Taking Production to the Next Level

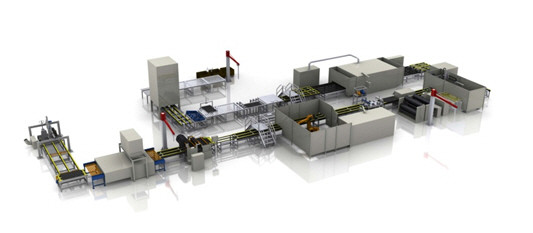

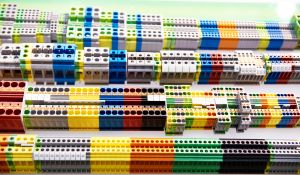

Over the past few decades, market trends have shown that automation, whether we like it or not, is where the majority of industries are heading. While there has been a level of automation present in the industrial sector for quite a while now, the advent of the internet and the interconnectivity that it allows for has boosted automation to the next level. With machines becoming smarter and designed to be better at communicating with other machines on the factory floor, automation is poised to change the way that factories operate in a much shorter timespan than most people realize. Here at Dynamic Measurement & Control Solutions, LCC, we help industries automate their processes by providing them with automation components that allow them to connect their equipment to modern control systems, monitor environmental conditions in real-time at production facilities, and convert between proprietary and open device protocols. In today’s post, we are going to cover why automation has become so important and why more and more industries are trusting their daily processes to robots. Continue reading to learn more.

Increase Efficiency With Industrial Automation

For any industry, efficiency is an important metric to keep track of. It doesn’t matter if a factory is able to produce the best product in their vertical if they cannot do so in a way that makes the most out of the time, money, and energy that is put into each product. Producing high-quality items in an efficient manner is the best way for an industry to find success and, below, we have listed some of the ways that automation helps industries accomplish this task.

- Consistent Production: An important aspect of any factory is to be able to produce products that are consistent in nature. For example, if you run a factory that specializes in producing metal bowls, the first bowl off of the production line should be as close to identical as the last bowl off of the production line at the end of the day. While the quality of machines used in a factory affects the end product, human error can lead to products falling out of consistency standards. Automation helps make sure that products are produced using the exact same method every single time, helping to reduce issues associated with quality control.

- Increased Productivity: Another important variable in relation to efficiency is the speed at which a factory can produce a product. Again, it doesn’t matter if a factory is able to produce the best product in the world if they can’t do so in an efficient amount of time. With automation in place, factories are able to produce items on a consistent basis, theoretically making it possible to have a nearly non-stop production schedule. With the right automation systems in place, many industrial processes cross over into the realm of “set it and forget it” territory, reducing the amount of time and labor associated with the running and monitoring of machines.

- Decreased Labor Cost: Often considered the best (and worst) benefit to automation, decreased labor costs are one of the main metrics by which the viability of automation is measured. If a factory can reduce their workforce by 50 percent due to automation, that is 50 percent less money the industry has to pay out in salary and benefits for those workers. This is a benefit to the specific industry, however, time will tell whether or not automation is the best path to take in relation to workers.

- Increase Safety: When a machine functions under automated control, it is much less likely that a worker will find himself in a situation where they can become injured. This good for both the worker and the industry because it increases the safety of workers on factory floors while also reducing the amount of money that an industry has to pay out due to workplace injuries.

If you would like to learn more about the components that we offer for automation solutions, please visit our website today. Providing our clients with the best brands available, we are certain that we have the products you need to get the most out of your industrial processes and increase the efficiency of your business.