You’ve probably been in a situation when you were faced with selecting electrical components to terminate your wires. This can sometimes feel like a daunting task – especially if you are dealing with expensive electronics and measuring devices within your industrial equipment. You are not alone! We have had a lot of engineers tell us how they wait until the last minute to review specifications or just use whatever was in stock at the time, leading to problems later down the road.

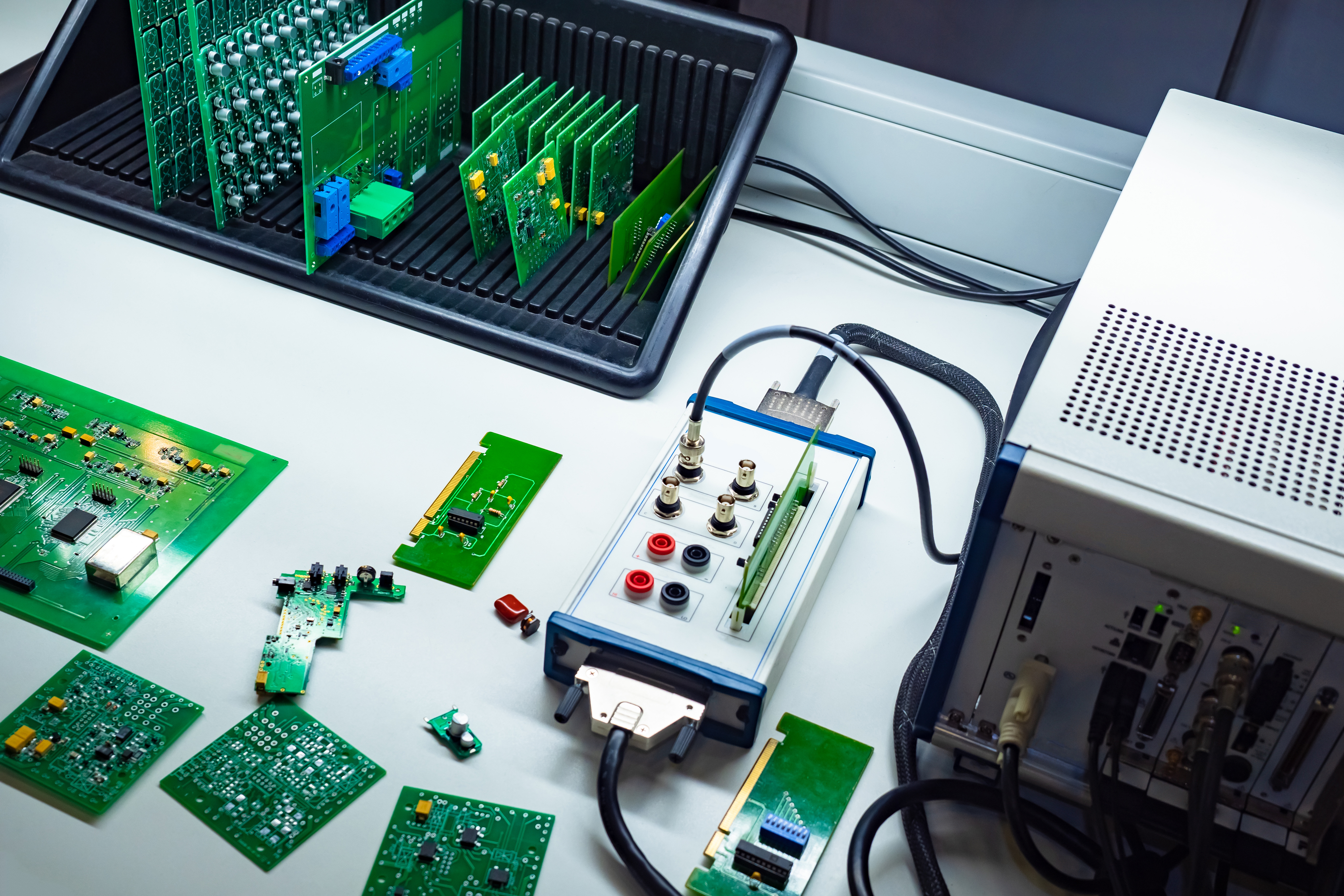

This begs the question, what are the important things you should be considering when specifying a terminal block? Selecting some of the major components, like PLC’s and electronics, is a hard enough task, so choosing the proper electro-mechanical items is often overlooked. Terminal Blocks (also known as terminal strips and sometimes used interchangeably) don't have to be something you put off to be the last decision, that sometimes complicates the issue.

Terminal strips and DIN rail mount blocks are not tricky items, but they do come with a huge variety of specifications and packages. Perhaps this is where some of the challenges arise. Needless to say, terminal blocks are extremely important electrical components, but they are treated as mundane or don’t matter until you have a problem.

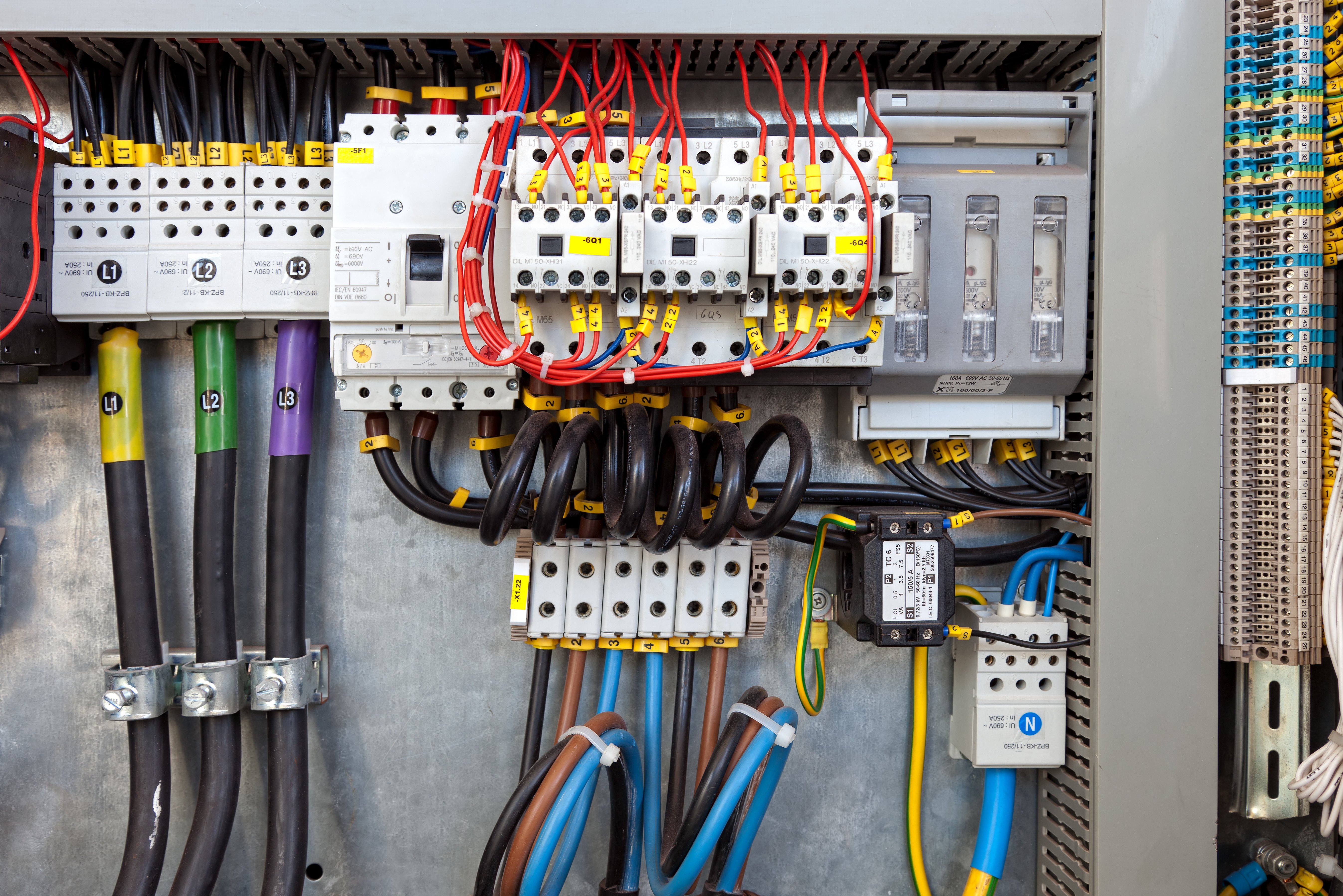

For one, they increase safety by grounding, isolating, and protecting the other components in the electrical cabinet. They are also typically finger-safe connections that prevent electrical shock. Furthermore, terminal blocks provide test points, which add even more functionality and safety to the circuit.

The task of selecting a terminal block seems simple, but what if you choose an improper terminal block? While not only could this be a dangerous electrical situation, the consequences could be much higher. For example; shutting down an entire production line, manufacturing and productivity losses, and the over-all loss of faith a customer has in your system, or worse, your company. All of this over something that is deemed simple or unimportant. It is therefore essential to choose a terminal block that perfectly matches the application requirements.

How do you choose a perfect match for your system? This is a question that is often on the minds of equipment designers. To choose the right terminal block for your system, you first need to understand the purpose of terminal blocks and learn about their types. A terminal block is a device that enables connectivity between multiple wires and circuits and the connections are enclosed in an insulated housing. It can be regarded as the component that forms the backbone of automation and electrical control systems. Since terminal blocks are used in various applications, they come with different types of wire termination connections. These include push-in, screw-in, spring cage, insulation displacement, and lug connections ... to name a few.

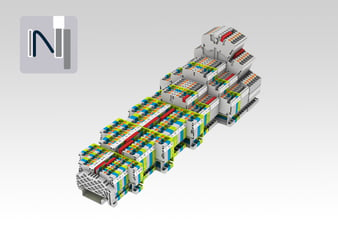

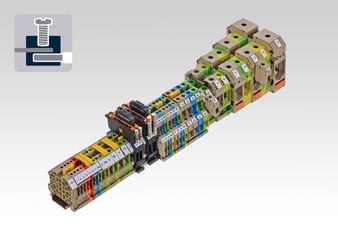

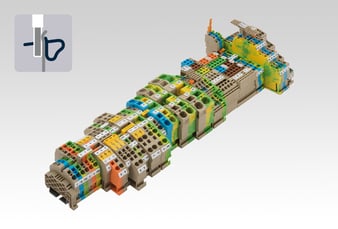

Primarily, there are three structured types of terminal blocks:

- Single-feed through terminal blocks: These are simply used to safely connect two wires together, and can be referred to as a wire-to-wire connection.

- Dual-level terminal blocks: Just as the name implies, this class of terminal blocks has another level of connection terminal stacked on top of the first one. They are especially needed for saving space, simplifying wiring and suitable for increasing current capacity.

- Triple-level terminal blocks: These have three levels of contacts. They are more like an extended version of double-level terminal blocks with an added level at the top. One advantage of these multi-level blocks is that multiple connections can be made in the same block. Many times these are used when you have several 3 or 4 wire sensors to connect.

DYK, you can color code your terminal block to match your wiring?

Using colored terminal blocks can sometimes eliminate the need for additional labeling too.

Colored terminal blocks can indicate to the end user:

- HIGH current or VOLTAGE

- AC or DC input and output

- Signal distribution wires vs. Power distribution wires

- Grounding and Earthing

Now that you know the terminal block types, lets discuss the importance of the application and where they will ultimately end up.

Following the steps below can help you speed up and simplify the process of building a terminal block strip.

How to Select the right Terminal Block for your project

The very first step is to determine which type of connection suits your requirements. If you choose a screw connection, you may have to write a torque specification and re-check the connection after it has experienced vibration (like shipping) or been in the field for certain periods of time. Push-In and Spring cage do not need this.

Will there be high currents that could cause a spring connection to heat and cool regularly? In a spring cage block this could cause the metal to reverse-anneal and weaken to the point where a light tug will remove the wire. You need to make sure the spring is steel reinforced.

Will it have repeated use? How many times must it be operated and still make a reliable connection? IDC cannot be continually disconnected and reconnected without cutting/shortening the wire, which wears out the blades. Push-in and spring have a limited actuation life as well, which makes the design and materials very important.

These are a few additional things to consider to choose the correct type of terminal block.

Determine Specification Requirements

Determine the electrical specifications needed according to your system. As already discussed, terminal blocks come in a variety of sizes, specifications and colors. You should choose a terminal block and DIN Rail that will fit well within the space you have and has enough clearance above and below for the terminals, accessories and the bend radius of the wires being connected. Always make sure you have met the proper agency approvals for safety and end user location. Electrically you must consider the maximum voltage, current rating and the wire sizes used in your system. The wire size can be calculated through the current rating, and It also depends upon the type of conductor being used: whether it is solid or stranded. The contact material of your terminal block and wires of dis-similar metals can corrode and aluminum on copper will loosen if not properly treated. If it were a signal reading like a thermocouple the metal has to match the same metal type as the wire, otherwise the measurement is no good. Review of the physical environment as well as the temperature ratings will also need to be done. Then lastly consider that a technician may have to get to these after install, so the actuation points to remove and re-attach wires should be easily accessible and easy to see.

Choose Compatible Accessories

After you have chosen a suitable terminal block housing, select jumpers, end covers and end brackets that match your Din rail requirements. Make sure your jumpers are also rated for the full current your conductor needs to carry, often they do not. In some cases, terminal blocks can contain fuses or circuit breakers for circuit protection, indicator lights for easy monitoring, as well as diodes, resistors, capacitors or other electronics for enhanced safety.

After you have chosen a suitable terminal block housing, select jumpers, end covers and end brackets that match your Din rail requirements. Make sure your jumpers are also rated for the full current your conductor needs to carry, often they do not. In some cases, terminal blocks can contain fuses or circuit breakers for circuit protection, indicator lights for easy monitoring, as well as diodes, resistors, capacitors or other electronics for enhanced safety.

You might also be interested in using a pluggable terminal block since they offer better control over a large group of terminals, they save space and make for easy disconnecting, testing and service. These terminals are mounted and configured together on a DIN Rail in the same way, but they allow you to disconnect the complete stack by removing just one plug.

Determine Rail Length

To calculate rail length, first, calculate the total density per foot of all types of blocks and their quantity. Now, add the width of end covers and end brackets too. Also add the width of separators; if there are any. Since we also need to accommodate tolerance, add 0.0008” per terminal. And don’t forget to add at least 0.5” to your calculations for each rail in order to accommodate rail mounting screws.

To calculate rail length, first, calculate the total density per foot of all types of blocks and their quantity. Now, add the width of end covers and end brackets too. Also add the width of separators; if there are any. Since we also need to accommodate tolerance, add 0.0008” per terminal. And don’t forget to add at least 0.5” to your calculations for each rail in order to accommodate rail mounting screws.

Sounds difficult? It isn’t. You might want to go over everything one more time. Terminal blocks are a robust and efficient devices only when chosen properly. Improper selection of terminal blocks might not perform well and cause unwanted complications. It is recommended to consult with a professional to review your applications requirements or help you write a proper terminal block specification. Before selecting the next terminal block for your system consider giving the team at Dynamic a call.

You can review our Terminal Blocks in more detail here:

Screw

Push-In

Spring

Power Distribution

Power Distribution Panel Feed Through

Panel Feed Through

Barrier or Terminal Strips

PCB Terminal Blocks

Need a sample? Just ask or give us some project details and we will get you some evaluation units!