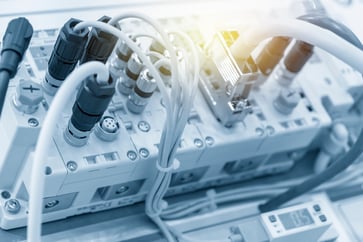

Physical Installation

The physical installation of an Ethernet switch involves mounting the switch in a suitable location and connecting the necessary cables. Consider the following guidelines during the installation process:

- Choose a location that provides adequate ventilation and protection from environmental factors such as dust, moisture, and temperature extremes.

- Mount the switch securely using appropriate hardware, ensuring stability and preventing accidental disconnection.

- Connect the necessary Ethernet cables to the switch ports, ensuring proper alignment and secure connections.

Network Configuration

After the physical installation, the ethernet switch must be configured to suit your network requirements. Follow these steps for successful network configuration:

- Access the switch's management interface using a web browser or dedicated management software.

- Configure the switch's IP address, subnet mask, default gateway, and other network parameters to ensure proper communication within the network.

- Create VLANs or other logical network segments to improve network security and manageability.

- Set up Quality of Service (QoS) policies to prioritize traffic and ensure optimal performance for critical applications.

- Configure any additional features or settings required for your specific network environment, such as port mirroring, link aggregation, or redundant path configurations.

Best Practices for Ethernet Switch Deployment

To maximize the benefits of Ethernet switches in your industrial network, consider implementing the following best practices:

Network Segmentation

Segmenting your industrial network into smaller, isolated subnets or VLANs can enhance security and performance. By logically separating different departments, production lines, or devices, you can control access, limit the impact of network failures, and optimize data flow within each segment.

Redundancy and Failover

Implementing redundancy and failover mechanisms is crucial to ensure uninterrupted operation in industrial networks. Redundant power supplies, dual homing, or ring topologies can provide automatic failover in case of network failures, minimizing downtime and maintaining system availability.

Quality of Service (QoS)

Prioritizing network traffic based on its importance is essential in industrial networks. Setting up Quality of Service (QoS) policies allows you to allocate bandwidth and prioritize critical applications or services, ensuring their performance even during peak network traffic.

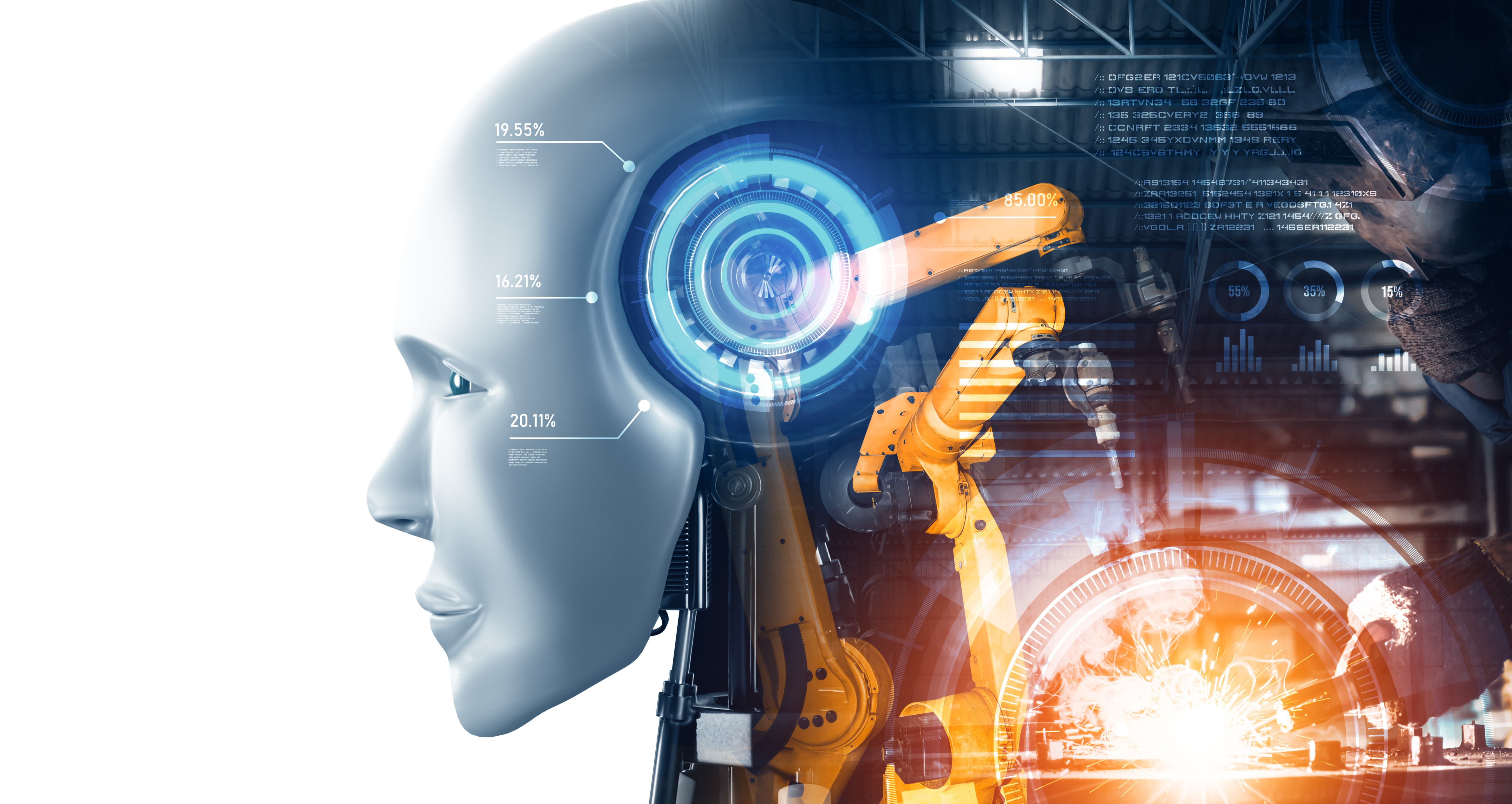

Future Trends in Industrial Ethernet Switches

As technology continues to evolve, so do industrial Ethernet switches. Several trends are shaping the future of industrial Ethernet switches, including:

- Increased bandwidth requirements: As industrial networks become more data-intensive, the need for higher bandwidth continues to grow. Industrial Ethernet switches supporting multi-gigabit speeds or even 10 Gigabit Ethernet are becoming more prevalent to meet these demands.

- Integration of advanced technologies: Industrial Ethernet switches incorporate advanced technologies such as Time-Sensitive Networking (TSN) and Power over Ethernet (PoE) to enable real-time communication and power delivery to connected devices.

- Enhanced cybersecurity: With the rise in cyber threats targeting industrial networks, Ethernet switches are incorporating advanced security features like deep packet inspection, anomaly detection, and network segmentation to protect against unauthorized access and data breaches.

- Integration with Industrial Internet of Things (IIoT): Industrial Ethernet Switches are becoming more IoT-ready, offering features like MQTT (Message Queuing Telemetry Transport) support, cloud connectivity, and edge computing capabilities to enable seamless integration with IIoT platforms.

Check out our Industrial Networking products

Conclusion

In conclusion, integrating ethernet switches in industrial networks is essential for optimizing performance, scalability, and security. These switches enable efficient data transfer, reduce network congestion, and provide flexibility in network design. By choosing a suitable ethernet switch for your industrial network, following proper installation and configuration procedures, and implementing best practices, you can ensure a reliable and robust network infrastructure that meets the demands of your specific industrial applications. As technology advances, industrial ethernet switches will play an increasingly vital role in supporting the evolving needs of industrial automation and digital transformation.