Cost Reduction

Cost Reduction Strategies for Designing Industrial Equipment to Optimize Cost Savings

At Dynamic, our extensive experience in machine design and industrial control for production environments has given us unique insights into effective cost-reduction strategies. By prioritizing certain factors from the outset, we can help you significantly lower costs across various stages of your equipment's lifecycle, benefiting both you and your end users.

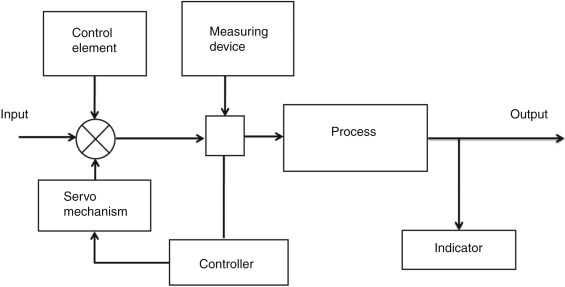

WE APPROACH COST OPTIMIZATION THROUGH STRATEGIC DESIGN AND PLANNING:

Material Selection

Choosing the right materials is crucial for balancing cost, performance, and durability. We leverage our industry knowledge to select cost-effective materials that meet your equipment requirements without compromising quality, ensuring a balance between initial costs and long-term value.

%20Components.jpg?width=220&height=220&name=Power%20Factor%20Correction%20(PFC)%20Components.jpg)

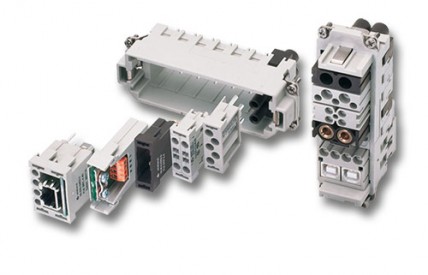

Component Standardization

By standardizing components across your equipment, we can minimize inventory costs, simplify maintenance, and enhance the scalability of your production. Standardization also facilitates easier upgrades and replacements, reducing long-term operational costs.

Design Simplicity

Simplicity in design does not just reduce manufacturing costs; it also makes your machines more reliable and easier to maintain. We focus on creating streamlined, efficient designs that achieve your objectives with fewer parts and less complexity.

Process Efficiency

Efficient design and manufacturing processes are key to reducing waste and minimizing costs. Our approach includes optimizing workflow, reducing lead times, and implementing lean manufacturing principles to ensure that your project is completed on time and within budget.

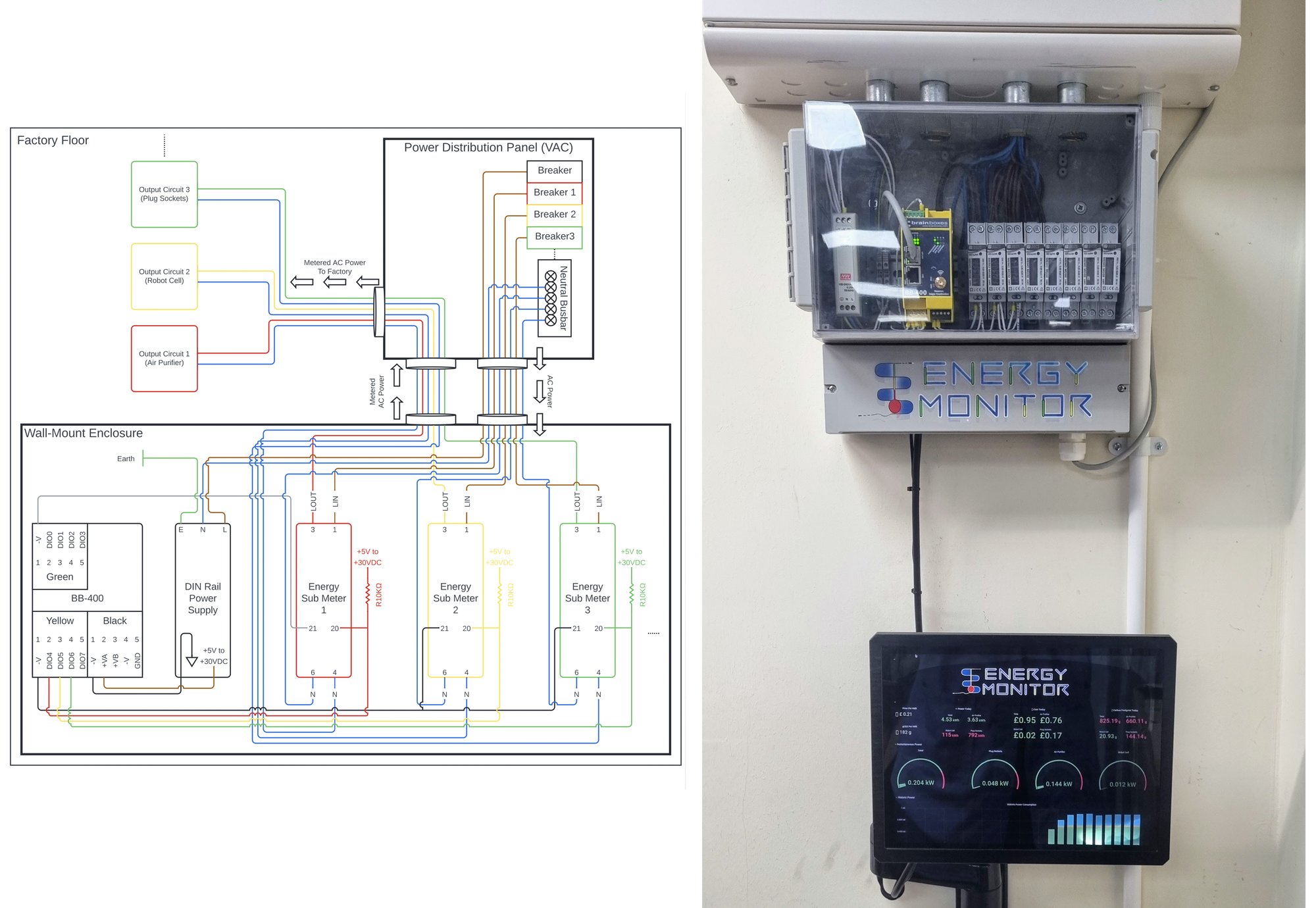

Energy Efficiency

Designing for energy efficiency is not only environmentally responsible but also reduces operating costs for end users. We incorporate energy-saving features and technologies to minimize the consumption of electricity and other resources.

Life Cycle Cost Analysis

We understand the component life cycle and how to optimize this for your machine's life span. Understanding the total cost of ownership includes considering maintenance, operational expectancy, and end-of-life costs, and ensuring that decisions made during the design phase contribute to long-term savings.

Modular Design

Modular designs offer flexibility for both manufacturing and end use, allowing for easier customization and scalability. This approach can reduce development and production costs and make future upgrades simpler and more cost-effective.

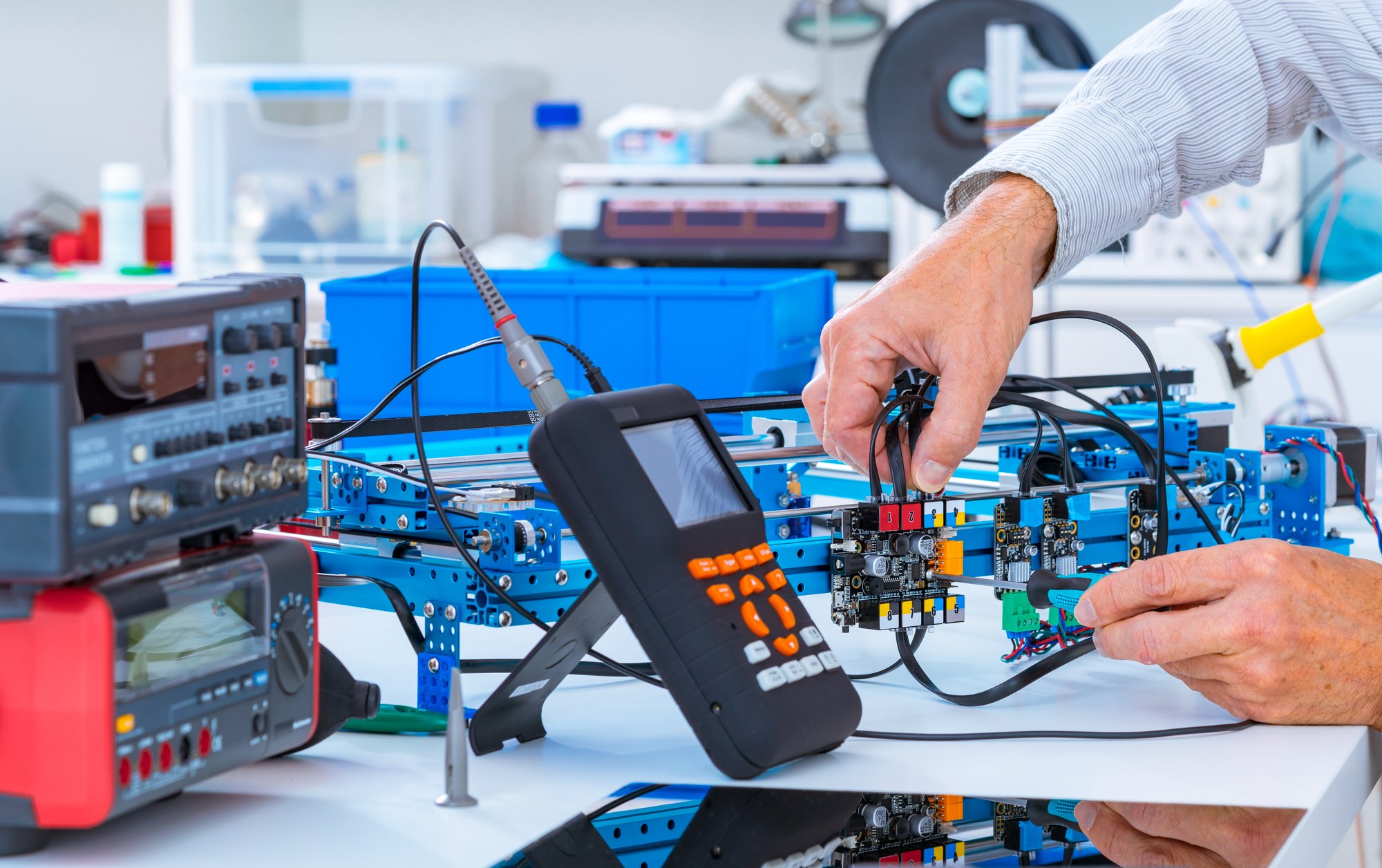

Prototyping and Testing

Investing in prototyping and rigorous testing helps avoid costly design errors and ensures that the final product meets all performance and safety standards. This upfront investment saves significant rework and compliance costs down the line.

Regulatory Compliance

Ensuring compliance with relevant regulations, such as UL and NFPA from the design stage can avoid costly fines and redesigns. Our expertise in regulatory standards helps streamline the design and compliance process to avoid additional costs.

At Dynamic, we believe that a strategic approach to design and manufacturing can significantly reduce the cost of industrial equipment.

By prioritizing these factors from the early stages of a project, we help you optimize investment, enhance efficiency, and deliver superior value to You and your customers.

Let's build smarter, together!