Solid State Relays (SSRs) have revolutionized the field of electrical switching, providing numerous advantages over traditional electromechanical relays. These electronic devices have gained popularity in various industries due to their enhanced performance, reliability, and longevity. In this comprehensive guide, you will gain a deep understanding of SSRs, their advantages, working principles, and the key factors to consider when upgrading to these advanced relays.

Advantages of Solid State Relays over Electromechanical Relays

Advantages of Solid State Relays over Electromechanical Relays

- Enhanced Reliability and Durability: Solid State Relays eliminate the need for mechanical components, such as contacts and coils, which are prone to wear and tear. Making SSRs highly reliable and durable, ensuring extended operational life compared to electromechanical relays.

- Fast Switching Speed: SSRs offer rapid switching times, allowing for precise control and response in various applications. This capability is particularly beneficial in industries where quick and accurate switching is essential, such as in industrial automation, HVAC systems, and semiconductor manufacturing.

- Noise-Free Operation: Unlike electromechanical relays that produce audible clicks and electrical noise during operation, SSRs offer silent switching. This characteristic is crucial in applications concerning noise pollution, such as audio equipment, medical devices, and laboratory instruments.

- Compact and Lightweight Design: Solid State Relays are compact and lightweight, making them suitable for space-constrained environments. Their smaller form factor enables efficient installation and facilitates the integration of multiple relays in a single system.

- Improved Safety: SSRs eliminate the risk of electrical arcing and sparking that can occur with electromechanical relays. SSRs are a safer choice in applications where preventing fires, explosions, or hazardous electrical events is paramount, such as in oil refineries, chemical plants, and aerospace systems.

Understanding the Working Principle of Solid State Relays

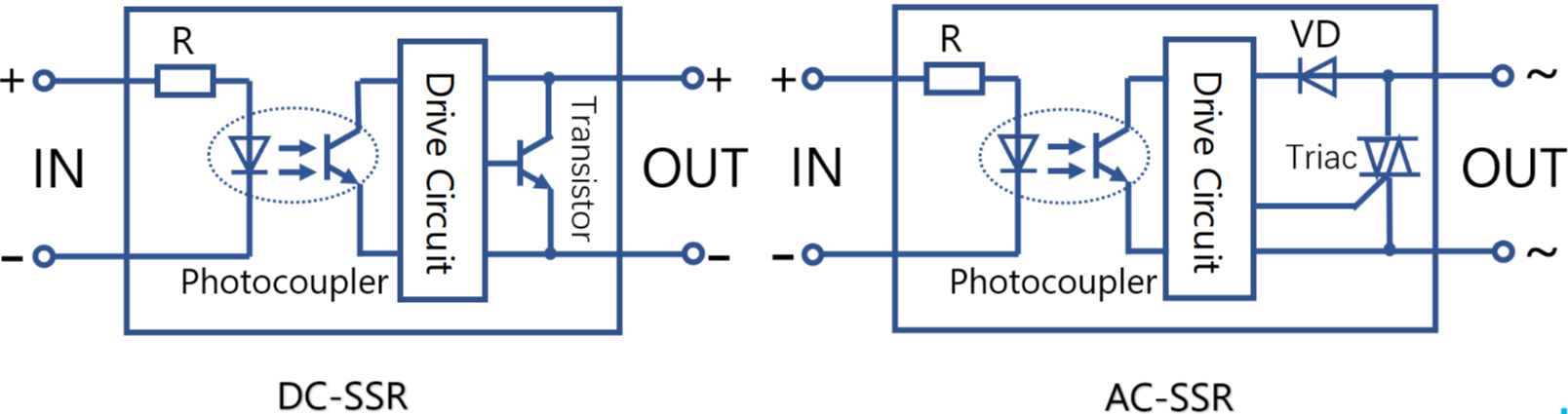

Solid State Relays operate based on the principle of opto-isolation. These devices consist of an input section and an output section that are electrically isolated. The input section typically comprises an LED (Light Emitting Diode) and a photo-sensitive component, while the output section consists of a power semiconductor device, such as a Triac or an SCR (Silicon Controlled Rectifier).

When a control signal is applied to the input section, the LED emits light, which activates the photo-sensitive component. This, in turn, triggers the power semiconductor device in the output section, allowing current to flow through the load connected to the relay. The absence of physical contacts in SSRs eliminates the wear and tear associated with electromechanical relays, ensuring a longer lifespan and more reliable operation.

Key Factors to Consider When Upgrading to Solid State Relays

Several key factors should be considered before upgrading to Solid State Relays to ensure a successful transition. These factors include:

- Load Compatibility: Solid State Relays have specific load compatibility requirements, including voltage and current ratings. It is crucial to assess whether the SSRs can handle the electrical load of your application. The load's inrush current and surge voltage characteristics should also be considered to avoid compatibility issues.

- Ambient Conditions: The operating environment of the SSRs plays a significant role in their performance and longevity. Factors such as temperature, humidity, and vibration levels should be evaluated to ensure that the chosen SSRs can withstand the conditions of your application. Some SSRs are designed for harsh environments with features like conformal coating or IP (Ingress Protection) ratings to enhance durability.

- Control Signal Compatibility: SSRs can be driven by various control signals, such as DC voltage, AC voltage, and even digital signals. It is essential to verify whether the control signal of your existing system is compatible with the input requirements of the SSRs. If not, additional signal conditioning circuitry may be required to ensure proper operation.

By carefully considering these key factors, you can select the most suitable Solid State Relays for your application, ensuring a smooth and efficient upgrade.

Signs that Indicate the Need for Upgrading to Solid State Relays

While electromechanical relays have been widely used for decades, several signs indicate the need for upgrading to Solid State Relays:

- Frequent Relay Failures: If you are experiencing frequent failures or malfunctions of electromechanical relays in your system, it may be a sign that the relays cannot handle your application's demands. Solid State Relays offer improved reliability and can withstand harsh operating conditions, reducing the likelihood of failures.

- Noise and Electrical Interference: If your system is sensitive to electrical noise or experiencing interference issues due to the switching of electromechanical relays, it is advisable to upgrade to Solid State Relays. SSRs provide noise-free operation, eliminating the risk of interference with sensitive equipment or signal integrity.

- Slow Switching Speed: In applications where quick response times are crucial, such as in motor control or process automation, electromechanical relays may not be able to provide the required switching speed. Solid State Relays offer fast switching times, ensuring precise control and optimal system performance.

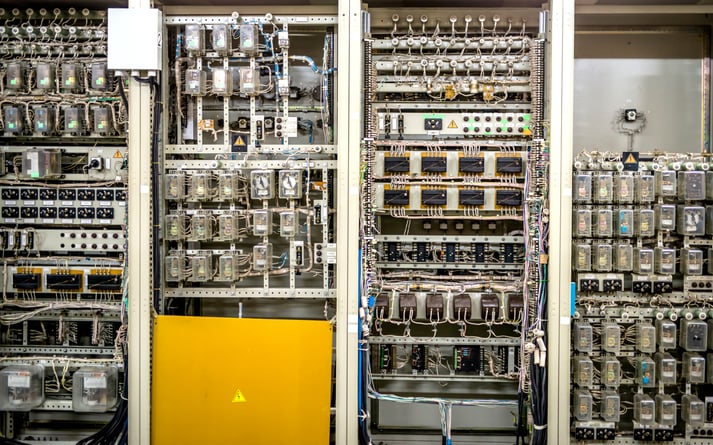

- High Maintenance and Replacement Costs: The maintenance and replacement costs associated with electromechanical relays can add up over time, especially in systems with an increased number of relays. On the other hand, Solid State Relays have a longer lifespan and require minimal maintenance, resulting in cost savings in the long run.

If you are experiencing any of these signs, it may be the right time to upgrade to Solid State Relays. The advantages of SSRs, such as enhanced reliability, noise-free operation, and fast switching speed, can significantly improve the performance and efficiency of your system.

Common Applications and Industries that Benefit from Solid State Relays

Solid State Relays find applications in various industries and offer benefits across a wide range of applications. Some of the typical applications and industries that benefit from Solid State Relays include:

- Industrial Automation: Solid State Relays are widely used in industrial automation systems for controlling motors, solenoids, and heaters. Their rapid switching speed, noise-free operation, and compact design make them ideal for precise and efficient control of industrial processes.

- HVAC Systems: Heating, Ventilation, and Air Conditioning (HVAC) systems require reliable and accurate control of heating elements, fans, and compressors. Solid State Relays offer excellent temperature control, fast response times, and high reliability, ensuring optimal performance and energy efficiency in HVAC applications.

- Medical Equipment: In medical equipment, such as MRI machines, incubators, and diagnostic devices, precise control and noise-free operation are critical. Solid State Relays offer silent switching and fast response times, making them suitable for medical applications where patient comfort and accurate measurements are essential.

- Renewable Energy Systems: Solid State Relays are commonly used in renewable energy systems, such as solar inverters and wind turbines, for efficient power conversion and control. Their high reliability, fast switching speed, and compatibility with DC and AC power sources make them an ideal choice for renewable energy applications.

- Food and Beverage Industry: The food and beverage industry often requires accurate and reliable control of temperature, mixing, and filling processes. Solid State Relays offer precise temperature control, fast response times, and immunity to electrical noise, ensuring high-quality production and adherence to food safety standards.

These are just a few examples of the many applications and industries where Solid State Relays provide significant benefits. The versatility and performance of SSRs make them a preferred choice in various fields, contributing to improved efficiency, reduced downtime, and enhanced safety.

How to Choose the Right Solid State Relays for Your Application

Choosing the right Solid State Relays for your application involves considering several factors to ensure compatibility and optimal performance. Here are some essential guidelines to help you make an informed decision:

- Load Voltage and Current Ratings: Determine your load's voltage and current requirements and select SSRs that can handle these values. Choosing SSRs with appropriate ratings is crucial to avoid overloading or underutilization, which can lead to performance issues or premature failure.

- Control Signal Compatibility: Verify whether your control signals are compatible with the input requirements of the SSRs. Consider the control signal type (DC or AC voltage) and the voltage level to ensure proper operation. Use signal conditioning devices or converters to match the control signals with the SSRs if necessary.

- Heat Dissipation and Thermal Management: Solid State Relays generate heat during operation, and proper heat dissipation is essential to prevent overheating and ensure reliable performance. Evaluate the thermal characteristics of the SSRs, such as their maximum operating temperature and thermal resistance, and design an adequate cooling system if required.

- Protection Features: Some SSRs come with built-in protection features, such as short-circuit protection, overvoltage protection, and overcurrent protection. Consider the specific needs of your application and choose SSRs that provide the necessary protection to safeguard your system and equipment.

- Supplier Reliability and Support: Select reputable suppliers or manufacturers who offer reliable products and excellent customer support. Check for certifications, warranties, and technical documentation to ensure you deal with trustworthy sources. A supplier's competency and experience will help you address any concerns or issues that may arise during the selection, installation, or operation of the SSRs.

By carefully considering these factors and evaluating the specific requirements of your application, you can choose the right Solid State Relays that will meet your needs and deliver optimal performance.

Installation and Maintenance Tips for Solid State Relays

Proper installation and maintenance ensure Solid State Relays' optimal performance and longevity. Here are some essential tips to keep in mind:

- Mounting: Follow the manufacturer's guidelines for mounting the SSRs. Ensure proper heat sinking or use thermal pads to facilitate heat dissipation. Avoid mounting the SSRs in areas with excessive vibration or near heat sources that can affect their performance.

- Electrical Connections: Make secure and properly sized electrical connections to minimize voltage drops and ensure efficient power transfer. Use appropriate wire gauges, terminal blocks, or connectors recommended by the SSR manufacturer to maintain reliable electrical connections.

- Protection Devices: Install protective devices, such as fuses or circuit breakers, to safeguard the SSRs and the load from excessive current, short circuits, or other electrical faults. These devices will help prevent damage to the SSRs and ensure the safety of your system and equipment.

- Regular Inspection: Inspect the SSRs for any signs of damage, loose connections, or overheating. Check the wiring and terminals for tightness and signs of wear. Replace any damaged or faulty SSRs immediately to prevent potential failures or accidents.

- Environmental Considerations: Ensure that the operating environment of the SSRs is within the specified temperature and humidity ranges. Provide proper ventilation or cooling to maintain the desired operating conditions if necessary. Protect the SSRs from dust, moisture, or other contaminants affecting their performance.

By following these installation and maintenance tips, you can maximize the reliability and lifespan of your Solid State Relays, ensuring trouble-free operation and avoiding unnecessary downtime.

Cost Considerations and Return on Investment (ROI) of Upgrading to Solid State Relays

The initial cost of upgrading to Solid State Relays may seem higher than electromechanical relays. However, it is essential to consider the long-term cost benefits and return on investment (ROI) that SSRs can offer. Here are some cost-related considerations to keep in mind:

- Maintenance and Replacement Costs: Solid State Relays have a longer lifespan and require minimal maintenance compared to electromechanical relays. A longer operating life reduces relays' maintenance and replacement costs, resulting in significant cost savings over time.

- Energy Efficiency: Solid State Relays offer high energy efficiency, minimizing power losses and reducing energy consumption. You can achieve substantial energy cost savings, especially in applications where relays are constantly switching or controlling high-power loads.

- Downtime and Productivity Losses: Solid State Relays' improved reliability and durability help minimize downtime due to relay failures or malfunctions. This translates into increased productivity and reduced losses associated with system downtime, ensuring a higher return on investment.

- Safety and Regulatory Compliance: Upgrading to Solid State Relays can help ensure compliance with safety regulations and standards, avoiding potential penalties or legal issues. SSR's will increase the overall cost-effectiveness and peace of mind in operating your system.

Total Cost of Ownership - When considering the cost of upgrading to Solid State Relays, evaluating the long-term benefits and potential savings these advanced relays can provide is crucial. A thorough cost analysis, considering maintenance costs, energy efficiency, downtime reduction, and safety compliance, will help you determine the true return on investment of upgrading to SSRs.

Comparison of Solid State Relays with Other Relay Options

Solid State Relays offer numerous advantages over traditional electromechanical relays. However, it is essential to consider the specific requirements of your application and compare SSRs with other relay options to make an informed decision. Here is a comparison of Solid State Relays with two common alternatives:

- Electromechanical Relays: Solid State Relays offer faster switching speeds, noise-free operation, and enhanced reliability compared to electromechanical relays. They are also more compact and lightweight, making them suitable for space-constrained applications. However, electromechanical relays may be more cost-effective for low-power applications or when precise control is optional.

- Reed Relays: Reed relays comprise a pair of magnetic contacts enclosed in a glass or ceramic envelope. While they offer fast switching speeds and excellent electrical isolation, reed relays are generally limited in current and voltage ratings compared to Solid State Relays. Additionally, the contacts in reed relays can wear out over time, leading to decreased reliability.

By comparing Solid State Relays' features, performance characteristics, and cost considerations with other relay options, you can determine your application's most suitable choice.

Conclusion and Final Thoughts

Solid State Relays (SSRs) provide numerous advantages over electromechanical relays, making them a compelling choice for various applications and industries. Their reliability, fast switching speeds, and compact design contribute to improved performance, energy efficiency, and system longevity.

Knowing when to upgrade to solid state relays depends on several factors, including the specific requirements of your application, signs of relay failure, and the need for faster switching speeds or superior protection. By carefully considering these factors and choosing the right SSRs for your application, you can enhance the performance and reliability of your system.

Remember to evaluate the cost considerations and potential return on investment (ROI) of upgrading to solid state relays. While the initial cost may be higher, the long-term benefits in terms of reduced maintenance, increased efficiency, and energy savings can make the investment worthwhile.

In conclusion, upgrading to solid state relays can improve system performance, enhance reliability, and costs savings. By understanding the advantages, working principles, and critical factors, you can decide on the right time to upgrade to solid state relays. Upgrade to SSRs and take your system to the next level of efficiency and reliability.

Check out our SSRs for your project

Ready to upgrade to Solid State Relays (SSRs)? Contact us today for expert advice and high-quality SSRs that meet your application's requirements.