In today's fast-paced industrial landscape, where connectivity is vital, Industrial Ethernet Connectivity has emerged as a reliable and robust solution. As digital transformation revolutionizes industries, the need for seamless communication and data exchange in harsh environments has become paramount. This blog delves into the world of Industrial Ethernet Connectivity, exploring its importance, challenges, solutions, and best practices for implementation.

Understanding Harsh Environments in Industrial Settings

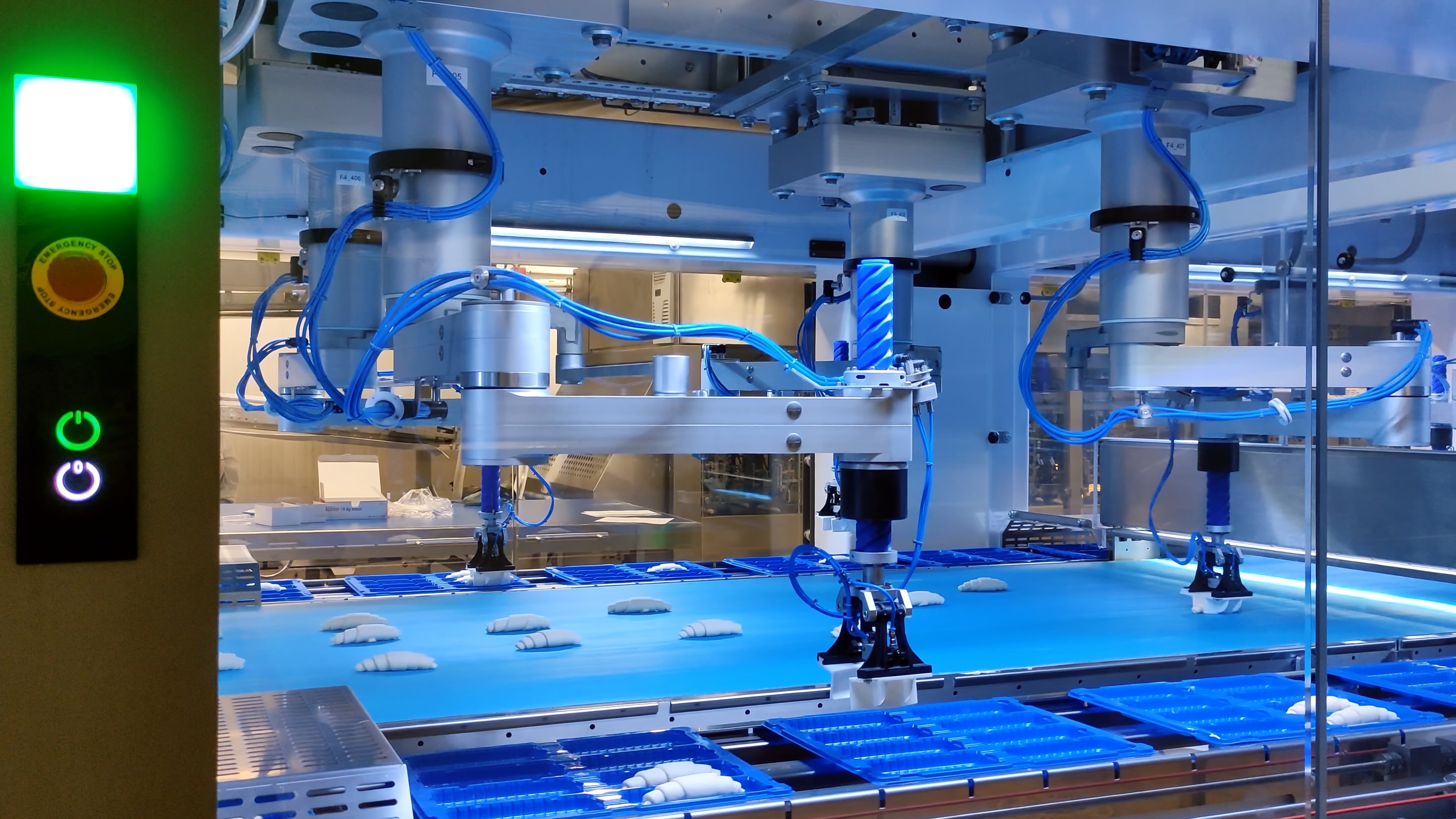

Industrial environments are notoriously harsh, characterized by extreme temperatures, high dust levels, humidity, and vibrations. These conditions pose significant challenges to traditional connectivity solutions, often resulting in data loss, network downtime, and compromised productivity. Industrial Ethernet Connectivity addresses these challenges by providing a rugged and resilient network infrastructure capable of withstanding these harsh conditions.

To truly navigate the complexities of harsh industrial environments, it is crucial to understand the unique factors that contribute to their harshness. Extreme temperatures, for instance, can cause equipment failure and signal degradation. The presence of dust and humidity can lead to corrosion and short circuits. Vibrations, common in industrial settings, can disrupt cable connections and compromise the integrity of the network. By comprehensively understanding these harsh environmental factors, organizations can effectively design and implement Industrial Ethernet Connectivity solutions that can thrive in such conditions.

Importance of Reliable Connectivity in Harsh Environments

Reliable connectivity is the backbone of any industrial operation, enabling real-time communication, data exchange, and control. In harsh environments, where traditional connectivity solutions fall short, Industrial Ethernet Connectivity emerges as a game-changer. It provides a robust and secure network infrastructure that ensures uninterrupted data transmission, even in extreme conditions.

Reliable connectivity is crucial in industries such as oil and gas, manufacturing, and mining, where downtime can result in significant financial losses. A momentary network disruption can lead to production delays, equipment damage, and compromised safety. Industrial Ethernet Connectivity eliminates these concerns by offering a stable, high-performance network that can withstand the harshest environments.

Challenges and Solutions for Industrial Ethernet Connectivity

While Industrial Ethernet Connectivity offers numerous benefits, it has its challenges. The harsh environments in industrial settings present obstacles that must be overcome for successful implementation. Some of the common challenges include temperature extremes, electromagnetic interference, and physical damage to cables and connectors.

To tackle these challenges, organizations can employ various solutions. Temperature-resistant Ethernet cables and connectors can withstand extreme temperatures, ensuring reliable connectivity in harsh environments. Shielded cables and connectors protect against electromagnetic interference, safeguarding data integrity. Additionally, implementing cable management systems and employing ruggedized Ethernet switches can minimize physical damage to cables and connectors.

Enhancing Strategies for Industrial Ethernet Connectivity

Organizations must enhance their strategies to fully unlock the potential of Industrial Ethernet Connectivity in harsh environments. This involves a comprehensive approach encompassing network design, equipment selection, and ongoing maintenance.

Firstly, organizations should prioritize network redundancy, implementing backup systems and redundant cabling to ensure uninterrupted connectivity. Redundancy minimizes downtime and provides a fail-safe mechanism in the event of equipment failure.

Secondly, the selection of reliable and ruggedized equipment is crucial. Industrial-grade Ethernet switches, routers, and connectors explicitly designed for harsh environments can withstand extreme conditions, ensuring the longevity and reliability of the network infrastructure.

Lastly, ongoing maintenance and monitoring are essential for the optimal performance of Industrial Ethernet Connectivity. Regular inspections, testing, and firmware updates can identify and address potential issues before they escalate, minimizing network downtime and maximizing productivity.

Best Practices for Implementing Industrial Ethernet Connectivity in Harsh Environments

Implementing Industrial Ethernet Connectivity in harsh environments requires careful planning and adherence to best practices. Here are some key considerations to ensure a successful implementation:

- Conduct a thorough site survey to identify environmental factors and determine the best locations for equipment placement.

- Use industry-certified Ethernet cables and connectors that are specifically designed for harsh environments.

- Implement proper grounding and shielding techniques to minimize electromagnetic interference.

- Employ cable management systems to protect cables from physical damage and ensure proper routing.

- Implement redundant network architecture to ensure uninterrupted connectivity and minimize downtime.

- Regularly monitor and maintain the network infrastructure, performing inspections, testing, and firmware updates.

By following these best practices, organizations can overcome the challenges of harsh environments and realize the full potential of Industrial Ethernet Connectivity.

Future Trends in Industrial Ethernet Connectivity

As technology continues to evolve, so does Industrial Ethernet Connectivity. Several trends are shaping the future of connectivity in harsh industrial environments:

- Wireless Connectivity: The emergence of wireless technologies such as Wi-Fi 6 and 5G is expanding the possibilities for Industrial Ethernet Connectivity. Wireless networks provide flexibility, mobility, and scalability, making them ideal for harsh environments where wired connections may be impractical.

- Edge Computing: The rise of edge computing is revolutionizing industrial connectivity by bringing computing power closer to the data source. This reduces latency, enhances security, and improves real-time decision-making capabilities, making it an attractive solution for harsh environments.

- Cybersecurity: With the increasing connectivity and digitalization of industrial environments, cybersecurity is a growing concern. Future Industrial Ethernet Connectivity solutions will prioritize robust security measures to protect critical infrastructure from cyber threats.

- Artificial Intelligence: AI-powered analytics and predictive maintenance are transforming industrial operations. Industrial Ethernet Connectivity will be crucial for enabling the seamless data transmission required for AI applications, enhancing efficiency, and optimizing productivity.

Industrial Ethernet Connectivity Products and Solutions

Organizations can turn to a wide range of products and solutions to fully unlock the potential of Industrial Ethernet Connectivity in harsh environments. These include ruggedized Ethernet switches, industrial-grade cables and connectors, temperature-resistant equipment, and network management software. By leveraging these products and solutions, organizations can build a resilient and reliable network infrastructure that can thrive in even the harshest environments. Some of the products with solutions are discussed below:

Industrial Ethernet Switches:

Remote IO:

Industrial Edge Controller:

Connectors:

Network Cabling:

Conclusion: Unlocking the Potential of Industrial Ethernet Connectivity in Harsh Environments

In conclusion, Industrial Ethernet Connectivity is revolutionizing how industries navigate harsh environments. Its robustness, reliability, and resilience provide a game-changing solution for seamless communication and data exchange. Organizations can unlock the full potential of Industrial Ethernet Connectivity in harsh industrial settings by understanding the unique challenges, implementing best practices, and leveraging innovative solutions. Embracing this technology will pave the way for increased efficiency, productivity, and safety, ensuring a competitive edge in today's digital age.

Explore the possibilities of Industrial Ethernet Connectivity in your industry today and unlock the potential of seamless communication and data exchange in even the harshest of environments. Contact us today to learn more.