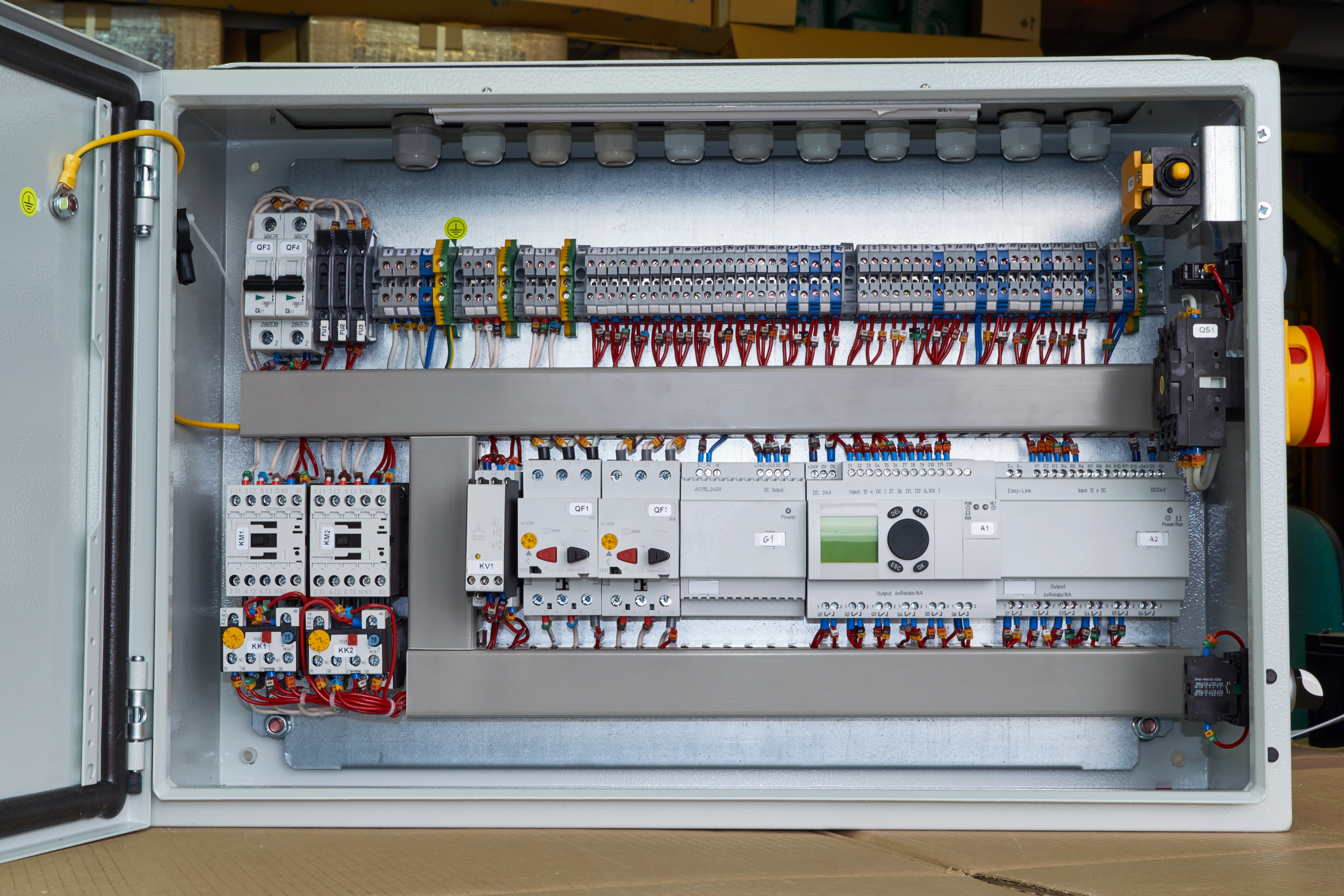

INDUSTRIAL CONTROL PANELS

Industrial control panels are systems used to regulate and manage electrical and mechanical operations in a variety of industrial and commercial applications. The panels are intended to monitor and regulate a variety of operations, including motor control, lighting control, temperature management, and process control. The components in the panels can be wired and programmed to execute specific duties, such as starting and stopping motors, regulating fluid flow, and monitoring process conditions. These panels are crucial to maintaining the safe and effective operation of several industrial and commercial equipment.

HIGHLIGHTS

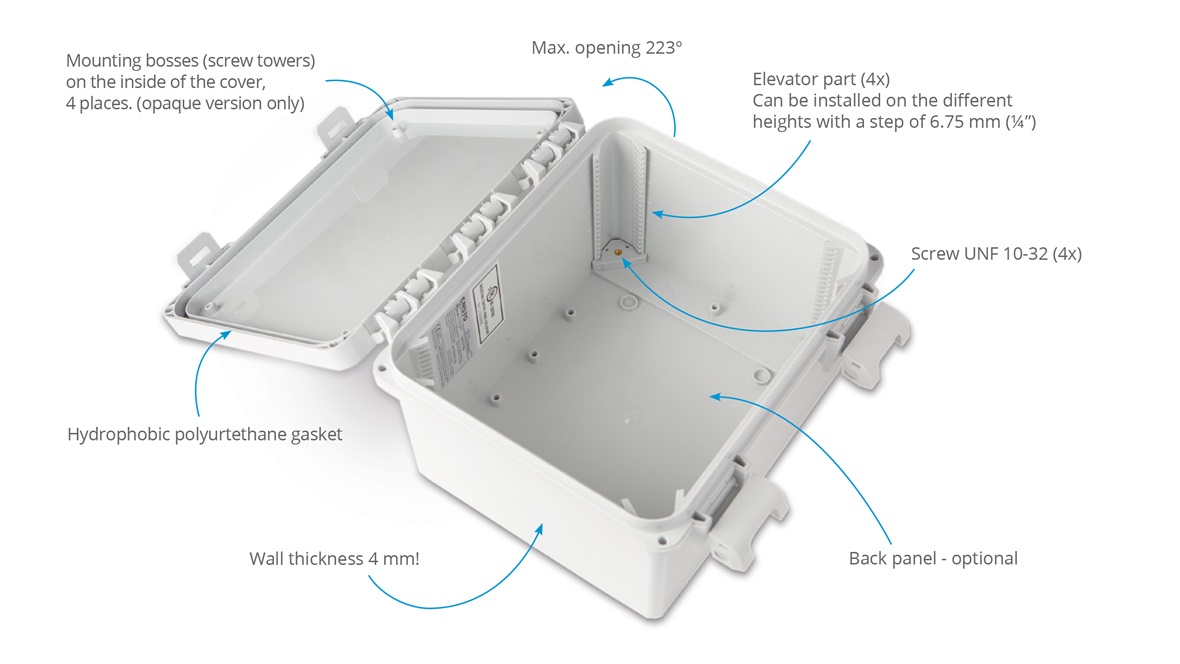

Made from lightweight yet durable materials like fiberglass, polycarbonate, and PVC, these enclosures offer excellent protection against harsh industrial environments, including dust, moisture, chemicals, and extreme temperatures. The Ensto Polybox has a very stylish and modern appearance as well as maintains a rugged look and feel, not like some other brands that feel "cheap and flimsy".

Available in standard JIC (Joint Industrial Council) sizes from 8x6x4 through 18x16x10

- Corrosion Resistant

- Light Weight

- Temperature Stable

- Cannot Become Electrically Conductive

- No Sharp Corners

- Easy to Modify (no special tools)

- Rugged and Long Life Span

- Overall Very Cost Effective

An HMI (Human Machine Interface) is an essential component of an industrial control panel that provides a graphical user interface for interacting with the underlying control systems. The primary purpose of an HMI is to display real-time process data and provide a means for operators to interact with the control system.

- Easy to Use

- Real-time Information

- Alarms and Notifications

- Data Logging and Reporting

- Communication with the Control Systems

- Customizable

- Secure

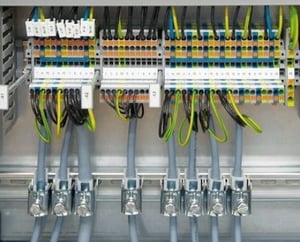

Cable entry frames are used in industrial control panels to provide a secure and organized means for cables to enter and exit. They help protect cables from damage and ensure wires are organized; they can also prevent unauthorized access to the control panel, where a cable gland just be unscrewed.

A tool-free, IP66, or IP54 sealed passage or insertion of assembled and unassembled cables and hoses are made possible by CONTA-CLIP's cable entry systems.

- Cable Protection

- Cable Organization

- Environmental Protection

- Easy to Install

- Cost Effective

-

With the ability to monitor and control production processes in real-time, businesses can quickly identify and resolve issues, minimizing downtime and maximizing productivity.

-

With Ethernet communications, businesses can create a reliable and efficient network infrastructure that supports real-time control and monitoring of production processes.

-

Businesses need to prioritize safety in their industrial processes to ensure the well-being of their employees and equipment.

-

Automation systems and control panel building technologies can help businesses reduce labor costs and increase production output by streamlining and automating routine tasks.

-

For systems that are less then 600V, considering a busbar systems can reduce panel size by 25%.

-

When considering TCO, it's crucial to consider maintenance costs, software and licensees, training, energy efficiency, downtime, and productivity factors.

HOW CAN WE HELP DESIGN YOUR NEXT SYSTEM?

- Control

- Communications

- Safety

- Labor

- Space

- TCO

Control

An electrical control system is a physical interconnection of devices that influences the behavior of other devices or systems. It comprises an input, a process, and an output. Input devices such as sensors gather and respond to information and control a physical process using electrical energy as an output action.

An electrical control system is a physical interconnection of devices that influences the behavior of other devices or systems. It comprises an input, a process, and an output. Input devices such as sensors gather and respond to information and control a physical process using electrical energy as an output action.

Control systems enable businesses to optimize production processes, reduce costs, and maintain consistent product quality by monitoring and regulating various industrial processes. Automation and electrical control panels allow manufacturers to streamline processes, reduce labor costs, and minimize the risk of human error. Control systems also enable companies to manage their production processes, ensure safety, and maximize productivity.

Communcations

Industrial networks and Ethernet communications enable seamless and fast data exchange between machines, devices, and components, allowing businesses to optimize production processes, reduce costs, and maintain consistent product quality.

Industrial networks and Ethernet communications enable seamless and fast data exchange between machines, devices, and components, allowing businesses to optimize production processes, reduce costs, and maintain consistent product quality.

Industrial networks and Ethernet communications enable seamless and fast data exchange between various machines, devices, and components, providing a foundation for a fully integrated and interconnected industrial ecosystem.

Safety

Safety systems are essential for ensuring the safety of employees and equipment in an industrial environment, such as emergency shutdown systems, interlock systems, fire suppression systems, and personnel protection systems. By integrating safety systems into industrial control systems, businesses can minimize the risk of accidents and protect their employees and customers from injury or harm.

Safety systems are essential for ensuring the safety of employees and equipment in an industrial environment, such as emergency shutdown systems, interlock systems, fire suppression systems, and personnel protection systems. By integrating safety systems into industrial control systems, businesses can minimize the risk of accidents and protect their employees and customers from injury or harm.

Safety is critical in an industrial setting that uses automation, electrical control panels, and industrial control components, ensuring the safety of employees, equipment, and anyone who may come into contact with them. The most important thing for a business is to minimize the risk of accidents and downtime.

Labor Savings

Automation systems and control panel building technologies can help businesses reduce labor costs and increase production output by streamlining and automating routine tasks. By utilizing automated equipment and robotics, companies can improve their production processes and reduce the need for manual labor. Reducing manual work can significantly save labor costs and improve overall efficiency. In addition, automation systems and industrial control component technology can help businesses minimize the risk of human error, ensuring consistent and reliable product quality.

Automation systems and control panel building technologies can help businesses reduce labor costs and increase production output by streamlining and automating routine tasks. By utilizing automated equipment and robotics, companies can improve their production processes and reduce the need for manual labor. Reducing manual work can significantly save labor costs and improve overall efficiency. In addition, automation systems and industrial control component technology can help businesses minimize the risk of human error, ensuring consistent and reliable product quality.

Companies must invest in the right technology and systems to effectively create savings, and partner with vendors to consult on new machines and processes. By doing so, businesses can benefit from increased efficiency, productivity, and profitability and maintain a competitive edge in their industry.

Space Savings

Saving space in an industrial control panel is essential to optimize available space and maximize efficiency. Using compact components such as miniature circuit breakers, slim relays, and smaller or multi-level terminal blocks can help save space in a control panel.

Saving space in an industrial control panel is essential to optimize available space and maximize efficiency. Using compact components such as miniature circuit breakers, slim relays, and smaller or multi-level terminal blocks can help save space in a control panel.

When designing you should use compact components, plan the layout, use modular designs, utilize vertical space, optimize wiring, and use color-coded wiring. These strategies can help businesses save space in their control panels and optimize available space, leading to improved efficiency, reduced costs, and increased productivity.

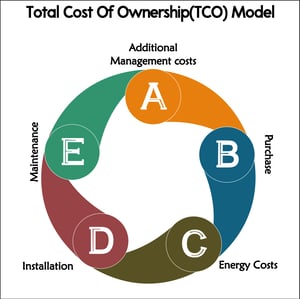

Total Cost of Ownership

When building or specifying industrial equipment for a manufacturing environment, it is important to consider the total cost of ownership (TCO). TCO considers not only the upfront cost of purchasing the equipment, but also the cost of operating and maintaining it over its lifespan. This includes maintenance costs, energy efficiency, downtime, and productivity factors. By analyzing these factors, businesses can make more informed decisions about which equipment to purchase and can optimize their overall costs over the long term. This can lead to improved efficiency, reduced costs, and increased profitability.

When building or specifying industrial equipment for a manufacturing environment, it is important to consider the total cost of ownership (TCO). TCO considers not only the upfront cost of purchasing the equipment, but also the cost of operating and maintaining it over its lifespan. This includes maintenance costs, energy efficiency, downtime, and productivity factors. By analyzing these factors, businesses can make more informed decisions about which equipment to purchase and can optimize their overall costs over the long term. This can lead to improved efficiency, reduced costs, and increased profitability.

Don't see what you need?

Please contact us!

We have many great partners and would be happy to make a recommendation to a reliable source if we don't have what you need.

.jpg?width=472&height=321&name=KDS-FP_2_780X530%20(1).jpg)