Winemaking requires precision, but behind the scenes, your winery’s electrical infrastructure is crucial in ensuring smooth operations. Wet environments, high seasonal power demands, and voltage compatibility issues create risks that can lead to downtime, unsafe conditions, or costly equipment failures.

At Dynamic Measurement and Control Solutions, we understand the unique power challenges of wineries. As a trusted manufacturer’s rep, we recommend Walther Electric’s rugged, high-performance electrical solutions—including pin and sleeve connectors, motor disconnects, interlock switches, and power distribution systems—designed to ensure safety, reliability, and efficiency in both wet and dry processing areas.

Let’s look closer at the common electrical pain points in wineries and how we can help solve them …..

Challenge #1: Water Exposure Creates Electrical Safety Hazards

The Problem

From fermentation tanks to barrel cleaning stations, wineries deal with constant exposure to water and humidity. Improperly sealed electrical connections in these areas can lead to:

- Short circuits and unexpected downtime

- Increased risk of electrical shock

- Costly damage to equipment and control systems

The Solution: Watertight Interlocked Disconnect Switches

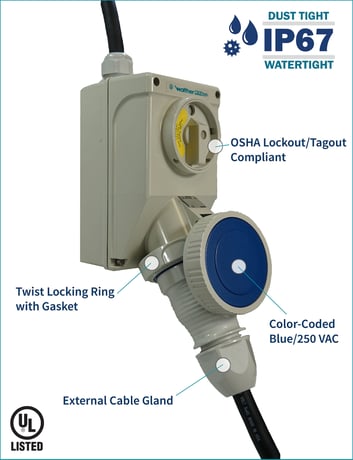

Walther Electric’s Motor Disconnect Switches are built to handle extreme moisture exposure and meet IP67 waterproof standards.

These disconnects:

✅ Prevent water intrusion with twist-lock housings that keep moisture out.

✅ Ensure OSHA-compliant Lockout/Tagout (LOTO) for safe maintenance.

✅ Withstand high-pressure washdowns in bottling and sanitation areas.

These durable motor disconnects allow wineries to reduce safety hazards and keep operations running without electrical failures.

Challenge #2: Voltage Mismatches Between Equipment Lead to Damage and Downtime

The Problem

Many wineries operate a mix of U.S. (208V) and European (480V) equipment. Incorrect voltage connections can:

- Burn out motors and control systems

- Cause unexpected equipment failures during peak production

- Create troubleshooting nightmares for facility managers

The Solution: Color-Coded Pin and Sleeve Connectors

Walther Electric’s Pin and Sleeve Connectors provide a simple and secure way to manage voltage compatibility:

✅ Color-coded design ensures quick, mistake-proof voltage matching.

✅ Industrial-grade, IP67-rated housings protect against dust, moisture, and accidental disconnects.

✅ Heavy-duty, twist-lock mechanisms provide uninterrupted power connections.

Facilities can prevent voltage mismatches and reduce costly downtime by standardizing winery power connections with these rugged components.

Challenge #3: Seasonal Power Demands Overload Winery Electrical Systems

The Problem

Harvest season dramatically increases the electrical load, with additional bottling lines, refrigeration units, and processing equipment in use.

Overloaded circuits and makeshift power setups can result in:

- Frequent tripped breakers and system shutdowns

- Inconsistent power supply causing production delays

- Fire risks from overtaxed electrical panels

The Solution: Scalable Power Distribution Units (PDU's)

Walther Electric’s Power Distribution Units (PDUs) are designed to handle peak power demands safely and efficiently:

✅ Portable, scalable units that expand winery power capacity without major electrical work.

✅ Clear voltage labeling (208V and 480V) for easy, safe connections.

✅ Built-in overcurrent protection prevents dangerous system overloads.

With proper PDUs in place, wineries can increase seasonal capacity without risking power failures or safety violations.

Challenge #4: High-Traffic Areas Create Cable Management Risks

The Problem

Winery floors are busy with forklifts, pallet jacks, and foot traffic. Loose or exposed cables can cause:

- Tripping hazards for workers

- Unreliable connections and intermittent power failures

- Increased wear and tear, leading to frequent replacements

The Solution: Heavy-Duty Cable Assemblies and Protectors

Walther Electric’s Industrial Cable Solutions help wineries organize and protect power infrastructure:

✅ Oil, heat, and moisture-resistant cable assemblies withstand demanding environments.

✅ Twist-lock power connectors prevent accidental disconnections.

✅ Custom-length options ensure a neat, hazard-free installation.

Paired with a cable bridge for protection, these solutions improve safety, enhance power reliability, and reduce long-term maintenance costs.

Challenge #5: Electrical Compliance and Safety Standards Must Be Met

The Problem

Wineries must comply with OSHA, NEC, and NFPA 70 electrical safety standards. Failing inspections or operating with non-compliant systems can result in:

- Hefty fines or shutdowns

- Increased insurance liabilities

- Risk of electrical fires or workplace injuries

The Solution: Interlock Switches for Safe Equipment Use

Walther Electric’s Interlock Switches ensure power is only active when conditions are safe:

✅ Prevents accidental machine startups during maintenance.

✅ Locks power sources to protect workers during equipment servicing.

✅ Meets OSHA safety standards, reducing liability and compliance risks.

By implementing smart electrical controls like interlock switches, wineries can improve worker safety and ensure long-term regulatory compliance.

Partner with Dynamic for Safer Winery Electrical Systems

Electrical challenges in wineries aren’t just an inconvenience—they can slow production, damage equipment, and put workers at risk. But with the right solutions, these problems disappear.

At Dynamic Measurement and Control Solutions, we specialize in helping wineries:

🔹 Improve electrical safety in wet environments

🔹 Eliminate voltage mismatch risks

🔹 Expand seasonal power capacity with scalable PDUs

🔹 Ensure compliance with OSHA and NEC standards

We’ve partnered with Walther Electric to bring industry-leading power solutions to wineries that need dependability, safety, and long-term efficiency.

Is your winery ready for an electrical upgrade? Let’s talk.

📞 Contact Dynamic today to discuss your facility’s specific needs.