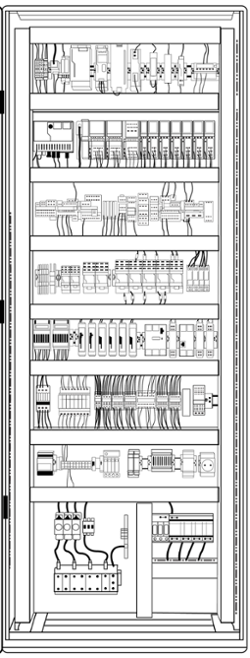

Control Panels

COMPLETE INDUSTRIAL CONTROL COMPONENT SOLUTIONS FOR YOUR SYSTEM

Control panels are found in “all” manufacturing process applications, but a few examples would be:

- Industrial Control Panels

- Process Control Systems

- Machine Control Systems

- Lighting Control Panels

- Electrical Control and Power Distribution

- Power Generation / Transmission / Distribution

- Alternative Energy Panels (Remote) Solar, Wind and Hydro Power

- Energy Storage Systems

- Motor Drive and VFD Control Panels

- Industrial Networking and Data Acquisition Panels

READ MORE ABOUT THE KEY COMPONENTS AND DESIGN GUIDELINES

Want to know the most important components and standards? Unsure of which products from our range are suitable for your industry?

Discover for yourself or give us a call!

Electrical systems and components run at a very high rate and are exposed to extreme conditions. Keeping your manufacturing process up and running or your machine "on" is of the utmost importance. Electrical systems require regular maintenance and attention so you need to be aware of how things work together. A lot of companies use electrical components that are not thoughtfully implemented or of low quality.

If you have questions about designing control panels, or industrial equipment or just want to know the most important industrial control components considerations before you start designing, please reach out. We have also prepared some guides that examine the most common control panel types, their roles in the manufacturing process, and the more important electrical components you should be thinking about while still in the design phase of your panel.