According to the Equipment Leasing and Finance Association, U.S. businesses are expected to invest more than 2 trillion dollars in equipment and software in 2024. More than half of all equipment acquisitions will be financed rather than purchased outright, a continuation of the long shift from capital expense to operating expense.

As interest rates begin to trend downward, machine builders and equipment manufacturers are preparing for a new cycle of investment. This environment favors companies that can offer flexible financing models and service-based programs. It also rewards the OEMs who design machines that provide more uptime, more data visibility, faster integration, and lower lifetime operating costs.

Equipment as a Service Is Accelerating

ELFA reports that Equipment as a Service is growing nearly 50 percent annually through 2030. Half of end users already use subscription or service-based models and another twenty three percent plan to adopt them in the next two years. For machine builders, this is redefining the value proposition.

EaaS favors equipment that is:

-

Reliable under continuous duty

-

Easy to service, monitor, and upgrade

-

Connected through industrial data pathways

-

Built on modular, replaceable hardware that lowers downtime risk

When your revenue depends on performance over time rather than a one-time sale, your hardware choices become strategic.

Automation, Robotics, and AI Investments Are Rising

The same ELFA trend report highlights that automation, robotics, and AI are among the strongest categories for upcoming investment, especially in logistics and manufacturing. These systems demand higher performance in power delivery, deterministic networking, remote I/O, thermal management, and serviceable wiring.

Machine builders who integrate the latest hardware platforms will position themselves to capture a larger share of these financed investments.

Why Better Hardware Matters in a Financed Future

When a buyer finances equipment, their evaluation criteria change. They look for:

-

Lower lifetime operating costs

-

Predictable maintenance schedules

-

Scalable control architecture

-

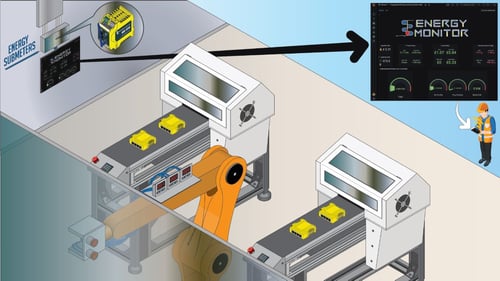

Remote monitoring and analytics

-

Safety, reliability, and compliance

This is where many OEMs gain or lose competitive ground. Finance-backed buyers will choose the machine with better power stability, smoother control performance, cleaner data paths, and easier field service.

That advantage starts in the design phase, not after the machine is shipped.

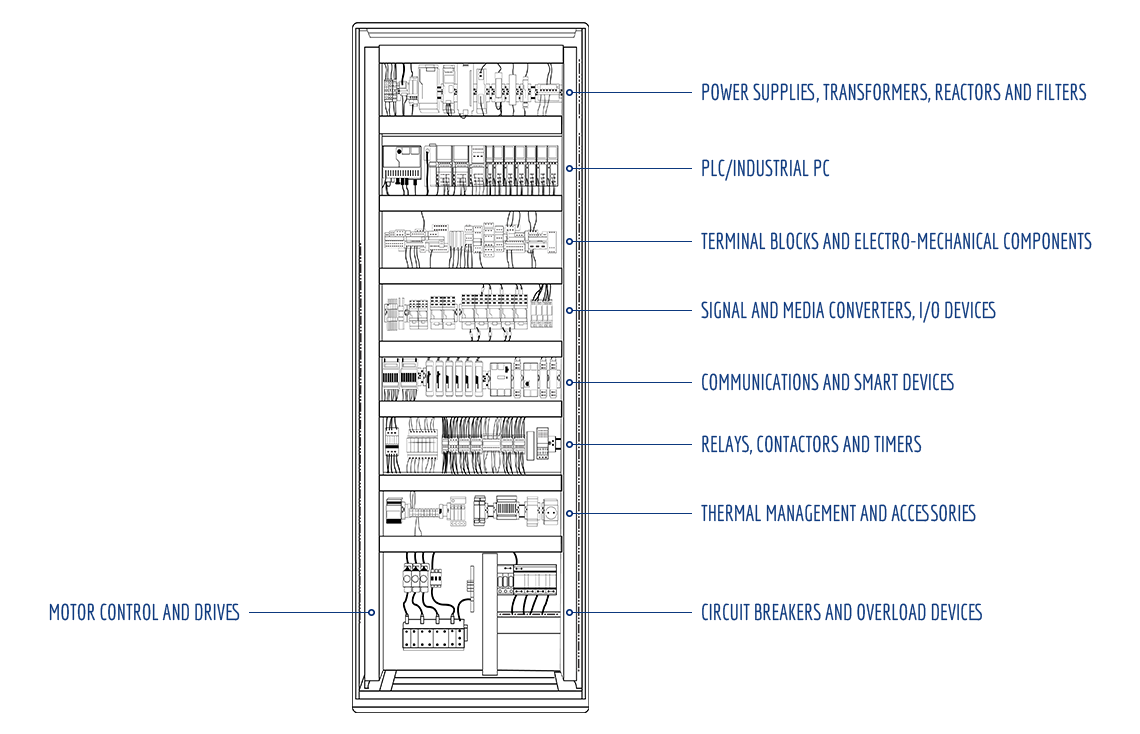

How Dynamic Supports OEMs in the Design Phase

Dynamic works with machine builders who want to position themselves ahead of these trends. We support engineering teams with hardware choices that improve reliability, performance, and serviceability for EaaS and financed equipment models.

Our work focuses on five areas that directly impact long-term system value:

-

Power That Performs

High-efficiency supplies, DC/DC converters, and stable power architectures for sensitive loads. -

Integrated Control Solutions

PLC, remote I/O, safety components, solid-state switching, and intelligent control elements. -

Industrial Data Pathways

Deterministic networking, edge devices, Ethernet I/O, and high-speed communication modules. -

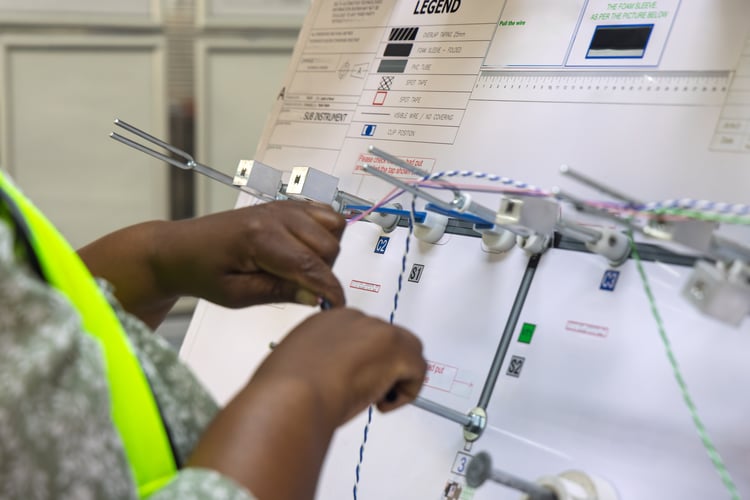

Wired to Last

Proper cable entry, routing, interconnect, vibration-resistant connectors, and field-replaceable wiring. -

Thermal Control and Enclosure Systems

Keeping electronics cool, clean, protected, and serviceable.

These areas directly support higher uptime, faster deployment, and better lifecycle economics. They allow OEMs to deliver machines that perform better in financed and subscription-based environments.

Position Your Machine for the Next Wave of Demand

As financing becomes the dominant path for equipment acquisition, the winners will be the machine builders who design systems that deliver lower lifetime cost, better connectivity, and higher reliability.

If your team is preparing new designs for the next cycle of investment, Dynamic can support you with the right power, control, and data hardware to keep you ahead of the market.