In today's rapidly advancing world of technology, electrical enclosures play a crucial role in safeguarding electronics in various industries. These carefully engineered boxes protect sensitive equipment from electrical control panels to telecommunications, IT systems, utilities, and the Internet of Things (IoT). Failure to select the proper electrical enclosure can lead to significant damage to equipment, operational losses, and even endanger lives. Therefore, device designers and electricians must understand the different types of electrical enclosures and choose the most suitable one for their specific application.

Understanding NEMA Ratings for Electrical Enclosures

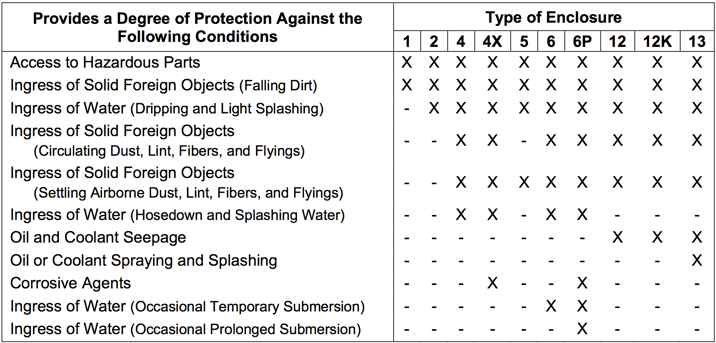

When discussing the various types of electrical enclosures, referring to the enclosure ratings defined by the National Electrical Manufacturers Association (NEMA) is common. The NEMA rating system establishes the standards for electrical enclosures in North America, ensuring safety and reliability.

The purpose of NEMA ratings is to indicate an electrical enclosure's ability to withstand specific environmental conditions and hazards. Engineers can rely on these ratings to select an enclosure that will perform optimally in their desired application.

Check out our various types of NEMA Electrical Enclosures

NEMA Type 1 Electrical Enclosure: Basic Indoor Protection

NEMA Type 1 enclosures offer the most basic level of protection among all NEMA-rated enclosures. Designed for indoor use, they provide slight protection against light dust, dirt, and accidental contact with electrical equipment. These enclosures find typical applications in various industries, such as housing variable-frequency drives in standard indoor locations.

While NEMA Type 1 enclosures are cost-effective solutions for protecting electronics in non-hazardous indoor environments, it is essential to consider factors such as excess moisture and heat generated by the equipment. In settings with high internal heat loads, venting accessories and custom cutouts can be utilized to prevent overheating and ensure the longevity of the electrical components.

NEMA Type 3 Electrical Enclosures: Weatherproof Outdoor Protection

NEMA Type 3 enclosures are designed for both indoor and outdoor use. However, they are primarily utilized as outdoor electrical enclosures because they can withstand falling dirt, rain, snow, sleet, and external ice formation. While unsuitable for extreme weather conditions, these enclosures are reliable outdoor junction boxes, protecting electrical wiring connections and cables.

Engineers must carefully consider the exact location and material of their NEMA Type 3 enclosure. ABS plastic enclosures, for example, are not recommended for direct sunlight exposure as they may warp. Polycarbonate enclosures, on the other hand, offer durability, cost-effectiveness, and UV resistance, making them a safer choice for outdoor environments.

NEMA Type 4 Electrical Enclosures: Watertight Industrial Protection

NEMA Type 4 enclosures provide excellent protection against harsh weather conditions compared to NEMA Type 3R enclosures. These enclosures are particularly suitable for industrial applications with essential watertight features, such as protecting outdoor electrical systems, wire splices, circuit breakers, and mounted telecommunications equipment.

One significant difference between NEMA Type 4 and 3R enclosures is the level of protection against splashing and hose-directed water. NEMA Type 4 enclosures offer a higher degree of resistance to water ingress, thanks to their protective gaskets. Additionally, NEMA 4 aluminum enclosures provide natural electromagnetic (EMI) and radio frequency interference (RFI) shielding, making them ideal for applications in the telecommunications industry.

NEMA Type 4X Electrical Enclosures: Corrosion-Resistant Outdoor Protection

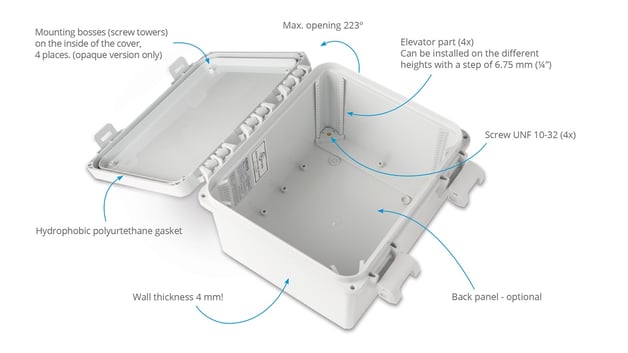

NEMA Type 4X enclosures offer the same level of protection as NEMA Type 4 enclosures but with enhanced resistance to corrosion. These weatherproof electrical boxes are commonly used in applications exposed to excessive moisture, intense water spray, and corrosive chemicals.

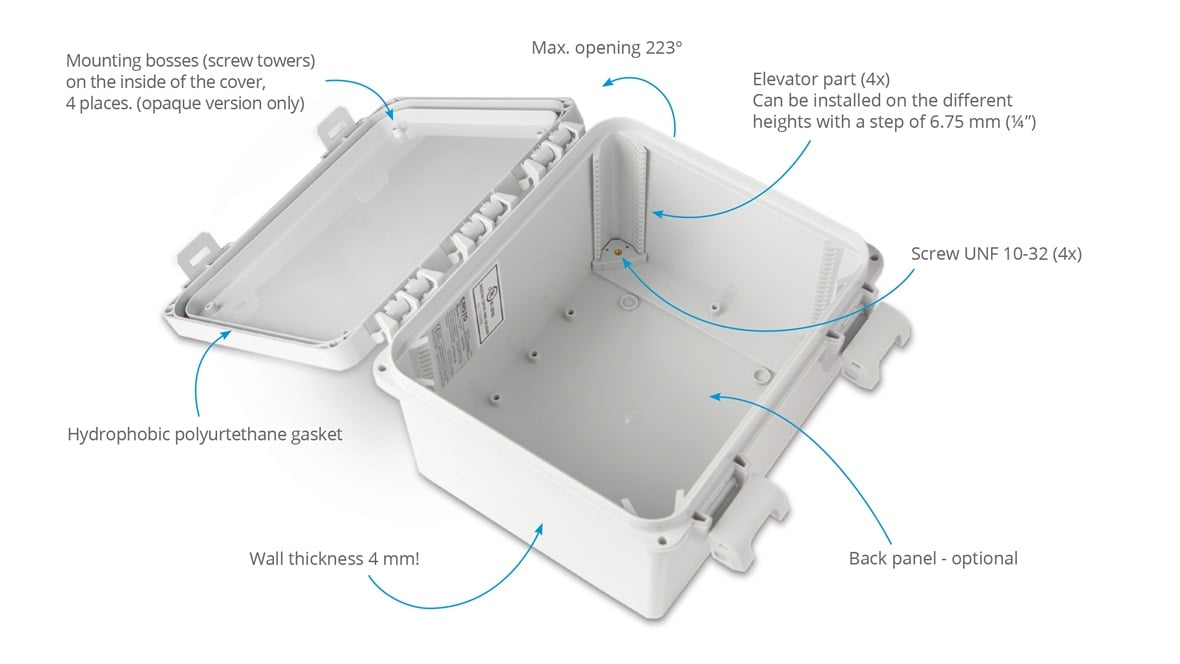

Excess moisture can cause corrosion in electrical systems, damaging sensitive components. NEMA Type 4X enclosures are watertight, preventing condensation from harming electrical equipment. In some applications, the ability to make modifications onsite is crucial. Enclosures with knockouts, such as the Ensto Cubo S series plastic enclosures, provide wiring and cabling flexibility, saving electrical technicians time and money.

NEMA Type 6 Electrical Enclosures: Submersible Protection

NEMA Type 6 enclosures are designed for indoor and outdoor use, offering protection against occasional temporary submersion in water. These weatherproof enclosures find applications in various industries, including electric vehicles and maritime transportation.

Engineers can rely on NEMA Type 6 enclosures to protect against accidental contact with electrical equipment, wet environments, falling dirt, external ice formation, and water ingress during temporary submersion. These enclosures are often used in power plants and alternative energy applications, where durability and resistance to extreme environments are crucial.

NEMA Type 6P Electrical Enclosures: Submersible Corrosion-Resistant Protection

NEMA Type 6P enclosures provide the same level of protection as NEMA Type 6 enclosures but with added resistance to prolonged submersion in water and increased corrosion resistance. These enclosures are among the most durable types available and are commonly used in underground mines, remote caves, and offshore environments, which are highly corrosive.

Aluminum and polycarbonate are popular for NEMA Type 6P enclosures due to their corrosion resistance and durability. Aluminum enclosures offer natural EMI/RFI shielding, while polycarbonate enclosures provide resilience and performance comparable to aluminum.

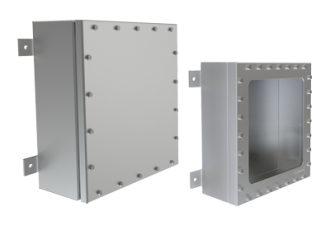

NEMA Type 7 Electrical Enclosures: Explosion-Proof Protection

NEMA Type 7 enclosures are designed for indoor hazardous locations classified as Class 1, Division 1, Groups A, B, C, or D. These hazardous environments, commonly found in chemical plants and oil and gas facilities, contain combustible gases that can cause internal explosions.

Explosion-proof enclosures, such as NEMA Type 7 enclosures, are engineered to contain explosions without causing external damage. With the increasing deployment of Internet of Things (IoT) systems in hazardous environments, NEMA Type 7 enclosures are becoming more popular to protect equipment from dust, dirt, water, and potential explosions caused by combustible gases.

NEMA Type 12 Electrical Enclosures: Indoor Protection against Dust and Non-Corrosive Liquids

NEMA Type 12 enclosures protect against water drips, falling dirt, dust, and non-corrosive liquids for indoor applications. While they offer superior protection compared to NEMA Type 1 and 2 enclosures, they are less protective than outdoor enclosure types like NEMA Type 4X and NEMA Type 6P.

Dust can be detrimental to electrical equipment, especially when mixed with other materials that make it combustible and prone to explosion. NEMA Type 12 enclosures are built to prevent the ingress of dust, dirt, and dripping and splashing water, ensuring the smooth operation of automation equipment and other electrical devices commonly found in machining, manufacturing, and industrial applications.

Choosing the Right Material for Electrical Enclosures

In addition to NEMA ratings, the choice of enclosure material significantly impacts the performance and functionality of electrical enclosures. Several common materials are used to manufacture enclosures, each with advantages and disadvantages.

Polycarbonate Plastic

Polycarbonate plastic enclosures are cost-effective alternatives to metal enclosures. They offer excellent impact resistance, versatility, and suitability for indoor and outdoor applications. These enclosures are commonly used in the IT industry, desktop electronics, and electrical applications with non-metallic cables.

ABS Plastic

ABS plastic is an affordable material known for its impact and heat resistance. While not as durable as polycarbonate, ABS plastic enclosures are commonly used for indoor applications that require basic protection.

Aluminum

Aluminum enclosures are highly durable and suitable for both indoor and outdoor use. They can withstand high temperatures and offer natural resistance to corrosion, making them ideal for applications that require grounding for metal conduit or metal-sheathed cable. Additionally, aluminum enclosures provide electromagnetic and radio frequency interference shielding.

Stainless Steel

Stainless steel enclosures are fire-resistant, suitable for wet environments, and have an attractive appearance. However, they are more expensive than other enclosure materials. Stainless steel is commonly used in marine environments due to its corrosion resistance, although aluminum and polycarbonate enclosures offer similar advantages.

Carbon Steel

Carbon steel enclosures are solid and cost-effective options. However, they are highly susceptible to corrosion, making them less suitable for coastal regions unless they have a protective powder coating applied.

Conclusion

Electrical enclosures are critical components for protecting sensitive electronic equipment in various industries. By understanding the different types of enclosures and their applications, engineers and electricians can ensure the safety and reliability of electrical systems. Factors such as NEMA ratings, environmental conditions, and material selection should be carefully considered to select the most appropriate enclosure for each unique application. With the wide range of options available, including polycarbonate, ABS plastic, aluminum, stainless steel, and carbon steel enclosures, there is a solution to meet the specific needs of any electrical project.

Our enclosures are UL Listed for dependable performance, and we offer customization options to create enclosures with custom cutouts and printing. If you need assistance selecting a suitable electrical enclosure for your application, contact us today to explore our full range of NEMA-rated enclosures.

Check out our various types of NEMA Electrical Enclosures