SENSORS AND TRANSDUCERS

PRODUCT HIGHLIGHTS

NON-CONACT INDUSTRIAL SENSORS

- Product Range: Sensors for detecting transparent objects, glass substrates, wafers, PCBs, water, and cars.

- Variety of Sensors: Photoelectric, Ultrasonic, Laser, and Fiber Optic sensors designed for industrial automation and OEM applications.

- Specialized Applications: Sensors are suitable for factory line automation, hot metal detection, and specific industry needs like steel and heavy industry.

- Technology Features: Offers background/foreground suppression, color and mark detection, and light curtain sensors.

- Specialty Applications: Semiconductor Laser Projectors and RGB Spectroscopy for advanced industrial and medical applications.

CAPACITIVE AND INDUCTIVE SENSORS

Capacitive and inductive sensors can be used to detect a variety of materials, including metal, plastic, and liquids.

-

Capacitive sensors are used to detect the presence or absence of an object by measuring changes in capacitance between the sensor and the object.

-

Inductive sensors are used to detect the presence or absence of an object by measuring changes in inductance between the sensor and the object.

-

Capacitive and inductive sensors are designed for use in a variety of environments, including harsh industrial environments with high temperatures and vibrations.

-

Capacitive and inductive sensors can be used in a variety of applications, including object detection, level sensing, and proximity sensing.

-

Capacitive and inductive sensors are often used in automation and manufacturing systems to improve process efficiency and reduce the risk of equipment damage.

-

Capacitive and inductive sensors can be integrated with other automation systems, such as PLCs or SCADA systems, to enable remote monitoring and control.

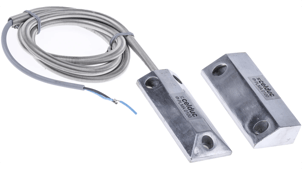

SAFETY MAGNETIC SENSORS

Safety magnetic sensors are used to detect the position of doors, guards, and other movable components in machinery and equipment.

-

Safety magnetic sensors work by detecting the presence of a magnet or magnetic field, typically mounted on the moving component, and sending a signal to a controller or safety system when the component is in the desired position.

-

Safety magnetic sensors are typically used in applications where it is critical to ensure that a moving component is in a safe position before equipment operation can continue.

-

Safety magnetic sensors are designed for use in harsh industrial environments and are often rated for IP67 or higher ingress protection.

-

Safety magnetic sensors can be integrated with other safety systems, such as emergency stop buttons and light curtains, to create a comprehensive safety solution.

-

Safety magnetic sensors can help reduce the risk of operator injury and equipment damage by preventing machinery from operating when guards or doors are not in the correct position.

-

Safety magnetic sensors are critical tools for engineers and operators in manufacturing and automation applications that require high levels of safety and reliability.

MAGNETIC PROXIMITY SENSORS

Magnetic proximity sensors are used to detect the presence or absence of a magnet or magnetic field.

-

Magnetic proximity sensors work by measuring changes in magnetic fields and sending a signal to a controller or automation system when a magnet or magnetic field is detected.

-

Magnetic proximity sensors can be used to detect a variety of materials, including ferrous and non-ferrous metals, as well as magnets.

-

Magnetic proximity sensors are non-contact sensors, meaning they do not physically touch the object being sensed.

-

Magnetic proximity sensors are designed for use in a variety of environments, including harsh industrial environments with high temperatures and vibrations.

-

Magnetic proximity sensors can be integrated with other automation systems, such as PLCs or SCADA systems, to enable remote monitoring and control.

MERCURY TILT SWITCHES

Mercury tilt switches are devices used to detect the tilt angle of a component or an object in a manufacturing or automation process.

-

The switch is made up of a sealed glass bulb containing a small amount of mercury and two or more electrical contacts.

-

When the bulb is tilted, the mercury flows to the lower side and connects the electrical contacts, completing a circuit.

-

Mercury tilt switches are commonly used in applications such as alarm systems, automotive safety devices, and industrial automation.

-

However, due to environmental concerns regarding the toxicity of mercury, the use of mercury tilt switches has been limited in recent years and alternative technologies such as solid-state and MEMS-based sensors have become more prevalent.

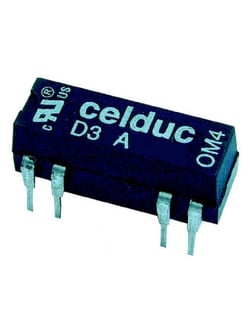

REED RELAYS & SWITCHES

Reed relays and switches are electromagnetic devices that use a thin, flexible metal strip called a reed to control the flow of current in a circuit.

-

When a magnetic field is applied, the reed bends and makes or breaks contact with a fixed electrical contact, allowing or stopping the flow of current.

-

Reed relays and switches are commonly used in applications such as telecommunications, automation, and security systems.

-

They offer advantages such as high switching speed, low power consumption, and excellent isolation between the control and switching circuits.

-

Reed relays and switches are available in various forms including surface-mount and through-hole packages, making them suitable for use in a wide range of applications.