The first alternator was built in 1835 in Paris, France, by Hippolyte Pixii. It was a device which utilized a magnet rotated by a hand crank to produce what is called Alternating Current, or AC. However, scientists at the time were more interested in Direct Current (DC). The prevalence of DC got a substantial boost in the late 1880s when Thomas Edison built a DC power system for his New York City neighborhood. Then, George Westinghouse bought patents for AC power transformers and motors from great inventors of the time such as Nikola Tesla. This battle between electrical distribution methods caused the war of the currents, and there was switching back and forth between DC and AC, before AC eventually won as the more viable power distribution method. Even though DC high voltage is very stable and has very low loss, the underlying problem was that Direct Current was not easily converted to higher or lower voltages.

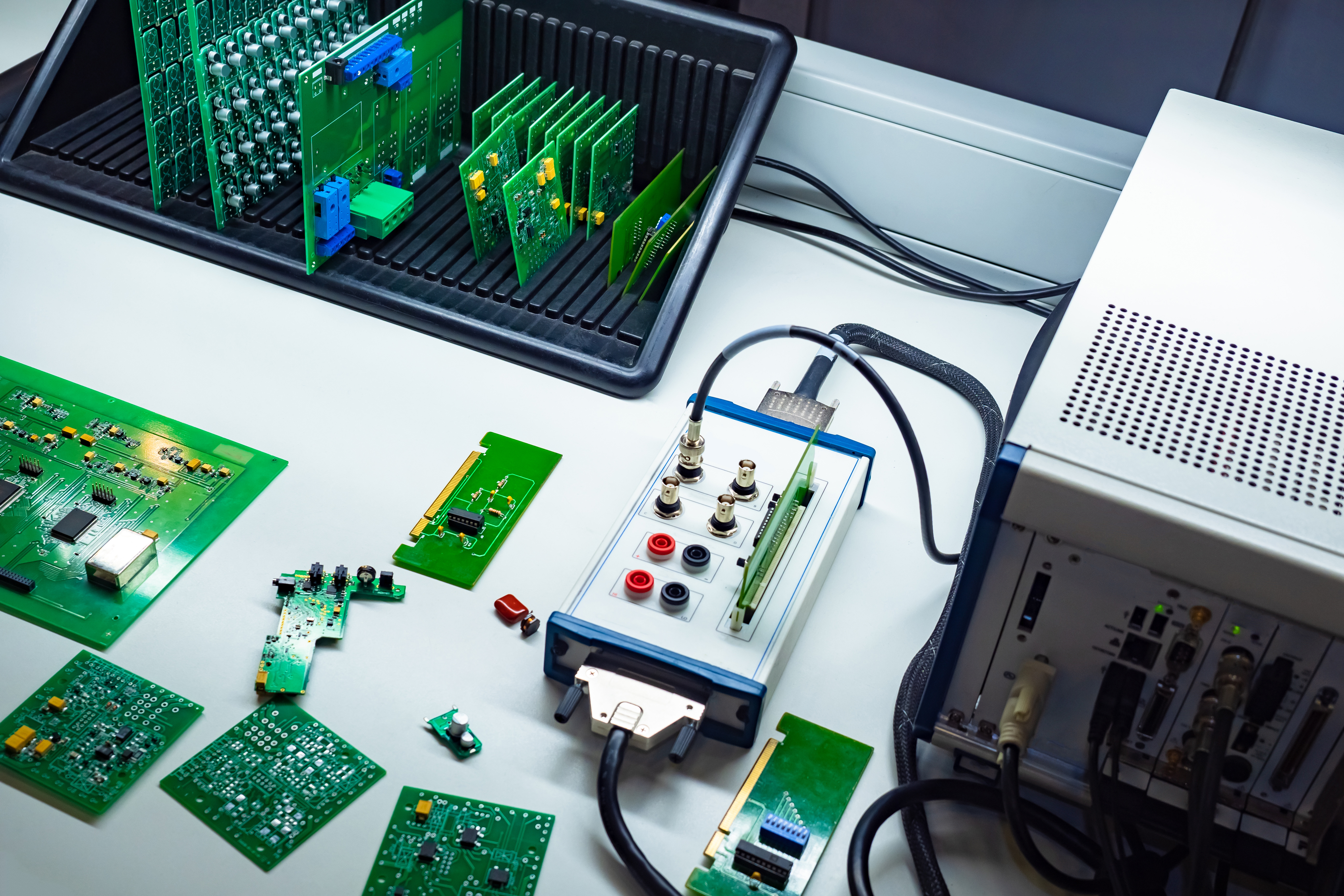

In recent years DC power has made a bit of a comeback. The advancement of Computers, LED lighting, Solar systems and EV’s have led to useful new methods as well as lower costs of converting DC to higher and lower voltages. There are only a handful of companies who specialize in DC energy so when you have these types of special applications you need specialty suppliers. In this blog, we will discuss DC electrical measurement in rugged industrial environments. At Dynamic we understand the challenges that DC high voltage and DC high current present, which is why we focus on suppliers who emphasize quality, accuracy, precision, and a deep knowledge of product applications and how they will be used.

Many instruments and measuring devices can accurately measure small DC currents up to 3A, however very few devices are capable of accurate measurements of DC currents in ranges that extend beyond 50A. The accuracy of the measurement and cost are the fundamental challenges for measuring high DC current and voltages. The knowledge of safety categories and the difference in Dielectric Withstand vs. Isolation Voltage levels are often not understood until there is a problem. We hereby present you with some of the more modern devices for industrial DC measurement and control, and the necessary techniques and tips for device selection. Let us begin with the following quick DC voltage measurement tutorial and what you should be looking for in your DC electrical components.

Many instruments and measuring devices can accurately measure small DC currents up to 3A, however very few devices are capable of accurate measurements of DC currents in ranges that extend beyond 50A. The accuracy of the measurement and cost are the fundamental challenges for measuring high DC current and voltages. The knowledge of safety categories and the difference in Dielectric Withstand vs. Isolation Voltage levels are often not understood until there is a problem. We hereby present you with some of the more modern devices for industrial DC measurement and control, and the necessary techniques and tips for device selection. Let us begin with the following quick DC voltage measurement tutorial and what you should be looking for in your DC electrical components.

An AC current transducer is a simple device that works off the magnetic field created by flow of the AC current, magnetic flux. Using the same magnetic transfer principle, this makes AC voltage extremely easy to isolate and measure via a simple transformer.

An AC current transducer is a simple device that works off the magnetic field created by flow of the AC current, magnetic flux. Using the same magnetic transfer principle, this makes AC voltage extremely easy to isolate and measure via a simple transformer.

DC Current, on the other hand, does not create this magnetic flux. Therefore, it requires some real skill to get a safe and accurate measurement.

This is where DC current and voltage transducers come in. They are designed to provide a linear output signal which is proportional to a sensed DC current or voltage. Perhaps, the most overlooked part of selecting an industrial DC measurement device is a deep understanding of what the external influences will do to your measurement. At minimum you need to understand:

- Electrical Requirements

- Power Source

- Peak Measurement and Signal Clipping

- Response Time

- Rate of Change and Common Mode Voltage Transients (dv/dt)

- Series Resistance

- Space Limitations (mechanical)

- Thermal Conditions (both resistance and environmental influences)

- Shock and Vibration

- Proximity to other Conductors and Magnetic Fields

- Regulatory Compliance (UL, IEC, CSA, CE, etc.)

Having a detailed understanding of the application is the first step. After that, you should give consideration to your technical know-how of the device you select, its economic advantages, and what that means for your measurement. Some other considerations on device selection are:

- Safety via high isolation and fault insulation levels (Electrical Separation)

- Accuracy and signal transmission speed

- A high cut-off frequency (Bandwidth) of > 5 kHz

- Reaction time - The inherent delay (t90) should not exceed 100 µs

- Device efficiency by reducing common mode interferences.

You should also know that there are certain systems for current or battery charge measurements that can be designed to include built-in data acquisition attributes using suitable amplifiers, filters, analog-to-digital converters (ADCs), and many more. Typically, a current sensor would sense the current, and the output of a current sensor would require a circuit that isolates and converts its output into a usable form. Then to reduce electromagnetic and radio frequency interference, this signal might be filtered, amplified, and digitized. These additions to the circuit all affect the resolution and delay in the measurement at the output.

Perhaps you are well versed in DC current and voltage control because of your involvement in areas like DC motors or Drives and Energy Transmission. Or maybe you just need to convert AC to DC current and voltage before applying them, since this is how a majority of industrial machines and appliances operate anyhow. The typical applications where you will need to understand high voltage DC phenomena include:

- Large Motor Drives (shunt monitoring and direct motor measurements)

- Cycle Converter

- Automatic Voltage Regulator

- Excitation Systems

- Generators

- Rectifier

- Inverter

- DC Link

- Power Transmission and Distribution

- Transmission

- Distribution

- Collector

- Rectifier & Inverter - DC Link

- Switching

- Green Energy, Smart Grid & Electrical Substations

- Medium to High Voltage Circuit Breakers

- DC switchgear

- DC power supplies

- Battery Charging and Monitoring

- UPS Systems

- Cathodic Protection (monitoring shunts)

- Protective Relay Applications

- Power Simulation, Monitoring, and Testing

At Dynamic we are always staying up to date on innovations and new technology. We hope you found our information about measurement devices for DC voltage and current useful. The devices we represent are thoughtfully designed with consideration to the above-mentioned properties, and will improve your DC electrical measurement tasks.

If you found these tips about DC current and voltage measurement useful? Read about control and switching of DC current here. Also keep an eye out for our next blog where we dive into AC power quality, Power connectors, and PDU's. You can also stay in touch with us by signing up for our newsletter and receive updates when we have promotions or new blog posts.

If you have a DC measurement application to discuss please get in touch!