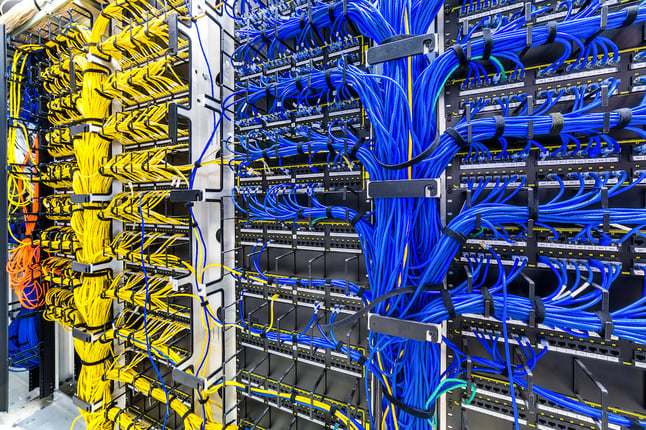

In today's digital age, reliable and uninterrupted connectivity is crucial for businesses across various industries. Industrial Ethernet cables ensure data can be transmitted efficiently and securely in industrial environments. These cables are designed to withstand harsh conditions such as extreme temperatures, moisture, vibration, and electromagnetic interference.

Importance of selecting the suitable Industrial Ethernet Cables

Selecting the right industrial Ethernet cables is paramount to ensure uninterrupted connectivity and optimal performance. The right choice of cable can lead to better signal quality, data loss, and network downtime, which can have severe implications for industrial operations. Businesses can avoid costly disruptions and ensure smooth operations by investing in high-quality and suitable Ethernet cables.

Understanding the different types of Industrial Ethernet Cables

Several types of industrial Ethernet cables are available in the market, each with unique characteristics and applications. The most common types include:

- Cat 5e and Cat 6 Cables

Cat 5e and Cat 6 cables are widely used in industrial environments. They offer excellent performance and support up to 1 Gbps data transmission speeds. These cables are suitable for most industrial applications that require high-speed and reliable connectivity. - Fiber Optic Cables

Fiber optic cables are ideal for long-distance data transmission and environments with high electromagnetic interference. They offer superior bandwidth capabilities and support up to 100 Gbps data transmission speeds. Fiber optic cables are also immune to electromagnetic interference, making them highly reliable in industrial settings. - Industrial Ethernet Cables with Armored Jacket

Industrial Ethernet cables with armored jackets protect against physical damage, such as crushing, impact, and abrasion. These cables are commonly used in rugged industrial environments with a higher risk of mechanical stress.

Factors to consider when selecting Industrial Ethernet Cables

Choosing the right industrial Ethernet cables requires careful consideration of several factors. These factors include:

- Environmental Requirements

With extreme temperatures, moisture, chemicals, and vibration exposure, industrial environments can be challenging. It is essential to select Ethernet cables designed to withstand these conditions. Look for cables resistant to temperature variations, moisture ingress, and chemical exposure. - Transmission Speed and Bandwidth Requirements

Consider the required data transmission speed and bandwidth for your industrial application. Higher transmission speeds may require cables with higher performance specifications, such as Cat 6 or fiber optic cables. Ensure the selected cables can support the desired data rates without degradation. - Shielding Requirements

Industrial environments are often prone to electromagnetic interference (EMI) and radio frequency interference (RFI). Choose Ethernet cables with appropriate shielding to minimize the impact of EMI and RFI. Shielded cables can provide better protection against external interference, ensuring reliable data transmission.

Assessing the environmental requirements for Industrial Ethernet Cables

Industrial Ethernet cables are subject to environmental conditions impacting their performance and longevity. It is crucial to determine the specific environmental needs of your industrial application before selecting the appropriate cables.

Temperature Range

Industrial environments can experience extreme temperatures, both high and low. Some applications may require cables that can withstand temperature ranges from -40°C to 85°C or even higher. Ensure that the selected cables have the necessary temperature ratings to operate reliably in your environment.

Moisture and Chemical Resistance

Moisture and chemical exposure can damage Ethernet cables, leading to signal loss and reduced performance. Look for cables with moisture-resistant jackets and robust insulation materials that can withstand the corrosive effects of chemicals commonly found in industrial settings.

Mechanical Stress

Industrial environments can subject cables to mechanical stress, including vibration, bending, and crushing. Consider cables with high-tensile strength and flexibility to withstand these mechanical stresses. Additionally, armored cables can provide extra protection against physical damage.

Evaluating the transmission speed and bandwidth requirements

Your industrial application's transmission speed and bandwidth requirements will determine the type of Ethernet cables you need. Different types of wires have varying capabilities regarding data transmission speeds and bandwidth.

Cat 5e and Cat 6 Cables

Cat 5e and Cat 6 cables are suitable for most industrial applications that require high-speed and reliable connectivity. Cat 5e cables can support data transmission speeds of up to 1 Gbps, while Cat 6 cables can support speeds up to 10 Gbps. Consider Cat 6 cables if your application requires higher data rates.

Fiber Optic Cables

Fiber optic cables offer superior bandwidth capabilities and are ideal for applications that require long-distance data transmission. These cables can support data transmission speeds of up to 100 Gbps, making them suitable for high-bandwidth industrial applications.

Consider the Future

When evaluating the transmission speed and bandwidth requirements, it is essential to consider future scalability. Choose Ethernet cables supporting higher data rates than your current requirements to accommodate future growth and technological advancements.

Choosing the appropriate shielding for Industrial Ethernet Cables

Industrial environments often have electromagnetic interference (EMI) and radio frequency interference (RFI) sources. Selecting Ethernet cables with appropriate shielding is crucial to ensure reliable data transmission.

Unshielded Twisted Pair (UTP) Cables

UTP cables are the most common type of Ethernet cables used in industrial applications. They are cost-effective and suitable for environments with low levels of EMI and RFI. UTP cables rely on the twisting of pairs to reduce electromagnetic interference.

Foil Shielded Twisted Pair (F/UTP) Cables

F/UTP cables have an additional layer of foil shielding around the twisted pairs, providing better protection against EMI and RFI. These cables are suitable for environments with moderate levels of interference.

Overall Shielded Twisted Pair (S/FTP) Cables

S/FTP cables have individual foil shielding for each twisted pair and an overall braided shield. This design offers superior protection against EMI and RFI and is ideal for environments with high interference levels.

Selecting the suitable connector types for Industrial Ethernet Cables

Choosing the right connector types for industrial Ethernet cables is crucial for ensuring proper connectivity and compatibility with your network infrastructure. Several connector types are available, each with its advantages and applications.

RJ45 Connectors

RJ45 Connectors

RJ45 connectors are the most common type of connectors used in Ethernet networks. They are widely compatible and can be used with Cat 5e and Cat 6 cables. RJ45 connectors are relatively easy to install and provide a secure connection.

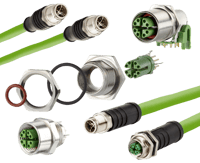

M12 Connectors

M12 Connectors

M12 connectors are commonly used in industrial applications due to their robustness and resistance to moisture and vibration. These connectors are available in different coding types, ensuring proper device mating.

LC and SC Connectors

LC and SC Connectors

LC and SC connectors are used with fiber optic cables. They provide a reliable and low-loss connection for high-speed data transmission over long distances. LC connectors are smaller, making them suitable for applications with limited space.

Considering the installation and maintenance requirements

When selecting industrial Ethernet cables, it is essential to consider the installation and maintenance requirements to ensure a smooth deployment and minimize downtime.

Ease of Installation

Consider the ease of installation and termination of the selected cables. Some cables may require specialized tools and expertise for installation, while others may have plug-and-play capabilities. Choose cables that align with your installation capabilities and requirements.

Cable Length

Determine the required cable length for your industrial application. Consider the distance between devices and the layout of your network infrastructure. It is recommended to add some extra length for flexibility and future modifications.

Maintenance and Serviceability

Evaluate the maintenance requirements of the selected cables. Some cables may require periodic inspections and cleaning to ensure optimal performance. Consider the availability of spare cables and connectors for quick replacements in case of failures.

Common Challenges and troubleshooting tips for Industrial Ethernet Cables

Even with careful selection and installation, industrial Ethernet cables can face challenges that may impact their performance. Here are some common challenges and troubleshooting tips to help you address these issues effectively.

Signal Degradation and Loss

Signal degradation and loss can occur due to cable length, improper termination, or excessive EMI/RFI. Ensure cables are correctly installed and terminated, and minimize the distance between devices when possible. Shielded cables can also help mitigate the impact of external interference.

Network Downtime

Cable failures, connector issues, or network configuration problems can cause network downtime. Regular inspections, testing, and preventive maintenance can help identify potential issues before they lead to downtime. Have spare cables, connectors, and network devices to quickly replace faulty components.

Cable Damage

Industrial environments can subject cables to physical damage, such as crushing or cutting. Ensure cables are adequately protected, especially in areas with heavy machinery or foot traffic. Consider using cables with armored jackets or implementing cable management systems to minimize the risk of damage.

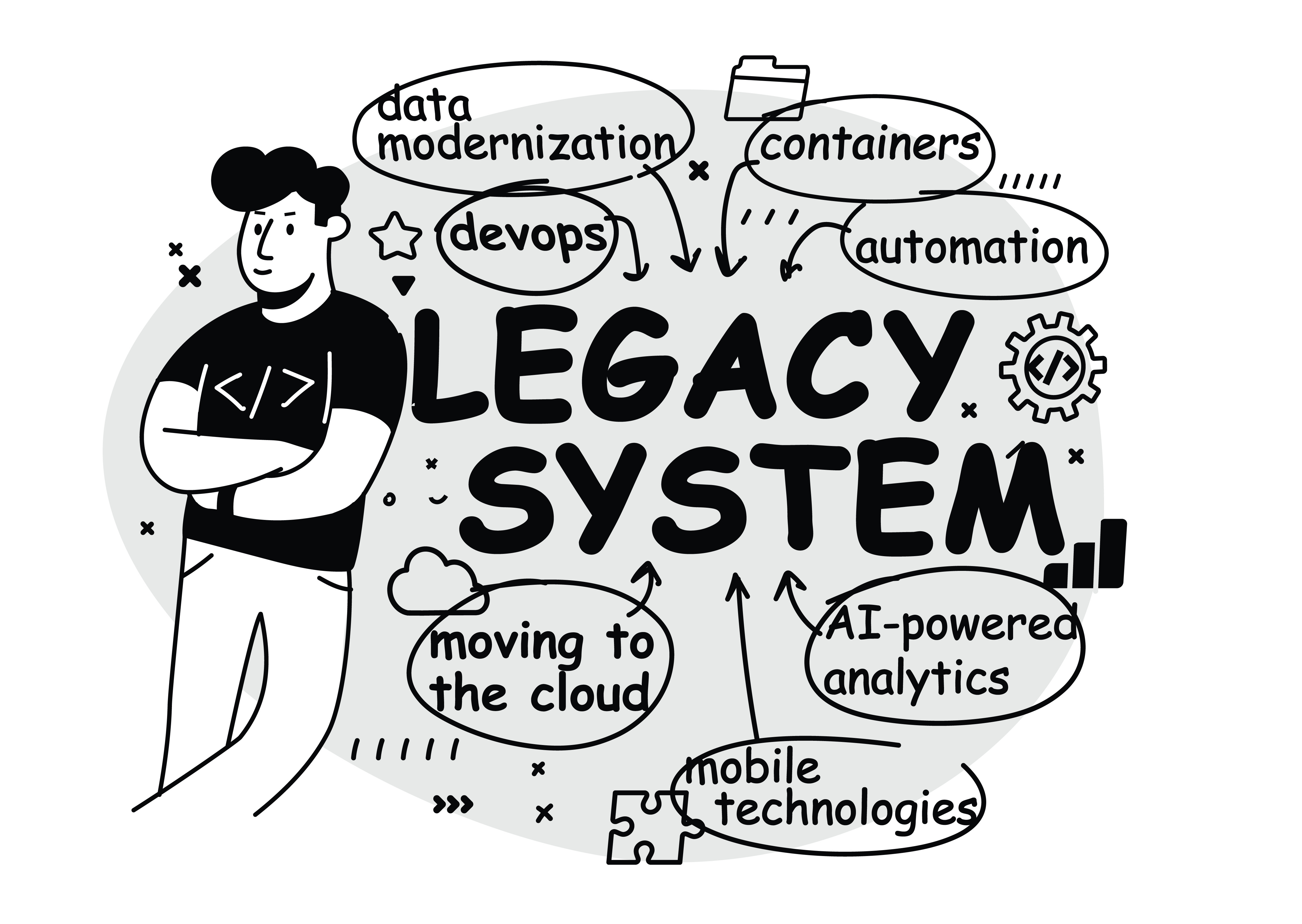

Conclusion: Making an informed decision for uninterrupted connectivity

Selecting the right Ethernet cables ensures uninterrupted connectivity and optimal performance in industrial environments. By understanding the different types of cables, assessing environmental requirements, evaluating transmission speed and bandwidth requirements, choosing appropriate shielding and connector types, and considering installation and maintenance requirements, businesses can make informed decisions and avoid costly disruptions.

Regularly inspect and maintain your Ethernet cables to ensure their long-term reliability. Invest in high-quality cables designed to withstand the harsh conditions of industrial environments. You should also invest in cable protection infrastructure, such as cable tray systems, to ensure the long cable life. These tips can make your network well-equipped for uninterrupted connectivity.

For more information on industrial Ethernet cables and how they can benefit your business, contact our team of experts today.